Organosilicon modified acrylic acid secondary dispersion and preparation method thereof

A secondary dispersion and silicone technology, applied in the field of modified resins, can solve the problems of environment, worker hazard, difficult to increase grafting rate, unfavorable long-term development, etc., to avoid air pollution and less oil floating. , the effect of improving the grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

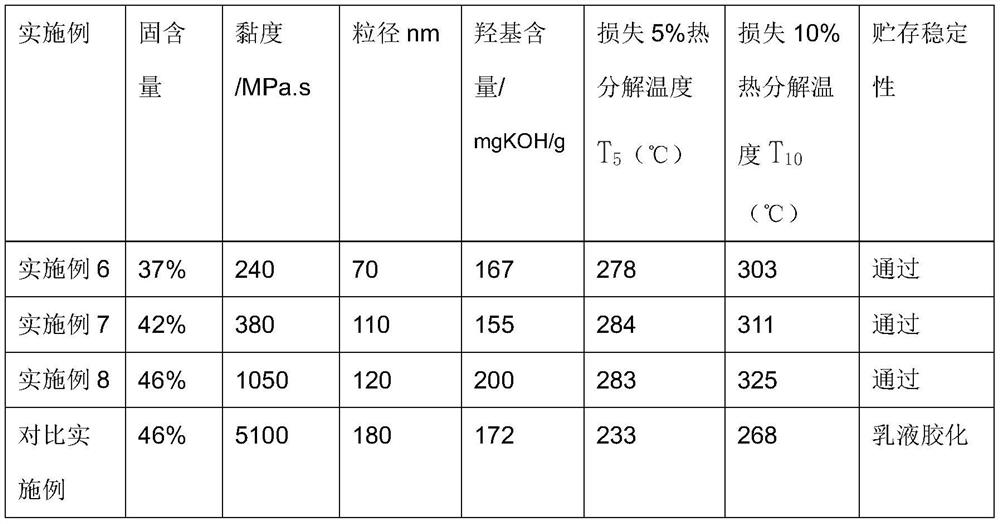

Examples

Embodiment 1

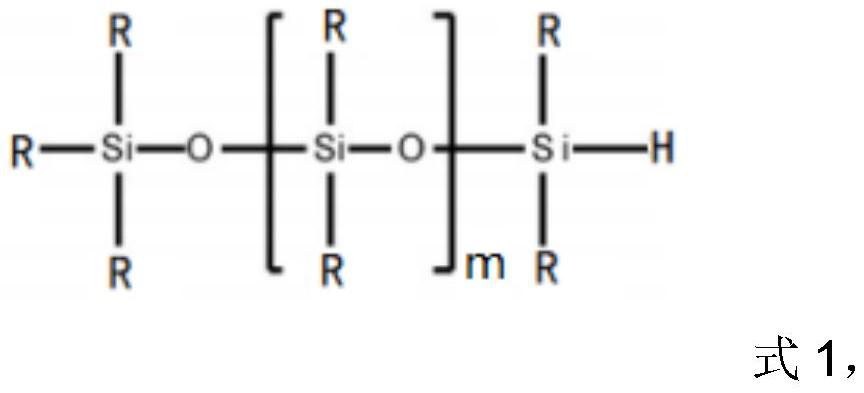

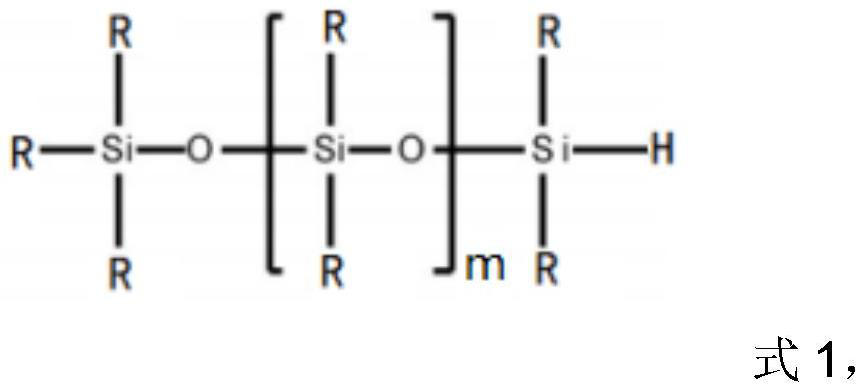

[0065] Under the condition of nitrogen protection, mix 12.7g of allyl methacrylate, 100g of silicone oil containing a silicon hydrogen group at one end, 0.006g of polymerization inhibitor p-hydroxyanisole and 0.6g of 5000ppm Castel platinum catalyst, at 40°C After reacting for 10 hours and then distilling under reduced pressure, the organosilicon modified monomer was obtained with a yield of 99%. After testing, the viscosity was 13mPa.s, the number average molecular weight was 1130, the vinyl content was 2.3%, and the hydrogen content was 0. ;

[0066] The preparation method of the silicone oil containing a silicon hydrogen group at one end is:

[0067] Add 300g of octamethylcyclotetrasiloxane to a 1L three-necked flask, add 5.4g of concentrated sulfuric acid and 600g of toluene and slowly raise the temperature to 75°C, react for 3 hours, add 45g of potassium trimethylsiliconate and 270g of THF and raise the temperature to 80°C for 10 hours , cooled to room temperature, 33g o...

Embodiment 2

[0069] Under the condition of nitrogen protection, mix 11.3g of allyl acrylate, 100g of silicone oil containing a silicon hydrogen group at one end, 0.006g of polymerization inhibitor p-hydroxyanisole and 0.7g of 5000ppm Castel platinum catalyst, and react at 40°C for 8h. After vacuum distillation, the silicone modified monomer was obtained with a yield of 99%, a viscosity of 12 mPa.s, a number average molecular weight of 1112, a vinyl content of 2.4%, and a hydrogen content of 0;

[0070] The preparation method of the silicone oil containing a silicon hydrogen group at one end is the same as in Example 1.

Embodiment 3

[0072] Under the condition of nitrogen protection, mix 4.7g of allyl methacrylate, 100g of silicone oil containing a silicon hydrogen group at one end, 0.25g of polymerization inhibitor p-hydroxyanisole and 0.27g of 5000ppm Castel platinum catalyst, and react at 60°C 8h, and then distilled under reduced pressure to obtain a silicone-modified monomer with a yield of 99%, a viscosity of 30mPa.s, a number average molecular weight of 2830, a vinyl content of 0.91%, and a hydrogen content of 0 ;

[0073] The preparation method of the silicone oil containing a silicon hydrogen group at one end is:

[0074]Add 300g of octamethylcyclotetrasiloxane to a 1L three-necked flask, add 0.9g of trifluoromethanesulfonic acid and 90g of toluene and slowly raise the temperature to 75°C, add 15g of potassium trimethylsiliconate and 45g of THF and raise the temperature to 80°C after 3 hours of reaction React at ℃ for 10 hours, cool to room temperature, add 11g of dimethyl monochlorosilane dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com