Method and device for enhanced separation in preparation of isocyanate

An isocyanate and enhanced separation technology, which is applied in the purification/separation of isocyanate derivatives, chemical instruments and methods, and preparation of isocyanate derivatives, etc., can solve the problems of difficulty in product concentration and separation, complex process routes, environmental pollution, etc. To achieve the effect of improving the reaction yield and the yield of the equipment, the equipment is simple, and the zero emission requirements are achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

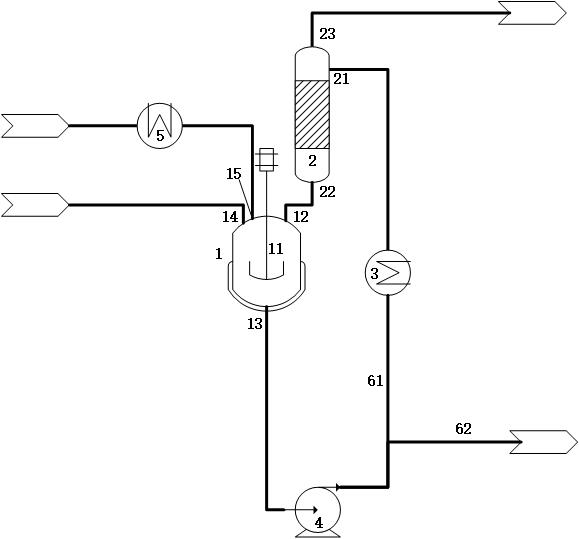

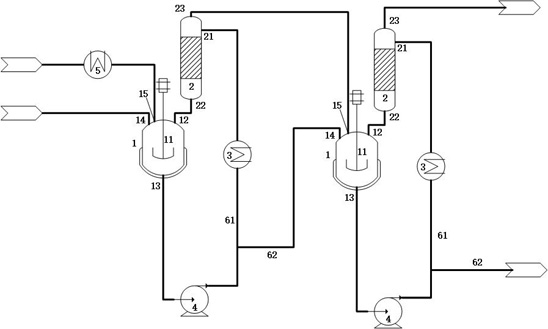

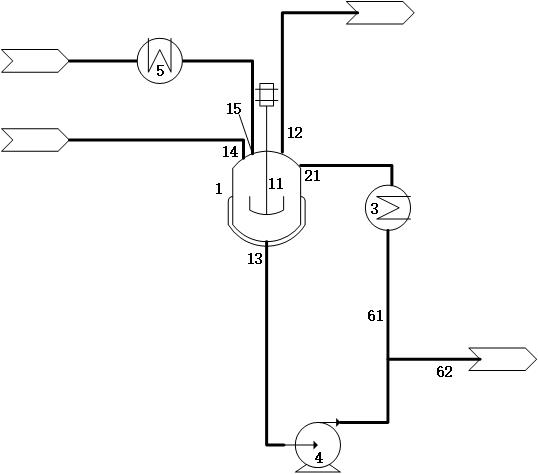

[0078] This embodiment provides a device for strengthening separation in the preparation of isocyanates, such as figure 1 As shown, the device includes: a reaction device 1 and a separation device 2, the reaction device 1 is a reactor, and the separation device 2 is a rectification column.

[0079] The upper part of the reaction device 1 is provided with a reaction purge gas outlet 12 , and the reaction purge gas outlet 12 is connected to the bottom inlet 22 of the separation device 2 . The bottom of the reaction device 1 is provided with a first material outlet 13, and the first material outlet 13 is connected with a first stream pipeline 61 and a second stream pipeline 62, and the first stream pipeline 61 is connected to the separating device 2. The upper entrance 21 is connected. The first heat exchange device 3 is arranged on the first stream pipe 61 . The top of the separation device 2 is provided with a purge tail gas outlet 23 .

[0080] The top of the reaction devic...

Embodiment 2

[0083] This embodiment provides a device for strengthening separation in the preparation of isocyanate, which is the same as that of Embodiment 1 except that the second heat exchange device is not provided.

Embodiment 3

[0085] This embodiment provides a device for strengthening separation in the preparation of isocyanate. The device is the same as that of Embodiment 1 except that the separation device is a rectification tower and a packed column is arranged in the tower as a separation component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com