Anti-corrosion film-coating coating for heat exchanger copper pipe and film coating process of anti-corrosion film-coating coating

A heat exchanger and anti-corrosion technology, which is applied in anti-corrosion coatings, heat exchange equipment, polyester coatings, etc., can solve the problems of poor waterproof and anti-corrosion ability of the protective film, poor heat transfer effect, etc., and achieve improved scratch resistance , Improve environmental protection, improve the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

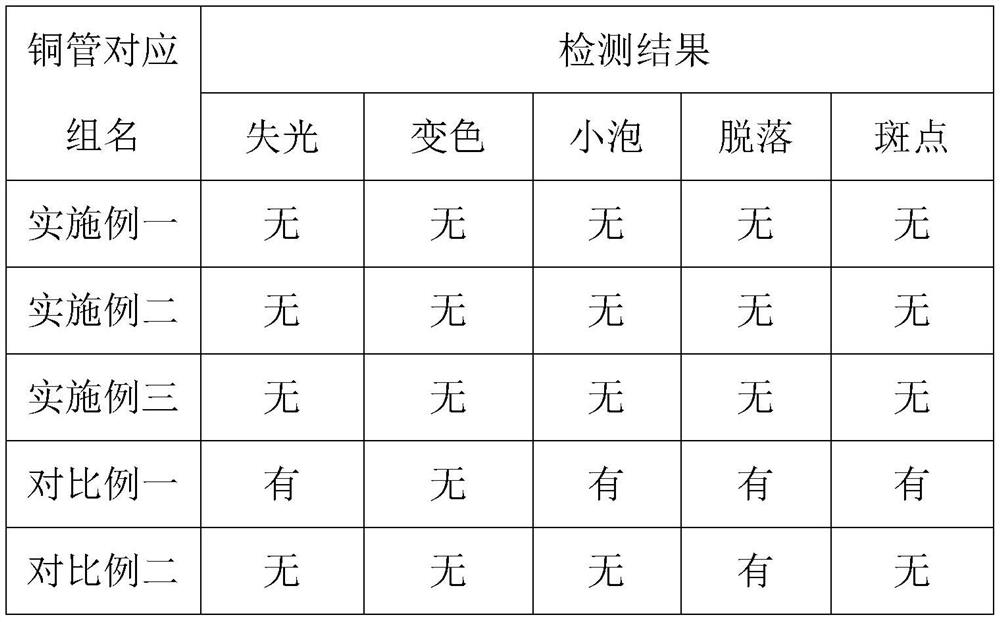

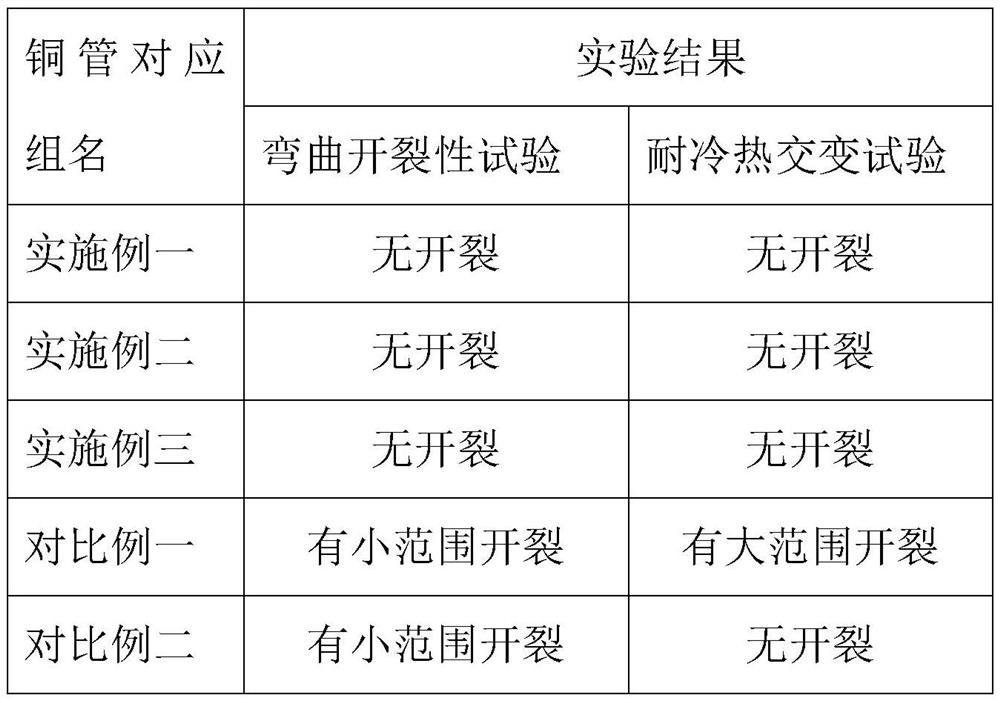

Examples

Embodiment 1

[0028] A film coating process of an anti-corrosion film coating paint for heat exchanger copper tubes, comprising the following steps:

[0029] S1. Clean the inside of the copper tube of the heat exchanger. The specific operation is: pour the cleaning agent from one end of the copper tube of the heat exchanger, and let the other end out, clean for 5 seconds, and blow out the residual cleaning agent with 0.3 kPa high-pressure air , and then pass clean water from one end of the heat exchanger copper tube, and pass it out from the other end. After cleaning for 5 seconds, use 0.3 kPa high-pressure air to blow out the residual clean water. After cleaning, use a baking oven to bake at a temperature of 100 degrees Celsius. Dry;

[0030] S2. Prepare the main agent and auxiliary materials. The main agent includes the following raw materials in mass percentage: 12% special polyester resin, 30% modified silicone resin, 2% epoxy resin, 28% titanium dioxide, 0.1% U carbon black, Abrasive ...

Embodiment 2

[0034] A film coating process of an anti-corrosion film coating paint for heat exchanger copper tubes, comprising the following steps:

[0035] S1. Clean the inside of the copper tube of the heat exchanger. The specific operation is: pour the cleaning agent from one end of the copper tube of the heat exchanger, and let the other end out, clean for 8 seconds, and blow out the residual cleaning agent with 0.5 kPa high-pressure air , then pass clean water from one end of the heat exchanger copper tube, and pass it out from the other end. After cleaning for 15 seconds, use 0.5 kPa high-pressure air to blow out the residual clean water. After cleaning, use a baking oven to bake at a temperature of 150 degrees Celsius. Dry;

[0036]S2. Prepare the main agent and auxiliary materials. The main agent includes the following raw materials in mass percentage: 10% special polyester resin, 30% modified silicone resin, 2.3% epoxy resin, 23% titanium dioxide, 0.2% U carbon black, Abrasive ma...

Embodiment 3

[0040] A film coating process of an anti-corrosion film coating paint for heat exchanger copper tubes, comprising the following steps:

[0041] S1. Clean the inside of the copper tube of the heat exchanger, the specific operation is: pour the cleaning agent from one end of the copper tube of the heat exchanger, and let the other end out, clean for 10 seconds, and blow out the residual cleaning agent with 0.6 kPa high-pressure air , and then pass clean water from one end of the heat exchanger copper tube, and pass it out from the other end. After cleaning for 20 seconds, use 0.6 kPa high-pressure air to blow out the residual clean water. After cleaning, use a baking oven to bake at a temperature of 200 degrees Celsius. Dry;

[0042] S2. Prepare the main agent and auxiliary materials. The main agent includes the following raw materials in mass percentage: 12% special polyester resin, 30% modified silicone resin, 3% epoxy resin, 25% titanium dioxide, 0.3% U carbon black, Abrasiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com