Nuclear-irradiation-resistant reinforced high-temperature-resistant resonant quartz temperature sensor

A technology for temperature sensors and anti-nuclear radiation, applied in thermometers, thermometers with directly heat-sensitive electric/magnetic elements, and parts of thermometers, can solve the problem that the resolution, accuracy and long-term stability are not as good as thickness cutting Variable vibration mode, strong anti-nuclear radiation ability, unstable output signal, etc., to achieve the effect of novel working mode, less parasitic vibration mode, and less demanding process error requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

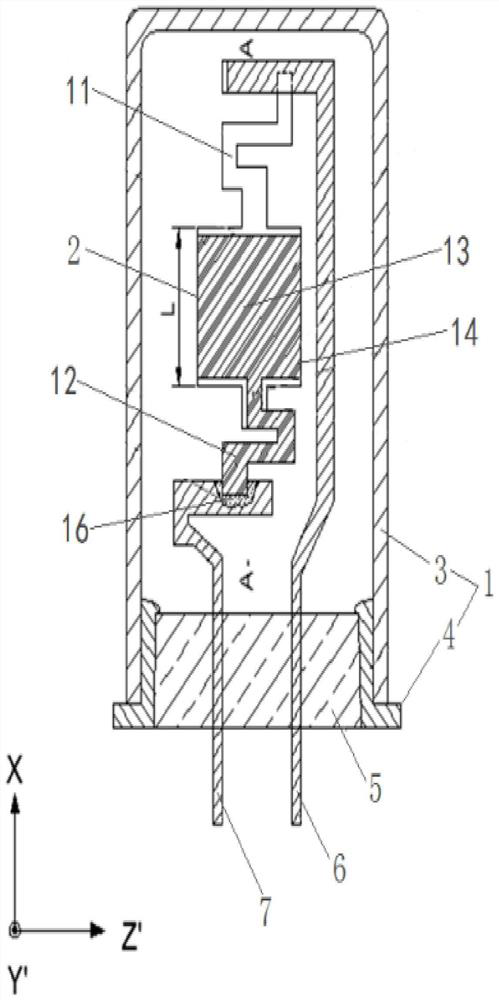

[0077] see figure 1 and figure 2 ,

[0078] A high-precision resonant quartz temperature sensor reinforced against nuclear radiation includes an integrated packaging component 1 and a thermosensitive quartz resonator 2 . The heat-sensitive quartz resonator 2 is placed inside the integrated packaging component 1; the integrated packaging component 1 includes a Kovar cap 3 with a tungsten-copper layer sputtered on the inner and outer surfaces and a tungsten-copper layer sputtered on the inner and outer surfaces. Kovar alloy socket 4;

[0079] The Kovar socket 4 with tungsten-copper layers sputtered on the inner and outer surfaces includes a glass frit insulator 5, a first pin 6, and a second pin 7;

[0080] The first pin 6 is connected to the first bus bar electrode 8 of the thermosensitive quartz resonator 2, and the second pin 7 is connected to the second bus bar electrode 9 of the thermosensitive quartz resonator 2; the first pin 6, the second The pins 7 are all made of ...

Embodiment 2

[0097] The difference between embodiment two and embodiment one is as follows:

[0098] The selected material is yxl(53°54 / ) quartz crystal, and m=0.76n, that is, a strip-shaped rectangular quartz sheet, plane shear vibration mode, and fundamental wave operation. Its first-order temperature coefficient can reach about 51.9×10-6 / ℃.

[0099] The raw material of the thermosensitive quartz resonator 2—the crystal material is an optical-grade artificial crystal material prepared with a slow growth rate, that is, the Q value of the raw material is 300×10 4 High-Q optical-grade artificial crystal materials are used, and then processed by electrocleaning to further improve its ability to withstand nuclear radiation and high temperature.

[0100] The multi-layer special alloy thin film is prepared by CVD chemical vapor deposition method; the first bus bar electrode 8 is electrically connected to the first pin 6 by using the thermocompression welding method, and the second bus bar e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com