Composite osteochondral scaffold as well as preparation method and application thereof

An osteochondral and cartilage layer technology, applied in the field of 3D printing materials, can solve the problems of single biological scaffold, single material structure, and differences in mechanical and biological properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

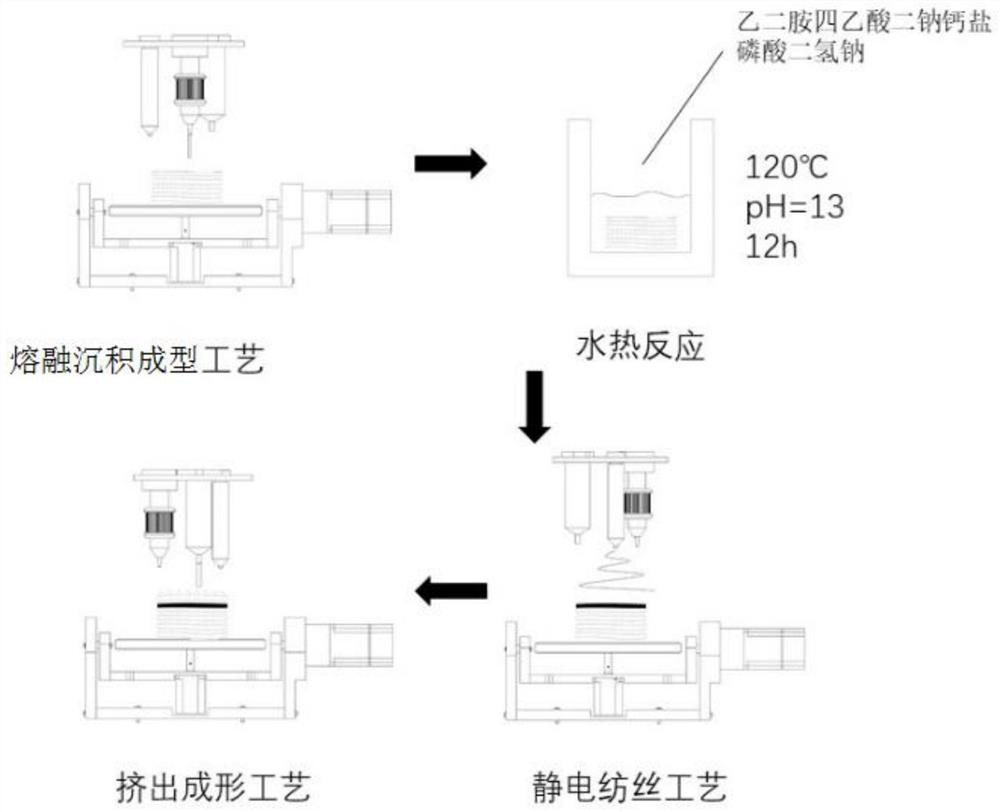

[0042] The present invention also provides a method for preparing the composite osteochondral scaffold described in the above technical solution, comprising the following steps:

