Fluorite structure high-entropy oxide powder for thermal barrier coating and preparation method of fluorite structure high-entropy oxide powder

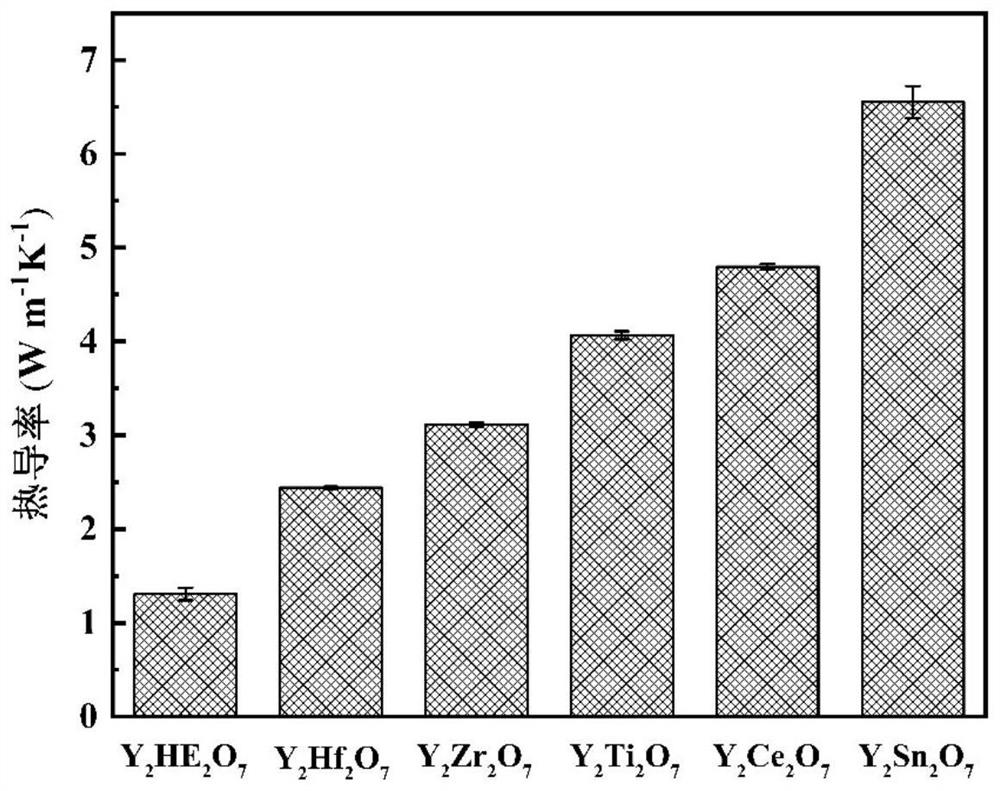

A technology of fluorite structure and thermal barrier coating is applied in the field of fluorite structure high-entropy oxide powder for thermal barrier coating and its preparation, which can solve the problem of enhanced phonon and defect scattering, can not meet the needs of gas turbine service, Low thermal expansion coefficient, etc., to achieve the effects of excellent comprehensive mechanical properties, shortened mean free path, and high thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

