Novel preparation method of high-temperature-resistant gelatin film and product

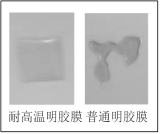

A technology of gelatin film and high temperature resistance, applied in the field of food packaging, can solve the problems of inability to withstand boiling water bath and high temperature sterilization, disintegration of the triple helix structure of gelatin, limiting the practical application of gelatin film, etc. , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prepare high temperature resistant gelatin films.

[0032] (1) Swelling: Dissolve 5 g of type B gelatin in 90 mL of pure water and swell for 2 h until no powdery particles exist, and all gelatin appears transparent.

[0033] (2) Dissolution: The swollen gelatin was dissolved in a water bath at 60°C for 30 minutes until it was completely dissolved, and it was in the form of a clear and uniform aqueous solution.

[0034] (3) Transglutaminase blending and defoaming: Dissolve 0.1 g of transglutaminase in 10 mL of pure water, add the gelatin solution to be dissolved after cooling to 40 °C, and mix well to provide a total valence interaction reactive groups, followed by ultrasonic treatment at 40 °C for 10 min to obtain a homogeneous cross-linked gelatin solution without bubbles.

[0035] (4) Film pouring solution: Pour 30 mL of film forming solution into a 15×15 cm polytetrafluoroethylene dish and evenly spread it to shape.

[0036] (5) Insulation treatment: Place the samp...

Embodiment 2

[0041] Prepare high temperature resistant gelatin films.

[0042] (1) Swelling: Dissolve 10 g of type B gelatin in 90 mL of pure water and swell for 2 h until no powdery particles exist, and all the gelatin appears transparent.

[0043] (2) Dissolution: The swollen gelatin was dissolved in a water bath at 60°C for 30 minutes until it was completely dissolved, and it was in the form of a clear and uniform aqueous solution.

[0044](3) Transglutaminase blending and defoaming: Dissolve 0.1 g of transglutaminase in 10 mL of pure water, add the gelatin solution to be dissolved after cooling to 40 °C, and mix well to provide a total valence interaction reactive groups, followed by ultrasonic treatment at 40 °C for 10 min to obtain a homogeneous cross-linked gelatin solution without bubbles.

[0045] (4) Film pouring solution: Pour 30 mL of film forming solution into a 15×15 cm polytetrafluoroethylene dish and evenly spread it to shape.

[0046] (5) Insulation treatment: Place the ...

Embodiment 3

[0051] Prepare high temperature resistant gelatin films.

[0052] (1) Swelling: Dissolve 15 g of B-type gelatin in 90 mL of pure water and swell for 2 h until no powdery particles exist, and all gelatin appears transparent.

[0053] (2) Dissolution: The swollen gelatin was dissolved in a water bath at 60°C for 30 minutes until it was completely dissolved, and it was in the form of a clear and uniform aqueous solution.

[0054] (3) Transglutaminase blending and defoaming: Dissolve 0.1 g of transglutaminase in 10 mL of pure water, add the gelatin solution to be dissolved after cooling to 40 °C, and mix well to provide a total valence interaction reactive groups, followed by ultrasonic treatment at 40 °C for 10 min to obtain a homogeneous cross-linked gelatin solution without bubbles.

[0055] (4) Film pouring solution: Pour 30 mL of film forming solution into a 15×15 cm polytetrafluoroethylene dish and evenly spread it to shape.

[0056] (5) Insulation treatment: Place the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal degradation temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com