A method and application of preparing two-dimensional covalent organic framework ultrathin nanosheet material composite film

A covalent organic framework and nanosheet technology, applied in the field of membrane separation, can solve problems such as difficulty in forming uniform membrane materials, inability to obtain high-quality gas separation membranes, and no breakthrough in the research of gas separation membrane materials. Effective size, improved gas separation performance, increased mechanical strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

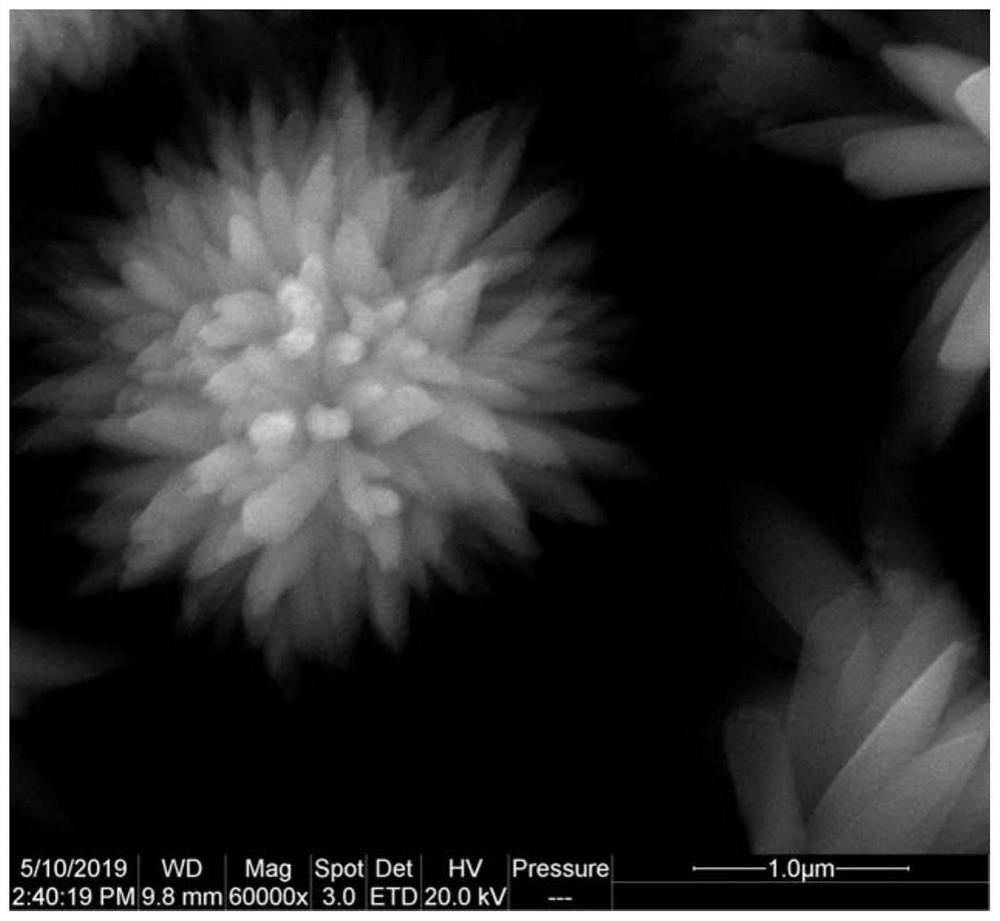

Image

Examples

Embodiment 1

[0060] The preparation of embodiment 1 TpPa-1

[0061] Add 31 mg of 1,3,5-trialdehydephloroglucinol (Tp) and 24 mg of p-phenylenediamine (Pa-1) powder into a Pyrex tube. 1.5 ml of 1,4-dioxane and 1,3,5-trimethylbenzene were added as solvents respectively. Add 0.5 ml of 3 mol per liter of acetic acid as a catalyst. The mixture was homogenized after sonication for 10 min. Then put the Pyrex glass tube into the liquid nitrogen bath to freeze. After the liquid in the tube solidifies, turn on the vacuum oil pump to pump air, and then take the sample tube out of the liquid nitrogen bath and wait for the liquid to melt. This freezing-pumping- The melting cycle needs to be performed three times. The vacuum-tight sample tube was placed in an oil bath at 120°C and heated for 72 hours to obtain a dark red powder. The powder was washed with tetrahydrofuran, methanol and acetone, extracted and washed with ethanol and dichloromethane, and dried under vacuum at 120° C. for 12 hours to ob...

Embodiment 2

[0063] The preparation of embodiment 2 TpPa-2

[0064] Add 31 mg of 1,3,5-trialdehydephloroglucinol (Tp) and 30 mg of 2,5-dimethyl-1,4-phenylenediamine (Pa -2) Powder. 1.5 ml of 1,4-dioxane and 1,3,5-trimethylbenzene were added as solvents respectively. Add 0.5 ml of 3 mol per liter of acetic acid as a catalyst. The mixture was homogenized after sonication for 10 min. Then put the Pyrex glass tube into the liquid nitrogen bath to freeze. After the liquid in the tube solidifies, turn on the vacuum oil pump to pump air, and then take the sample tube out of the liquid nitrogen bath and wait for the liquid to melt. This freezing-pumping- The melting cycle needs to be performed three times. The vacuum-tight sample tube was placed in an oil bath at 120°C and heated for 72 hours to obtain a dark red powder. The powder was washed with tetrahydrofuran, methanol and acetone, extracted and washed with ethanol and dichloromethane, and dried under vacuum at 120° C. for 12 hours to obt...

Embodiment 3

[0066] Example 3 NO 2 - Preparation of TpPa

[0067] Add 31 mg of 1,3,5-trialdehyde phloroglucinol (Tp) and 34.5 mg of o-nitro-p-phenylenediamine (NO 2-Pa) powder. 1.5 ml of 1,4-dioxane and 1,3,5-trimethylbenzene were added as solvents respectively. Add 0.5 ml of 3 mol per liter of acetic acid as a catalyst. The mixture was homogenized after sonication for 10 min. Then put the Pyrex glass tube into the liquid nitrogen bath to freeze. After the liquid in the tube solidifies, turn on the vacuum oil pump to pump air, and then take the sample tube out of the liquid nitrogen bath and wait for the liquid to melt. This freezing-pumping- The melting cycle needs to be performed three times. The vacuum-tight sample tube was placed in an oil bath at 120°C and heated for 72 hours to obtain a dark red powder. The powder was washed with tetrahydrofuran, methanol and acetone, extracted and washed with ethanol and dichloromethane, and dried under vacuum at 120°C for 12 hours to obtain N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com