Electrocatalyst with sandwich structure, and preparation method and application thereof

An electrocatalyst and sandwich technology, applied in structural parts, fuel cell half-cells and secondary battery-type half-cells, circuits, etc., can solve the problems of severe agglomeration of nanoparticles and degradation of electrochemical performance, and achieve high internal Effects of activity, high current density, and low overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

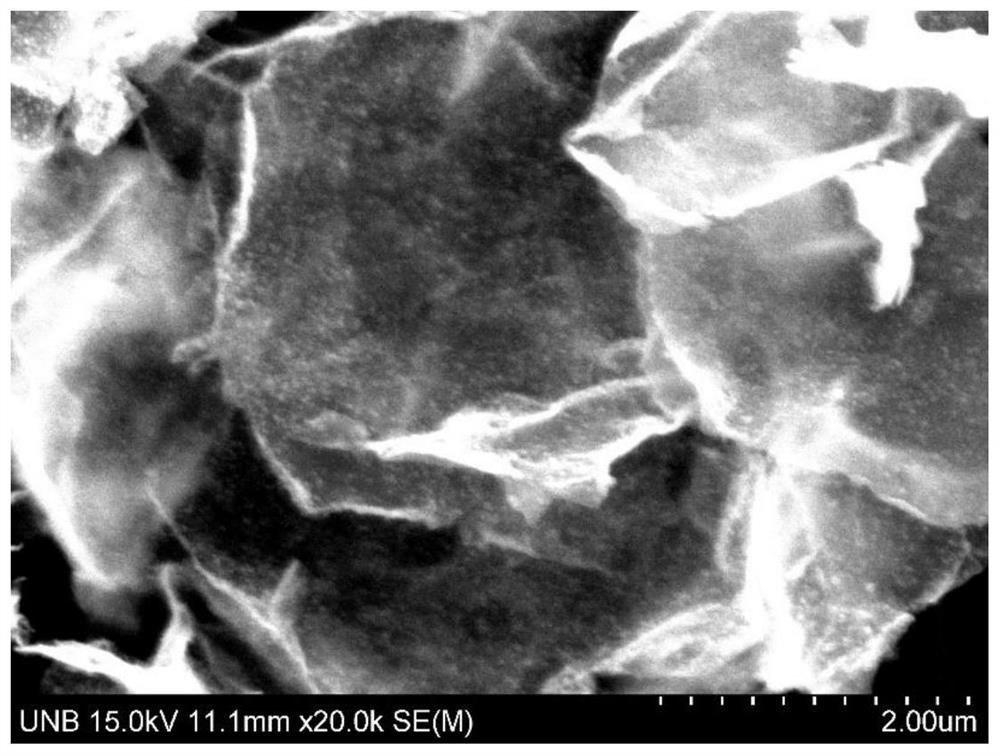

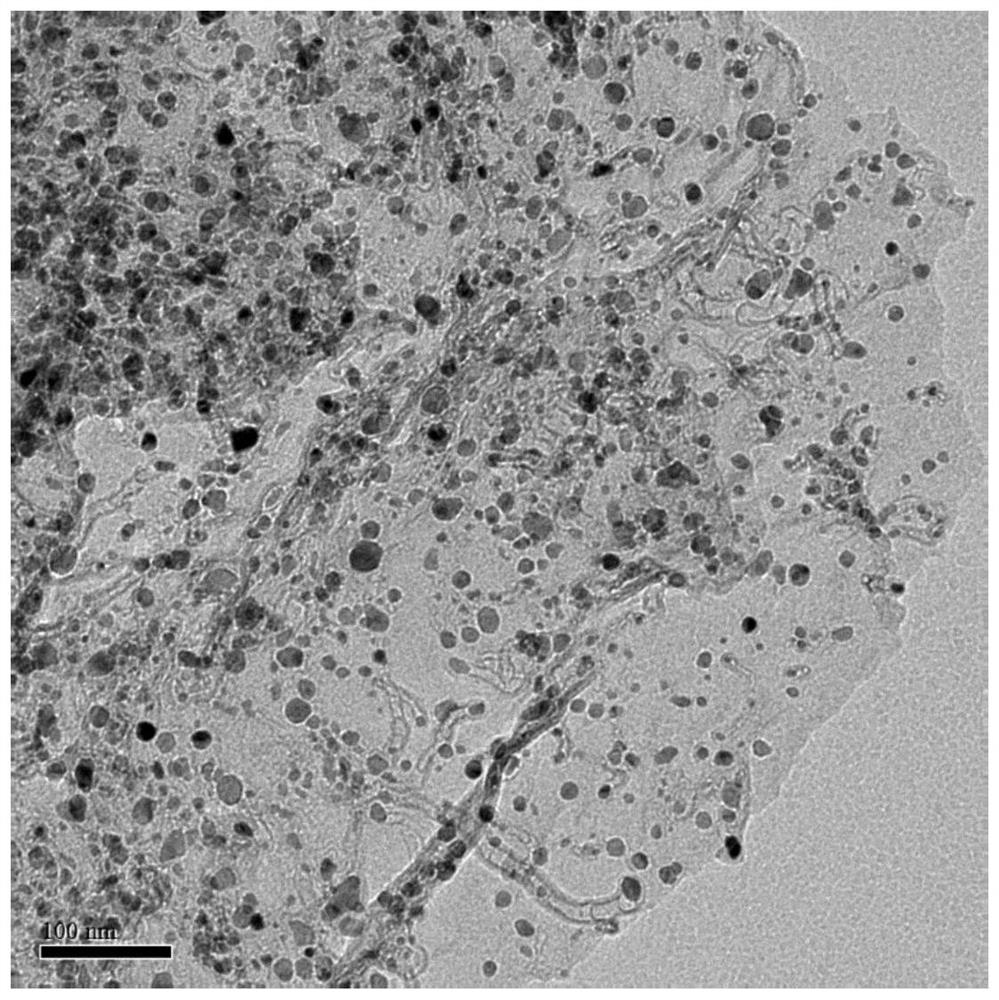

[0028] This embodiment provides a method for preparing an electrocatalyst with a sandwich structure, which is obtained through the following steps:

