A kind of n800cf steel for pumped storage pressure steel pipe and its manufacturing method

A technology of pumped storage and pressure steel, which is applied in the manufacture of converters, etc., can solve problems such as plasticity index and low-temperature impact performance gap, and achieve the effects of reducing the total oxygen content, refining the structure, and eliminating hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

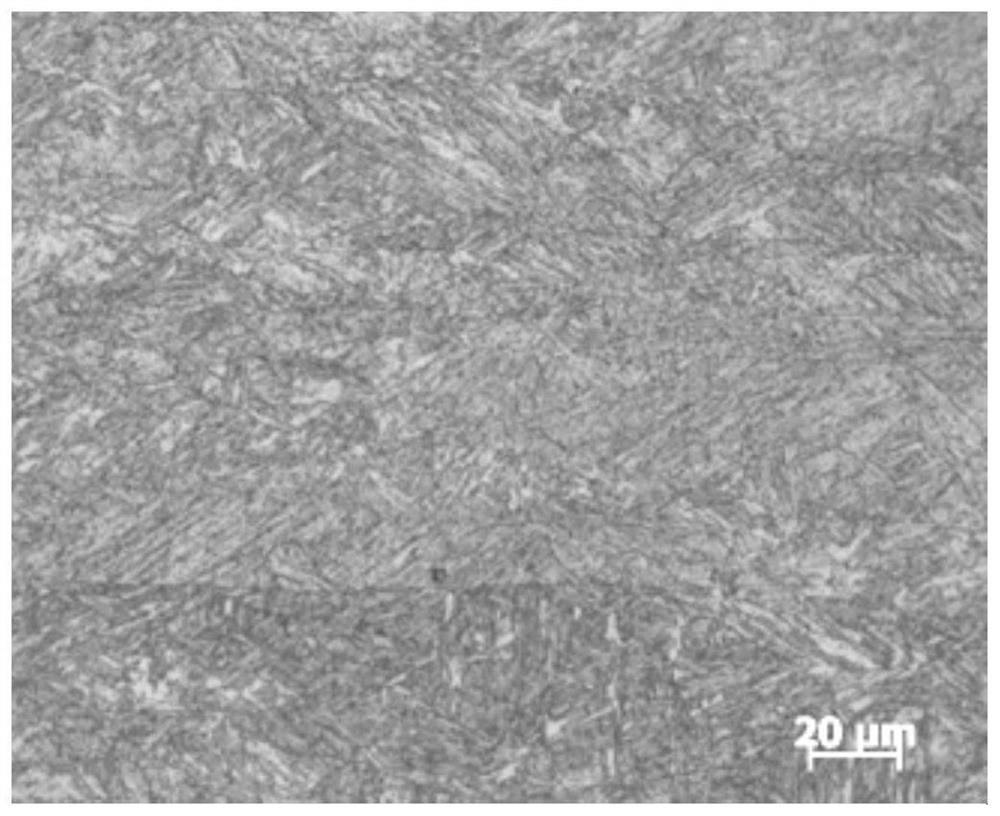

Image

Examples

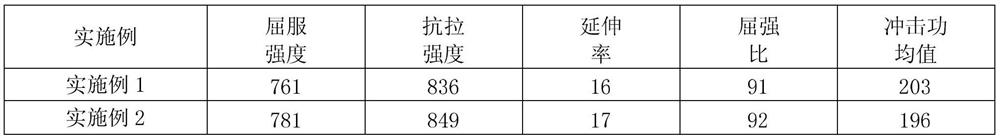

Embodiment 1

[0025] The N800CF steel for pumped-storage pressure steel pipes provided in this embodiment has the following chemical composition and mass percentage: C: 0.075%, Si: 0.15%, Mn: 1.28%, P: 0.011%, S: 0.0020%, Ti : 0.016%, Cr: 0.23%, Ni: 0.43%, Mo: 0.13%, Cu: 0.03%, Al: 0.009%, Mg: 0.0012%, N: 0.0031%, and the balance is Fe and inevitable impurities.

[0026] The manufacturing method includes the following steps:

[0027] S1, adopt liquid lime to apply stirring method to carry out molten iron desulfurization, and after desulfurization is finished, slag is sloughed into converter for blowing;

[0028] S2, converter blowing, nickel and molybdenum alloys are added to the converter together with the self-produced scrap steel, and the converter tapping adopts the strong deoxidization mode for deoxidation, the aluminum content after the furnace is 0.035%, and the sulfur content is 0.006%;

[0029] S3. After the molten steel reaches the LF furnace, adjust the ladle bottom to blow argo...

Embodiment 2

[0035] The N800CF steel for pumped-storage pressure steel pipes provided in this example is different from Example 1 in that its chemical composition and mass percentage are as follows: C: 0.093%, Si: 0.26%, Mn: 1.42%, P: 0.013 %, S: 0.0020%, Ti: 0.012%, Cr: 0.29%, Ni: 0.48%, Mo: 0.23%, Cu: 0.03%, Al: 0.013%, Mg: 0.0013%, N: 0.0027%, the balance is Fe and inevitable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com