High-toughness and high-cohesiveness C150-strength ultrahigh-strength fiber concrete and preparation method thereof

A fiber-reinforced concrete and high-bonding technology, which is applied in clay preparation equipment, chemical instruments and methods, and climate sustainability, can solve the problems of less active groups, affecting the uniform dispersion of carbon nanotubes, and low relative solubility. Achieve the effects of increasing cohesiveness, reducing cost and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

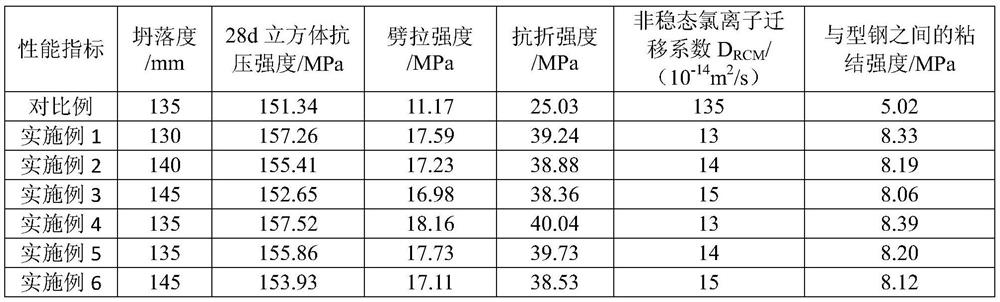

Examples

Embodiment 1

[0100] 1) Add 14 parts by mass of water reducer and 25 parts by mass of hydroxyl-modified single-walled carbon nanotube dispersion into two-thirds of the total water, which is recorded as mixed solution 1; 11 parts of shrinkage reducing agent and 2.4 parts of antifoaming agent are added to one-third of the total water volume, which is recorded as mixed solution 2, and 16.5 parts of carboxy-modified polyvinyl alcohol polymers are prepared for later use, and the total water volume is 105 Wherein, the carboxy-modified polyvinyl alcohol polymer is prepared from raw materials according to mass percentage: carboxy-modified polyvinyl alcohol 38.5%, water 60%, polyacrylate defoamer 1.5%;

[0101] 2) Divide 5.5 parts of ramie fiber, 985 parts of gravel, 715 parts of sand, 460 parts of cement, 75 parts of fly ash, 70 parts of straw ash, 40 parts of silica fume, 3.8 parts of nano silicon, and 9.8 parts of basalt fiber into Three parts, then spread a part of ramie fiber and basalt fiber e...

Embodiment 2

[0110] 1) Add 15 parts by mass of water reducer and 27 parts by mass of hydroxyl-modified single-walled carbon nanotube dispersion into two-thirds of the total water, which is recorded as mixed solution 1; 12 parts of shrinkage reducing agent and 2.2 parts of antifoaming agent are added into the water of one-third of the total water volume, which is recorded as mixed solution 2. After the preparation of 18 parts of carboxy-modified polyvinyl alcohol polymer is completed, the total water volume is 110 Wherein, carboxy-modified polyvinyl alcohol polymer is prepared from raw materials according to mass percentage: carboxy-modified polyvinyl alcohol 39%, water 60%, polyacrylate defoamer 1%;

[0111] 2) Divide 5.6 parts of ramie fiber, 985 parts of gravel, 710 parts of sand, 465 parts of cement, 80 parts of fly ash, 65 parts of straw ash, 43 parts of silica fume, 4.4 parts of nano silicon, and 10 parts of basalt fiber into Three parts, then spread a part of ramie fiber and basalt f...

Embodiment 3

[0119] 1) Add 14 parts by mass of water reducer and 30 parts by mass of hydroxyl-modified single-walled carbon nanotube dispersion to two-thirds of the total water, and record it as mixed solution 1; Add 11.5 parts of shrinkage reducing agent and 2.6 parts of defoamer to one-third of the total water volume, and record it as mixed solution 2. After preparing 16.5 parts of carboxy-modified polyvinyl alcohol polymers, the total water volume is 110 Wherein, the carboxy-modified polyvinyl alcohol polymer is prepared from raw materials according to mass percentage: carboxy-modified polyvinyl alcohol 37%, water 62%, polyacrylate defoamer 1%;

[0120] 2) Divide 5.6 parts of ramie fiber, 985 parts of gravel, 715 parts of sand, 470 parts of cement, 85 parts of fly ash, 68 parts of straw ash, 40 parts of silica fume, 4.4 parts of nano silicon, and 10 parts of basalt fiber into Three parts, then spread a part of ramie fiber and basalt fiber evenly in the disc mixer, and then place a part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com