High-strength polylactic acid-based electrospun nanofiber membrane and preparation method thereof

An electrospinning nanofiber, polylactic acid-based technology, applied in spinning solution preparation, textiles and papermaking, non-woven fabrics, etc., can solve the problem of affecting the biocompatibility of polylactic acid, enhance the content of nano-fillers, and increase the strength by a small margin. and other problems, to achieve the effect of saving dissolution time, good dispersibility, and small reduction in elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

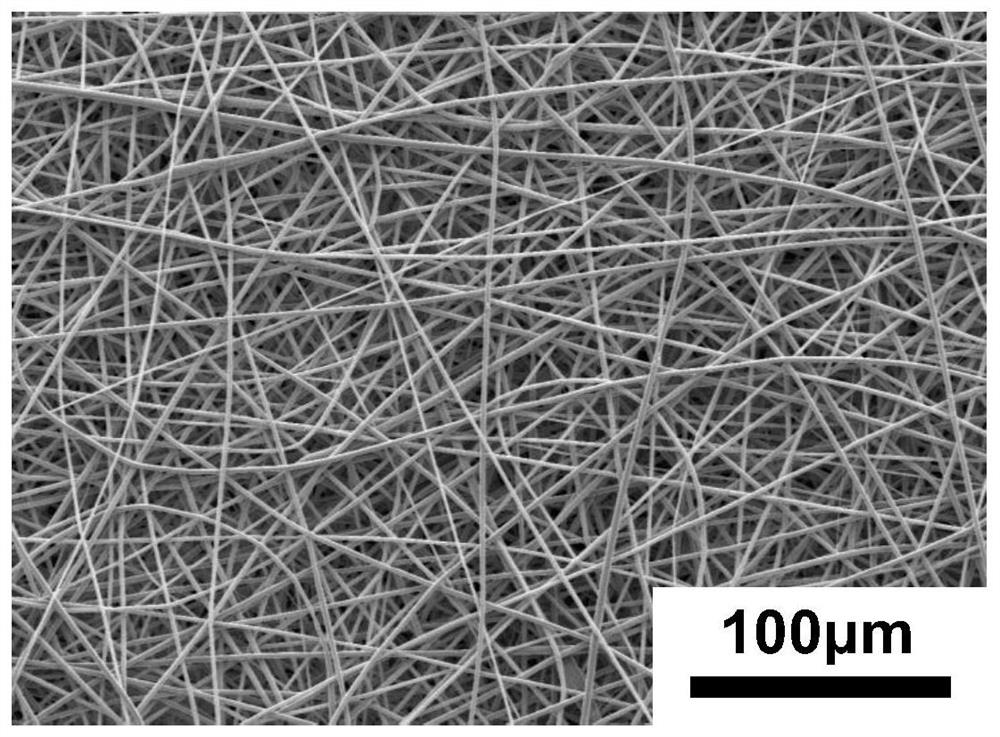

Embodiment 1

[0031] 1) Preparation of polylactic acid / cellulose nanocrystal spinning solution: Dissolve cellulose nanocrystals in a mixed solvent with a volume ratio of chloroform and acetone of 1:1 to configure the solution, and dissolve polylactic acid in chloroform and acetone with a volume ratio of Configure the solution in a 1:1 mixed solvent. After the cellulose nanocrystals are uniformly dispersed and the polylactic acid is completely dissolved, the above two solutions are mixed. After stirring evenly, the mass ratio of modified cellulose nanocrystals and polylactic acid is 0.5: 100 of electrospinning solution, and keep the concentration of polylactic acid in the mixed solution at 10wt%.

[0032]2) The electrospinning process of the spinning solution: the polylactic acid / modified cellulose nanocrystal spinning solution prepared in step 2) is placed in a fume hood for electrospinning, and the configured spinning solution is loaded into a syringe , the spinning voltage is set to 18kV,...

