Hollow ball ceramic fiber brick and preparation method thereof

A ceramic fiber and hollow sphere technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of poor strength, easy formation of gaps, high thermal conductivity, long service life, improved thermal shock resistance, and reduced thermal conductivity. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

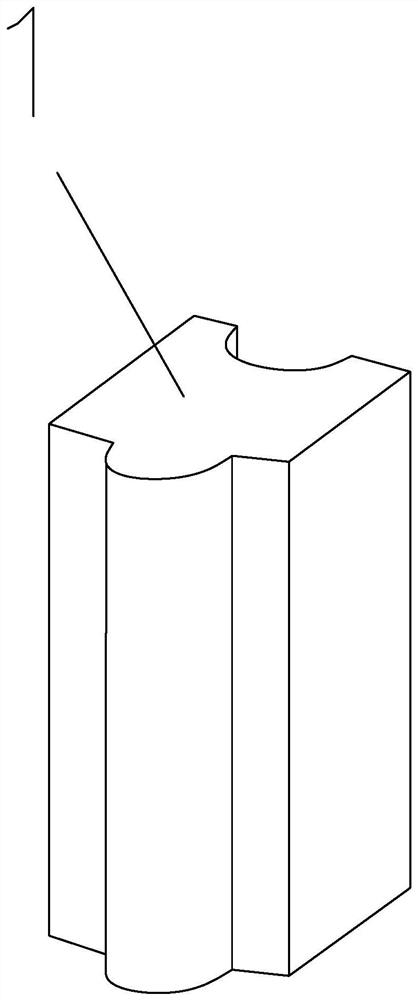

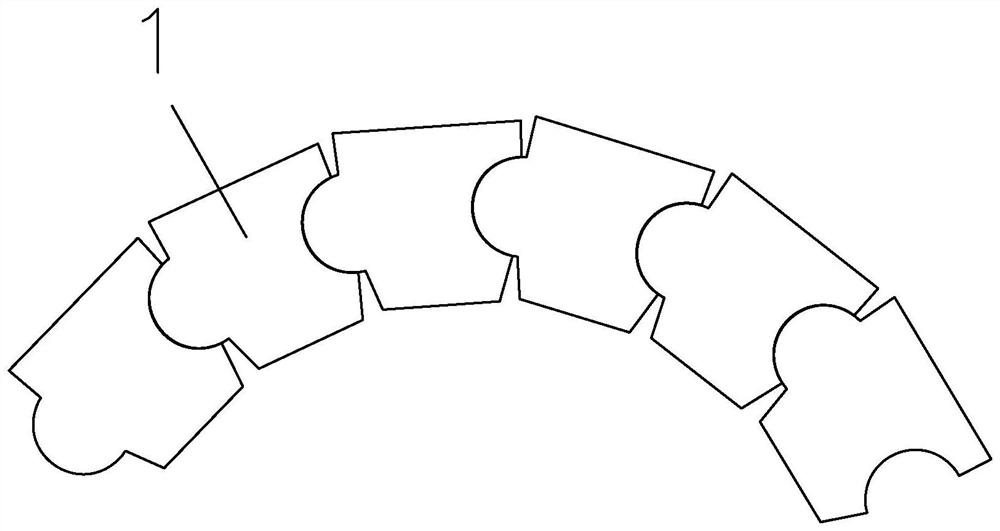

Image

Examples

preparation example Construction

[0027] A preparation method of hollow ball ceramic fiber brick, comprising the following steps:

[0028] Step 1: Prepare materials, prepare 59~65% alumina hollow spheres, 30~35% high-purity alumina powder, 2~5% polycrystalline mullite fiber, 1~3% high-temperature adhesive for coating The glass-coated slurry on the outer surface of the brick body 1, the glass-coated slurry is usually made of silicon dioxide, aluminum oxide, quicklime, magnesium oxide, potassium oxide and sodium oxide ball milled, melted and fired, and then crushed and ground after cooling Prepared by mixing barium sulfate solution;

[0029] Step 2: Carry out high-temperature heat treatment on the polycrystalline mullite fiber at a temperature of 1280-1500 ° C, and keep it warm for more than 1 hour, uniformly crush the heat-treated polycrystalline mullite fiber for use, and add water to the high-temperature adhesive to prepare The solution with a mass fraction lower than 40% is ready for use, and the high-tempe...

Embodiment 1

[0038] Embodiment 1: The component distribution ratio is: 60% alumina hollow sphere; 35% high-purity alumina powder; 2% polycrystalline mullite fiber; 3% high-temperature binder.

[0039]The density of the sample brick after production and sintering: 1600kg / m³, after testing, the maximum service temperature can reach 1700°C, and the linear shrinkage test is carried out at 1600°C*2hr. , in line with heat resistance requirements.

[0040] Comparison of thermal shock resistance test: Put the prepared hollow ball ceramic fiber brick into a high-temperature furnace, heat it to 1200°C, keep the temperature for 1 hour, open the furnace door, pull out the ceramic fiber board, expose it to the air, and cool it to After the surface temperature is 200°C, put it into the furnace and heat up rapidly (30°C / min heating), and repeat the steps.

[0041] Test results: The new hollow ball ceramic fiber brick can be subjected to more than 6 times of rapid cooling and rapid heating tests at a tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com