[0029] Step 1): Add 3g of graphite powder to 120ml of concentrated sulfuric acid, slowly add 15g of KMnO under stirring 4 , transferred to a 35°C oil bath and stirred for 2 hours, then slowly added 250ml of deionized water, reacted for 1.5 hours and then added H 2 o 2 , after cooling to room temperature, suction filtration and washing, dialysis, freeze-drying and storage.

[0030] Step 2): get 0.5g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in DMF, then add 0.1 g of graphene oxide from step 1 into it, stir and ultrasonically 1 h to form a uniformly dispersed mixed solution.

[0031] Step 3): Dissolve 0.5g of adenine in DMF under heating conditions (specific temperature 155°C), add the mixed solution obtained in step 1 into it, stir for 4 hours, and after cooling to room temperature, carry out centrifugal wa...

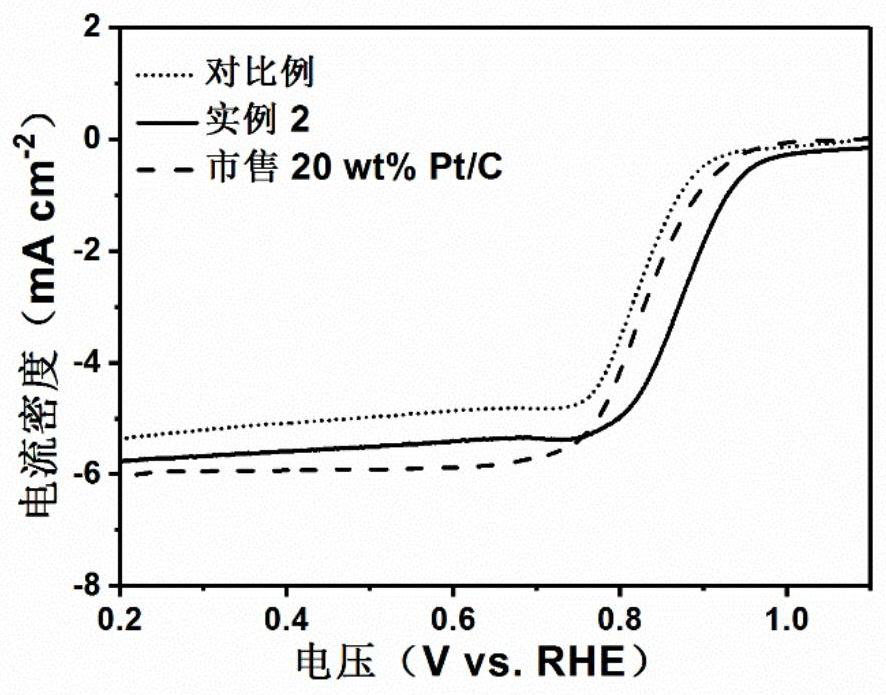

Embodiment 2

[0034] This embodiment provides a method for preparing an electrocatalyst with a sandwich structure, which is obtained through the following steps:

[0035] Step 1): Add 3g of graphite powder to 120ml of concentrated sulfuric acid, slowly add 15g of KMnO under stirring 4 , transferred to a 35°C oil bath and stirred for 2 hours, then slowly added 250ml of deionized water, reacted for 1.5 hours and then added H 2 o 2 , after cooling to room temperature, suction filtration and washing, dialysis, freeze-drying and storage.

[0036] Step 2): get 0.5g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in DMF, then add 0.2 g of graphene oxide from step 1 into it, stir and ultrasonically 1 h to form a uniformly dispersed mixed solution.

[0037] Step 3): Dissolve 0.5g of adenine in DMF under heating conditions (155°C), add the mixed solution obtained in Step 1, stir for 4 hours, and after cooling to room temperature, carry out centrifugation to collect the precipitate, ...

Embodiment 3

[0040] This embodiment provides a method for preparing an electrocatalyst with a sandwich structure, which is obtained through the following steps:

[0041] Step 1): Add 3g of graphite powder to 120ml of concentrated sulfuric acid, slowly add 15g of KMnO under stirring 4 , transferred to a 35°C oil bath and stirred for 2 hours, then slowly added 250ml of deionized water, reacted for 1.5 hours and then added H 2 o 2 , after cooling to room temperature, suction filtration and washing, dialysis, freeze-drying and storage.

[0042] Step 2): get 0.5g of cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) Dissolve in DMF, then add 0.3 g of graphene oxide from step 1 into it, stir and ultrasonically 1 h, to form a uniformly dispersed mixed solution.

[0043]Step 3): Dissolve 0.5g of adenine in DMF under heating conditions (155°C), add the mixed solution obtained in Step 1, stir for 4 hours, and after cooling to room temperature, carry out centrifugation to collect the precipitate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com