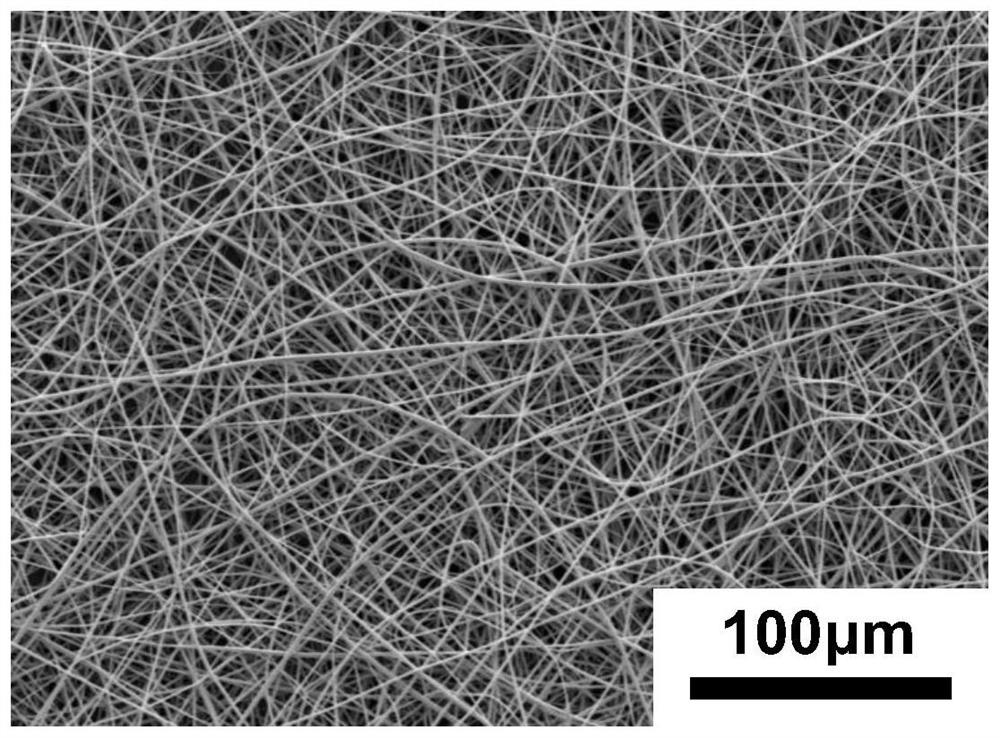

Embodiment 2

[0034] 1) Preparation of polylactic acid / cellulose nanocrystal spinning solution: Dissolve cellulose nanocrystals in a mixed solvent with a volume ratio of chloroform and acetone of 1:1 to configure the solution, and dissolve polylactic acid in chloroform and acetone with a volume ratio of Configure the solution in a 1:1 mixed solvent. After the cellulose nanocrystals are uniformly dispersed and the polylactic acid is completely dissolved, the above two solutions are mixed. After stirring evenly, the mass ratio of modified cellulose nanocrystals and polylactic acid is 1: 100 of electrospinning solution, and keep the concentration of polylactic acid in the mixed solution at 10wt%.

[0035] 2) The electrospinning process of the spinning solution: the polylactic acid / modified cellulose nanocrystal spinning solution prepared in step 2) is placed in a fume hood for electrospinning, and the configured spinning solution is loaded into a syringe , the spinning voltage is set to 18kV, ...

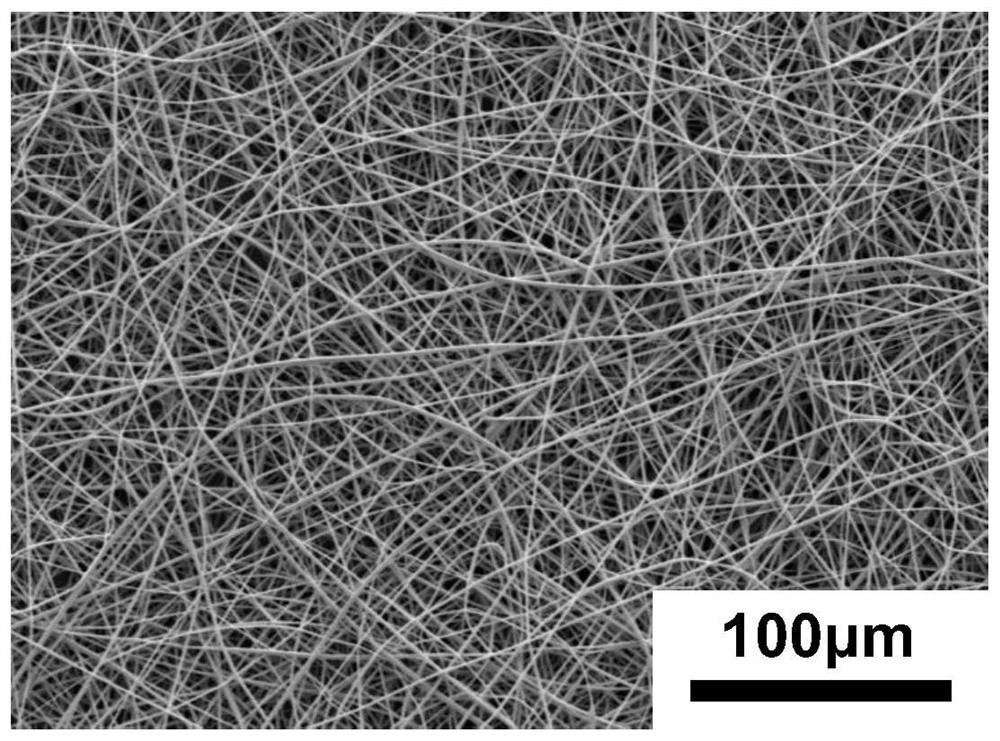

Embodiment 3

[0037] 1) Preparation of polylactic acid / cellulose nanocrystal spinning solution: Dissolve cellulose nanocrystals in a mixed solvent with a volume ratio of chloroform and acetone of 1:1 to configure the solution, and dissolve polylactic acid in chloroform and acetone with a volume ratio of Configure the solution in a 1:1 mixed solvent. After the cellulose nanocrystals are uniformly dispersed and the polylactic acid is completely dissolved, the above two solutions are mixed. After stirring evenly, the mass ratio of modified cellulose nanocrystals and polylactic acid is 3: 100 of electrospinning solution, and keep the concentration of polylactic acid in the mixed solution at 10wt%.

[0038] 2) The electrospinning process of the spinning solution: the polylactic acid / modified cellulose nanocrystal spinning solution prepared in step 2) is placed in a fume hood for electrospinning, and the configured spinning solution is loaded into a syringe , the spinning voltage is set to 18kV, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com