Fine silt collecting agent for achieving desliming through flotation and using method thereof

A collector and fine mud technology, applied in the field of collectors, can solve the problems of reducing the efficiency and quality of desliming, poor solubility, intolerant of hard water, etc., so as to improve the efficiency of desliming, enhance the ability of desliming, and reduce tension. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A fine mud collector for desliming by flotation, in parts by weight, the fine mud collector comprises sodium cetyl sulfonate: 1 part to 4 parts, stearic acid polyoxyethylene ether : 1 part-4 parts, sodium linoleate: 1 part-2 parts, petroleum sulfonate mixture: 1 part-2 parts.

[0025] Specifically, the petroleum sulfonate mixture mainly includes alkylarylsulfonates, arylalkylsulfonates, alkylsulfonates, and the like.

[0026] Specifically, the purity of the stearic acid polyoxyethylene ether is 90%.

[0027] Specifically, the purity of the sodium linoleate is 90%-95%.

[0028] Specifically, the purity of the sodium cetyl sulfonate is 28%-30%.

[0029] A method of using a fine mud collector comprising the steps of:

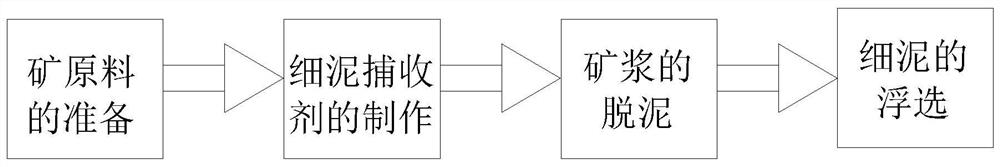

[0030] S1. Preparation of ore raw materials, first crush the ore raw materials with a crusher, then grind and pulverize the crushed ore raw materials for many times with a pulverizer, and finally add an appropriate amount of water to the crushed ore raw m...

Embodiment 2

[0039] A fine mud collector for desliming by flotation, in parts by weight, the fine mud collector comprises sodium cetyl sulfonate: 1 part to 4 parts, stearic acid polyoxyethylene ether : 1 part-4 parts, sodium linoleate: 1 part-2 parts, petroleum sulfonate mixture: 1 part-2 parts.

[0040] Specifically, the petroleum sulfonate mixture mainly includes alkylarylsulfonates, arylalkylsulfonates, alkylsulfonates, and the like.

[0041] Specifically, the purity of the stearic acid polyoxyethylene ether is 90%.

[0042] Specifically, the purity of the sodium linoleate is 90%-95%.

[0043] Specifically, the purity of the sodium cetyl sulfonate is 28%-30%.

[0044] A method of using a fine mud collector comprising the steps of:

[0045] S1. Preparation of ore raw materials, first crush the ore raw materials with a crusher, then grind and pulverize the crushed ore raw materials for many times with a pulverizer, and finally add an appropriate amount of water to the crushed ore raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com