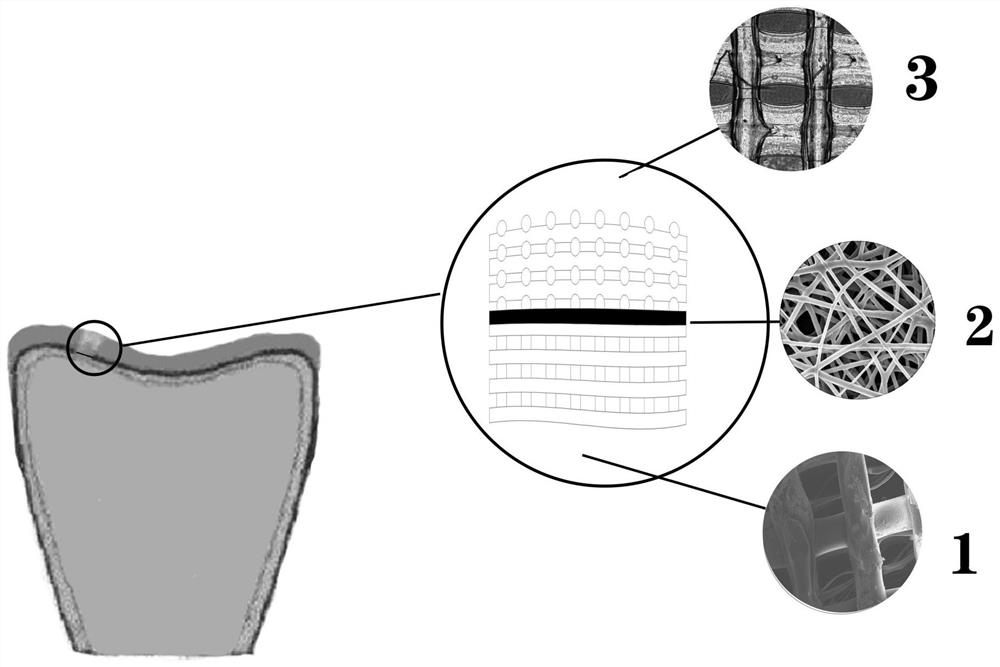

[0043] Using fused deposition modeling process to 3D print polyetheretherketone into subchondral bone layer;

[0044] Coating a biocompatible solution on the surface of the subchondral bone layer by a hydrothermal method to form a biocompatible layer;

[0045] Using an electrospinning process to 3D print a fibrous film-like transition layer on the surface of the biocompatible layer;

[0046] A cartilage layer with a network structure is 3D printed on the surface of the transition layer by an extrusion molding process, and the extruded raw material contains cartilage matrix and biological factors, and the cartilage matrix is a hydrogel material.

[0047] The invention utilizes a fused deposition modeling process to 3D print polyetheretherketone into a subchondral bone layer. In the present inventi...

Embodiment 1

[0073] CT scans the point cloud data of the articular cartilage defect, converts the point cloud data obtained from the CT scan into a solid model through reverse design, and builds a three-dimensional model of the defect with reference to the complete cartilage tissue structure, and adds boundary conditions to the obtained model, and conducts limited Meta-analysis to obtain its stress-strain distribution; according to the stress-strain distribution, the path planning for 3D printing of the subchondral bone model is carried out;

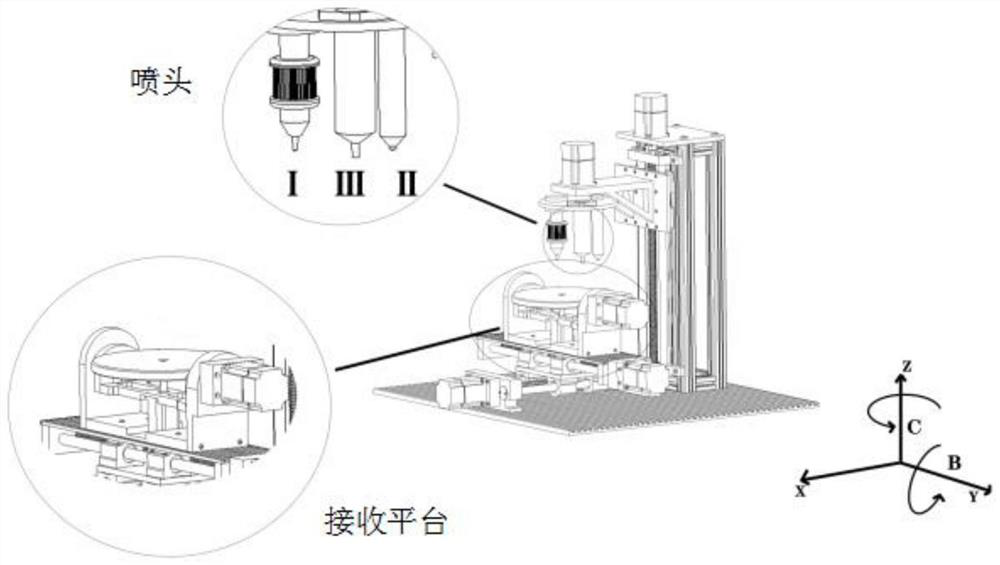

[0074] Nozzle I (nozzle diameter: 0.4mm) is loaded with polyether ether ketone, and the nozzle I moves in the three directions of x, y, and z, and cooperates with the rotation of the B-axis and C-axis of the receiving platform to print according to the planned printing path (the temperature of the fusion deposition 395°C) subchondral bone layer to obtain a reticular subchondral bone layer with a pore size of 800 μm;

[0075] Dissolve 3.75g of ethylened...

Embodiment 2

[0079] The composite osteochondral scaffold was prepared according to the method of Example 1, except that the temperature of the hydrothermal reaction was 180°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com