12Cr2Mo1VR steel plate with low compression ratio and high flaw detection quality requirement for continuous casting billet forming and production process

A technology with low compression ratio and quality requirements, applied in the field of 12Cr2Mo1VR steel plate, can solve problems such as increased production costs, and achieve the effects of increased yield, increased density, and improved deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

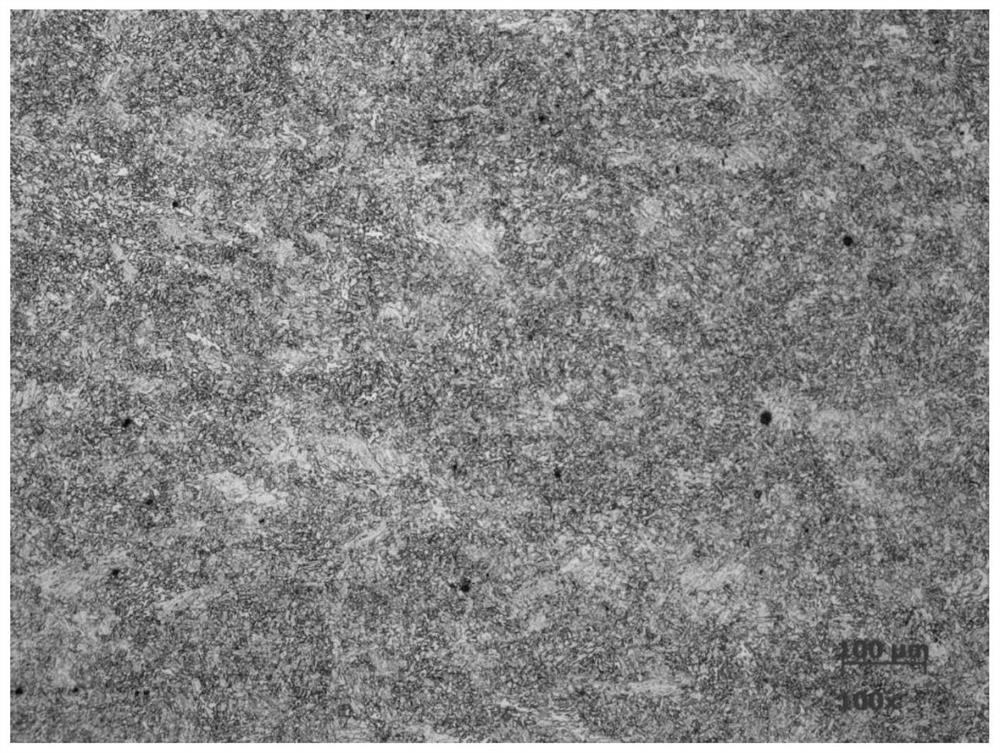

Image

Examples

Embodiment 1

[0033] In this embodiment, the thickness of the 12Cr2Mo1VR steel plate having a low compression ratio is 130 mm, using the process route: converter steel-LF refining-RH vacuum degassing-continuous casting-continuous casting heat-rolling-Clever-quenching Backlink - Flash - Fact - Test - Introduction.

[0034] The chemical composition of the steel sheet is: C: 0.09 ~ 0.17%, Si: ≤ 0.30%, Mn: 0.30 ~ 0.60%, P: ≤0.012%, S: ≤ 0.010%, CR: 2.00 ~ 2.50%, MO : 0.80 ~ 1.20%, V: 0.25 ~ 0.35%, Sb: ≤0.003%, SN: ≤ 0.010%, AS: ≤0.010%, margin is Fe and inevitable impurity elements.

[0035] The production process includes the following steps:

[0036] (1) Smelting process: The blast furnace iron water passes through iron water pretreatment, the converter is blown, ensured that the slag steel is added to the steel water, and the deoxidation is added to the steel water. Subsequently, the LF refining furnace is refined, strengthened with oxygen, effective refining time ≥ 30 min; molway The furnace en...

Embodiment 2

[0043] This embodiment relates to a 12Cr2MO1VR steel plate thickness of low compression than high flawless quality is 150 mm, and the process route is: converter steel-LF refining-RH vacuum degassing-continuous cast-continuous casting heat-rolling-Clever-quenching Backlink - Flash - Fact - Test - Introduction.

[0044] The chemical composition of the steel sheet is: C: 0.09 ~ 0.17%, Si: ≤ 0.30%, Mn: 0.30 ~ 0.60%, P: ≤0.012%, S: ≤ 0.010%, CR: 2.00 ~ 2.50%, MO : 0.80 ~ 1.20%, V: 0.25 ~ 0.35%, Sb: ≤0.003%, SN: ≤ 0.010%, AS: ≤0.010%, margin is Fe and inevitable impurity elements.

[0045] The production process includes the following steps:

[0046] (1) Smelting process: The blast furnace iron water passes through iron water pretreatment, the converter is blown, ensured that the slag steel is added to the steel water, and the deoxidation is added to the steel water. Subsequently, the LF refining furnace is refined, strengthened with oxygen, effective refining time ≥ 30 min; molway The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com