Magnetoresistive integrated stress sensor and preparation method and application thereof

A technology of stress sensor and magnetoresistance, which is applied in the field of magnetoresistance integrated stress sensor and its preparation, can solve the problems that the detection of stress magnitude and direction cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

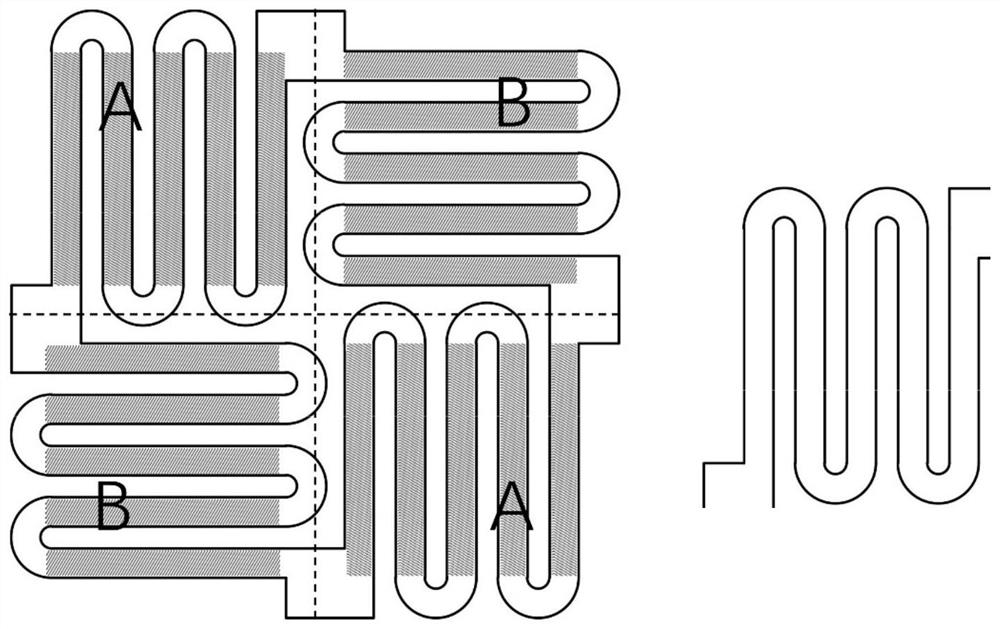

[0027] see figure 1 , a magnetoresistive integrated stress sensor, comprising: a substrate; a permanent magnetic thin film layer, the permanent magnetic thin film layer is on one side of the substrate; a piezoelectric thin film layer, the piezoelectric thin film layer is on the substrate on the other side relative to the permanent magnetic thin film layer , for outputting voltage under external stress; and a metal electrode, the metal electrode is on the piezoelectric thin film layer.

[0028] The role of the base is to support the magnetic film layer and the piezomagnetic film layer. The permanent magnetic film applies a static magnetic field, which is equivalent to a magnet, so that the magnetic moment in the piezomagnetic film faces a specific direction. Once there is an external stress, the pressure of the piezomagnetic film changes. The distribution of magnetic moment orientation can test the direction of external stress. When the piezomagnetic film layer is subjected to...

Embodiment 2

[0041]A method for preparing a magnetoresistive integrated stress sensor, comprising: fixing a permanent magnetic thin film layer on a clean substrate; fixing a piezomagnetic thin film layer on the other side of the clean substrate relative to the fixed permanent magnetic thin film material; Photolithographic bridges and metal electrodes are grown on the piezoelectric thin film layer; negative photoresist photolithographic electrode patterns are used at both ends of the bridge, and the negative photoresist is peeled off to connect with the metal electrodes after the electrode pattern is formed.

[0042] The specific preparation method is as follows: cleaning the substrate; using electroplating, sputtering or permanent magnet sheet pasting on the substrate to form a permanent magnetic material layer; using magnetron sputtering, evaporation, chemical plating, laser pulse deposition or molecular beam epitaxy on the front of the substrate Growth of piezoelectric thin film material,...

Embodiment 3

[0045] Embodiment 3: Application of a magnetoresistive integrated stress sensor, based on the magnetoresistive integrated stress sensor used in medical health monitoring, restaurant occupancy monitoring, automotive electronics, wearable electronic devices, smart home and industrial robots .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com