A test method for interfacial shear strength of thermosetting resin matrix composites

A technology of interfacial shear strength and composite materials, applied in the direction of applying stable shear force to test material strength, material resistance, and analysis of materials, can solve the difficulty of strength value, increase the difficulty and uncertainty of testing, and the difficulty of size Control and other issues, achieve the effect of low sample size requirements, promote research and application, and shorten the evaluation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for testing the interfacial shear strength of thermosetting resin-based composite materials based on the magnetic fiber stress impedance effect, comprising the following steps:

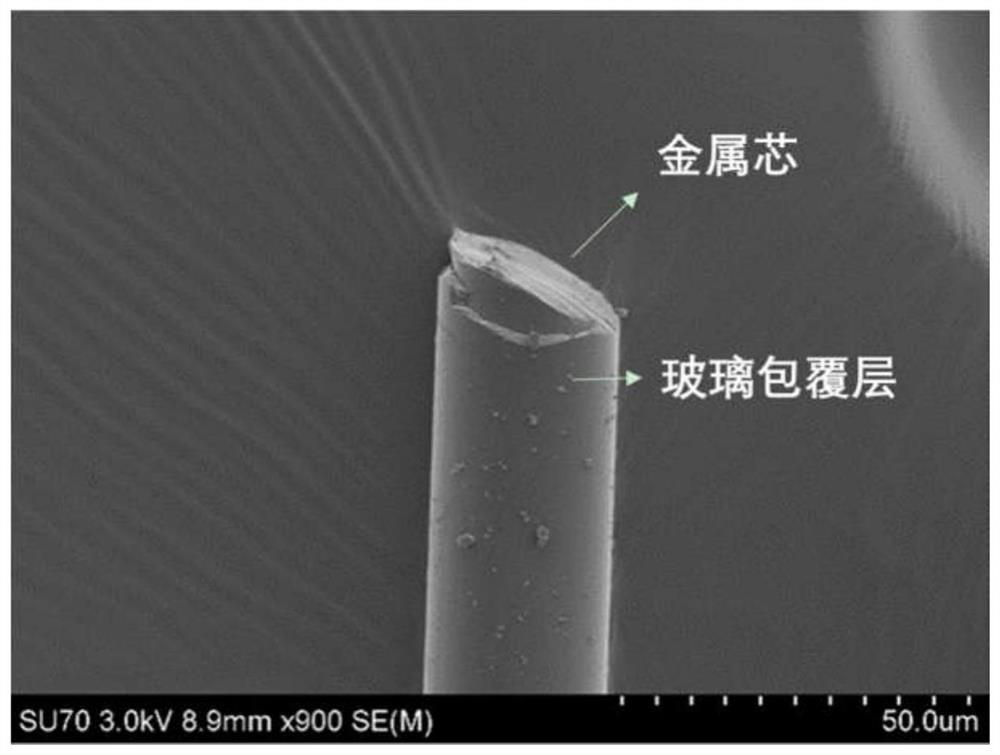

[0055] (1) Adopt 3% silane coupling agent-ethanol solution to process amorphous alloy fiber (this embodiment adopts glass-coated magnetic fiber, its SEM figure is as attached figure 1 ), the fiber composition is Co-Fe-Si-B-Ni-Mo, the diameter is 24.65 μm, and the surface has a 2 μm thick glass coating layer. After ultrasonic treatment for 20 minutes, it is placed in an oven at 100 ° C for 1.5 hours; after drying, the The amorphous alloy fiber is fixed on a hollow aluminum alloy rectangular frame; under an optical microscope, use a slender needle to drop the prepared cyanate resin acetone solution on the amorphous alloy fiber, and the resin forms a spindle under the action of surface tension microspheres, as attached figure 2 ;

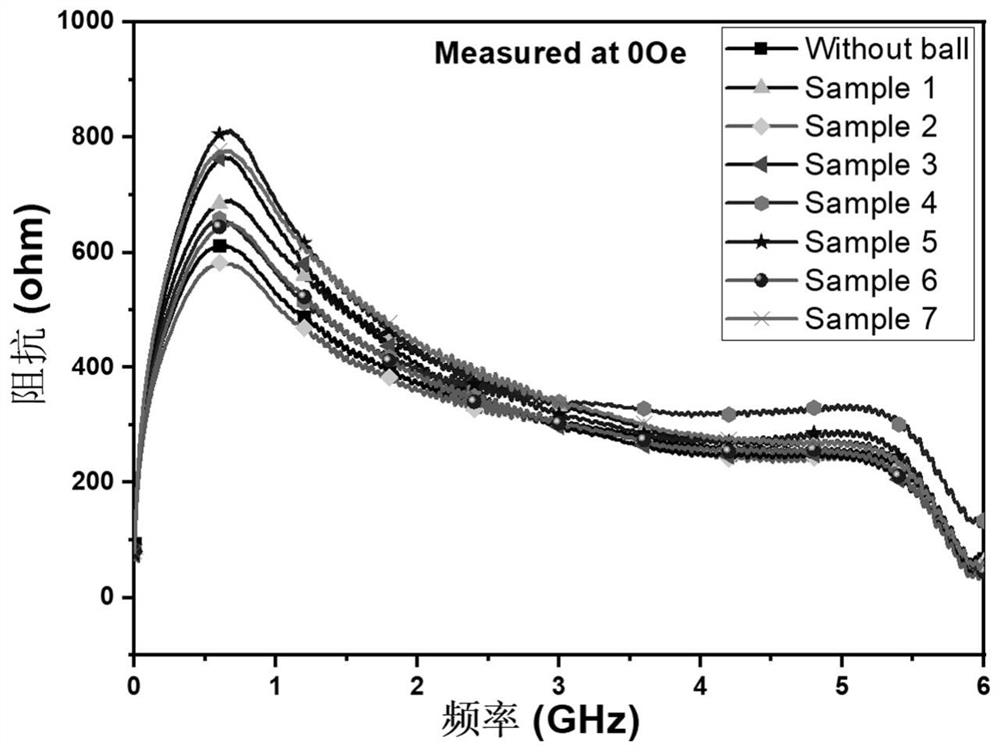

[0056] (2) After the oven is cured, the amorphous alloy ...

Embodiment 2

[0061] The difference between this embodiment and embodiment 1 is that the thermosetting resin is replaced by phenolic resin, and other magnetic fiber materials, processing methods and testing steps are the same as in embodiment 1. According to the absolute value of the slope to the descending section fitted from the impedance change-embedding length relationship map|k 2 | is 1.14211, while the resin modulus of elasticity is 4000MPa, the calculated interface shear strength of Example 2 is 68.15MPa, and the interface shear strength recorded by the traditional micro-debonding method is 70.3MPa.

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 is that the thermosetting resin is replaced by epoxy resin, and other magnetic fiber materials, processing methods and testing steps are the same as in Embodiment 1. According to the absolute value of the slope to the descending section fitted from the impedance change-embedding length relationship map|k 3 | is 1.496551, the resin modulus of elasticity is 4200MPa, and the interfacial shear strength obtained by calculating Example 3 is 78.88MPa, and the interfacial shear strength measured by the traditional micro-debonding method is 79.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com