Heat sink structure design method based on contour extraction

A technology of contour extraction and structural design, applied in computer-aided design, calculation, instrument, etc., can solve the problems of unsatisfactory heat dissipation performance of MCFHS, poor flow and cooling capacity in wake area, pressure loss, etc., and achieve uniform temperature distribution on the bottom surface, Good convection heat transfer performance and small overall thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following will clearly and completely describe the technical solutions and specific implementation methods of the present invention with reference to the accompanying drawings in the present invention.

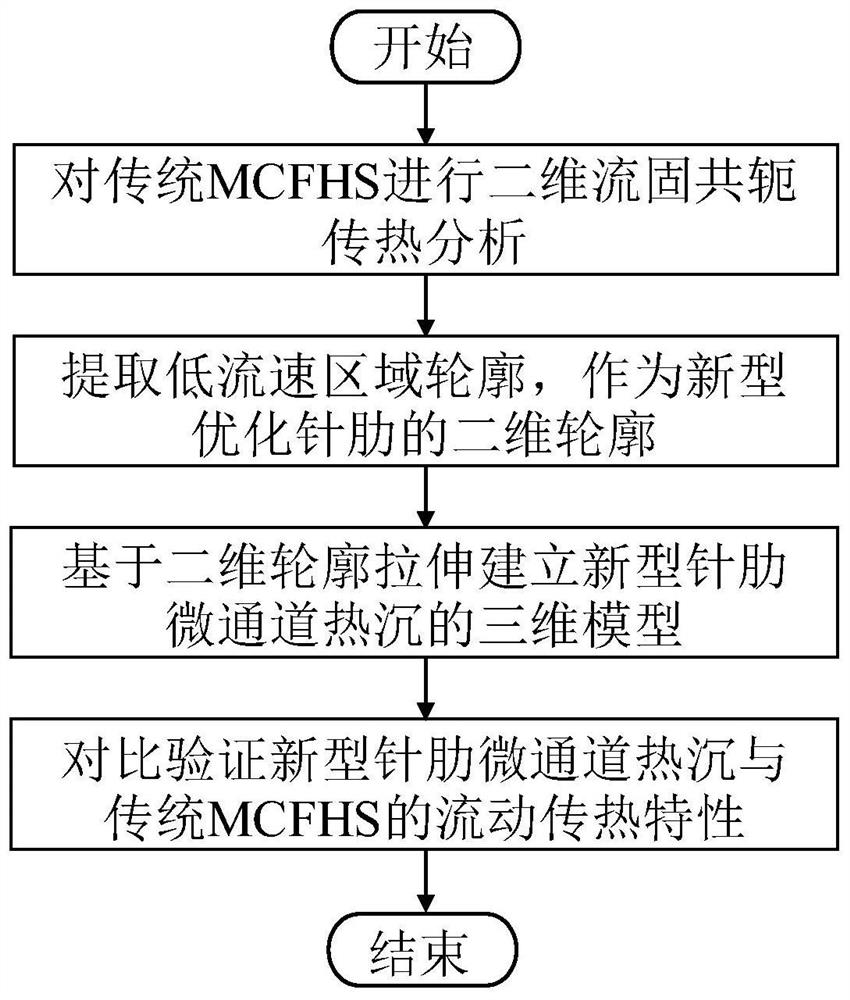

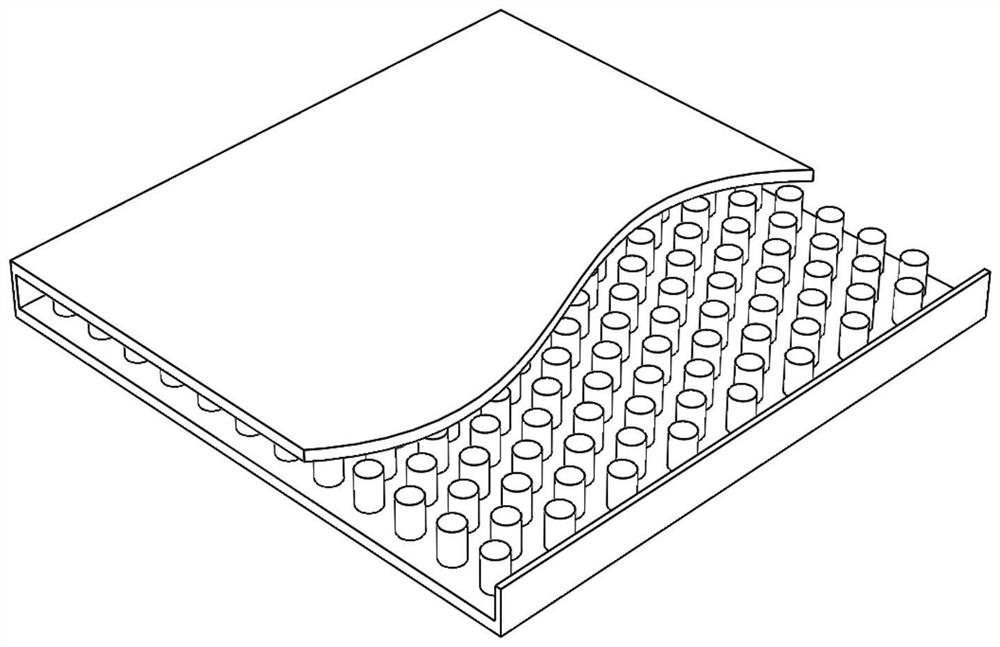

[0033] Such as figure 2 Shown is the optimization object in this example, that is, the traditional MCFHS, its overall size is 25mm*25mm*2.5mm, the solid substrate material used is copper, and the cooling liquid is water. According to the heat sink structure design method based on contour extraction designed in the present invention, its optimal design process includes the following steps:

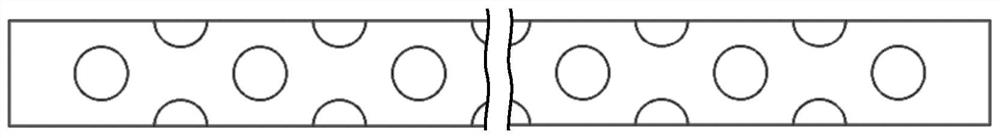

[0034] S1: Through the fluid-solid conjugate two-dimensional heat transfer model pair figure 2 Analysis of flow characteristics and heat transfer characteristics in traditional MCFHS;

[0035] S2: Extract the contour of the low-velocity area around the cylindrical needle fin as the 2D contour of the new needle fin;

[0036] S3: Based on the obtained 2D profile of the new pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com