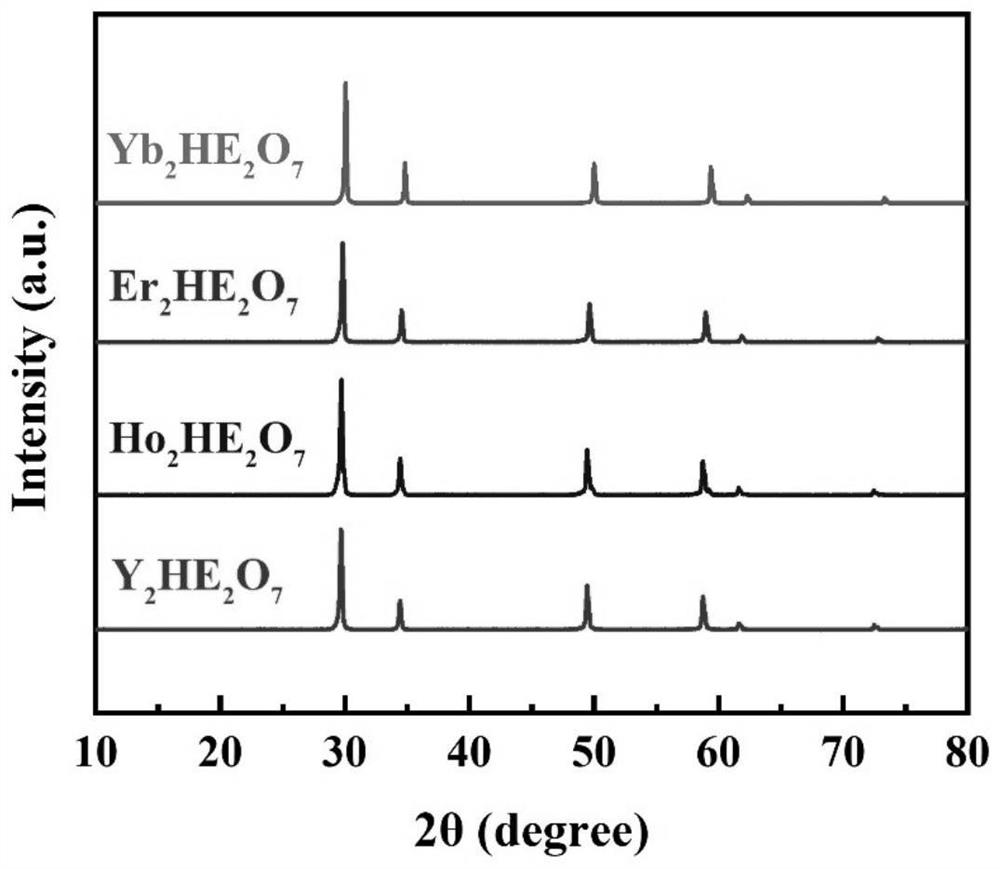

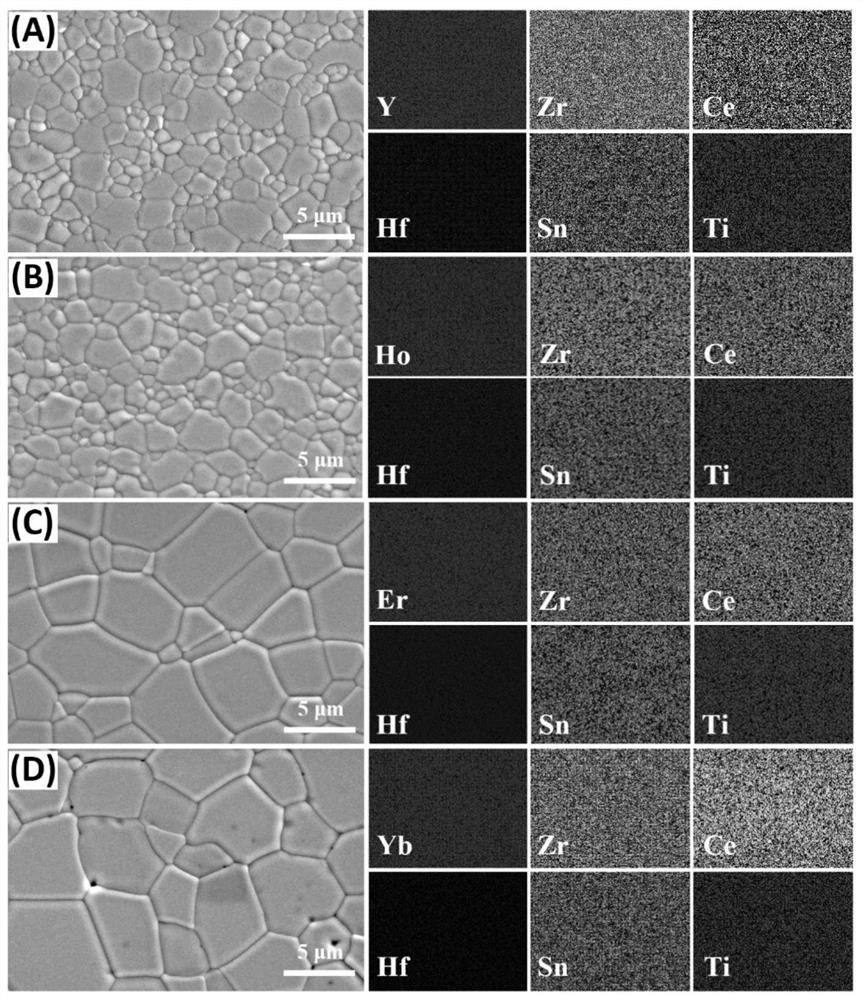

[0032] This example provides a fluorite-structured high-entropy oxide powder for thermal barrier coatings and its preparation method. The specific steps are as follows:

[0033] Step 1, set Y 2 o 3 , CeO 2 , ZrO 2 , HfO 2 , SnO 2 、TiO 2 The original powder is heated to 900°C for 2 hours to remove moisture and organic impurities. After cooling, the powder is weighed according to the molar ratio of 5:2:2:2:2:2 for batching, and the mixed powder is placed in a planetary ball mill to Water and ethanol were used as the medium, and zirconia balls were used as the grinding balls, and ball milled at a speed of 500r / min for 12h.

[0034] Step 2: Dry the ball-milled powder at 80°C for 12h, place it in a muffle furnace, and heat it at 5°C / min to 1200°C for 5h in an air atmosphere.

[0035] Step 3: Put the calcined powder in a planetary ball mill, use absolute ethanol as the medium, and zirconia balls as the grinding balls, and ball mill at a speed of 500 r / min for 24 hours.

[00...

Embodiment 2

[0039] This example provides a fluorite-structured high-entropy oxide powder for thermal barrier coatings and its preparation method. The specific steps are as follows:

[0040] Step 1, the Ho 2 o 3 , CeO 2 , ZrO 2 , HfO 2 , SnO 2 、TiO 2 The original powder is heated to 1000°C for 1 hour to remove moisture and organic impurities. After cooling, the powder is weighed according to the molar ratio of 5:2:2:2:2:2 for batching, and the mixed powder is placed in a planetary ball mill to Water and ethanol were used as the medium, and zirconia balls were used as the grinding balls, and ball milled at a speed of 450r / min for 16h.

