Waterproof and vibration-isolating microporous elastomer material for high-speed railway base and its structure

A microporous elastomer, waterproof and insulating technology, applied in building materials and application fields, can solve the problems of long-term waterproof and impermeability and insufficient vibration isolation performance, and achieve the effects of excellent support performance, few steps, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A railway roadbed waterproof and vibration-isolating microporous elastomer material and structure composited with waste rubber powder and polyurethane, wherein the composite waterproof and vibration-isolating microporous elastomer material of waste rubber powder and polyurethane is composed of the following preparation raw materials in parts by weight :

[0035] 30 parts of waste rubber powder with particle size of 80 meshes, 34-40 parts of polyurethane binder A component whose main component is polyol, 30-35 parts B component of polyurethane binder whose main component is polyisocyanate, 0.8 parts of polyurethane defoamer share.

[0036] in:

[0037] The source of the waste rubber powder with a particle size of 80 meshes is: the purchased grade is Guangzhou Aiqi Technology Co., Ltd. Fine Energy Rubber Powder, 80 meshes, in line with the GB T 19208-2008 standard;

[0038] The source of the component A of the polyurethane binder whose main component is polyol is: the p...

Embodiment approach

[0045] This embodiment includes the following steps:

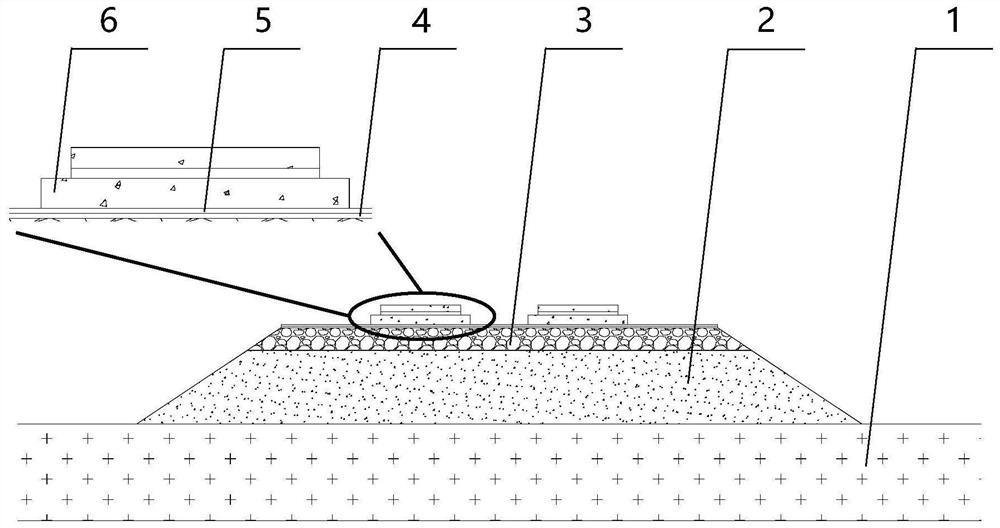

[0046](1) After building the soil foundation 1, the bottom layer 2 of the foundation bed and the surface layer 3 of the foundation bed, set a mold of a certain width and length according to the planning and construction design, and set the thickness of the waterproof and vibration isolation layer according to the service environment where the waterproof and vibration isolation layer is located. is 5 cm;

[0047] (2) According to the total construction amount and the above-mentioned raw material ratio, prepare and weigh the raw materials, place the waste rubber powder in an oven, stir and dry at 110 ° C for 2 hours;

[0048] (3) Weigh the polyurethane binders A and B and add them to the low-speed shearing mixer, control the rotation speed to be 60 rpm, shear and stir for 1 minute, then add the dry waste rubber powder, shear and stir for 1 minute, and then mix Add polyurethane defoamer, shear and stir for 0.5 minutes;

[0...

Embodiment 2

[0055] A waterproof and vibration isolation structure for high-speed railway base based on the composite waterproof and vibration isolation microporous elastomer material of waste rubber powder and polyurethane

[0056] This embodiment is roughly the same as the above-mentioned Embodiment 1, and the difference lies in this embodiment:

[0057] (1) According to the design, construction drawing design and the service environment where the waterproof vibration isolation layer is located, set the length, width and thickness of the waterproof vibration isolation layer prefabricated parts, and set the prefabricated mold;

[0058] (2) shearing and stirring to configure the mixture;

[0059] (3) pour the mixture into the prefabricated mould, let it stand for 1-2 days and then demould;

[0060] (4) After building the soil foundation 1, the bottom layer 2 of the foundation bed and the surface layer 3 of the foundation bed, install the prefabricated waterproof vibration isolation layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com