[0041] Step 2: Dry the ball-milled powder at 80°C for 12h, place it in a muffle furnace, and heat it at 5°C / min to 1300°C for 3h in an air atmosphere.

[0042] Step 3: Put the calcined powder in a planetary ball mill, use absolute ethanol as the medium, and zirconia balls as the grinding balls, and ball mill at a speed of 500 r / min for 20 hours.

[0...

Embodiment 3

[0046] This example provides a fluorite-structured high-entropy oxide powder for thermal barrier coatings and its preparation method. The specific steps are as follows:

[0047] Step one, put Er 2 o 3 , CeO 2 , ZrO 2 , HfO 2 , SnO 2 、TiO 2 The original powder is heated to 800°C for 5 hours to remove moisture and organic impurities. After cooling, the powder is weighed according to the molar ratio of 5:2:2:2:2:2 for batching, and the mixed powder is placed in a planetary ball mill to remove Ionized water was used as the medium, and zirconia balls were used as the grinding balls, and the ball milled at a speed of 400r / min for 20h.

[0048] Step 2: Dry the ball-milled powder at 70°C for 24h, place it in a muffle furnace, and heat it at 2°C / min to 1100°C for 6h in an air atmosphere.

[0049] Step 3, put the calcined powder in a planetary ball mill, use deionized water as the medium, and zirconia balls as the grinding balls, and ball mill at a speed of 400 r / min for 24 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com