High-performance metallic bond, grinding wheel comprising high-performance metallic bond and preparation method of grinding wheel

A metal bond and high-performance technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problem of the decrease of metal bond's holding force on diamond, the decrease of thermal conductivity of diamond grinding wheel, and the easy falling off of diamond abrasive grains and other problems, to achieve the effect of uniform hardness, good sharpness, and good grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

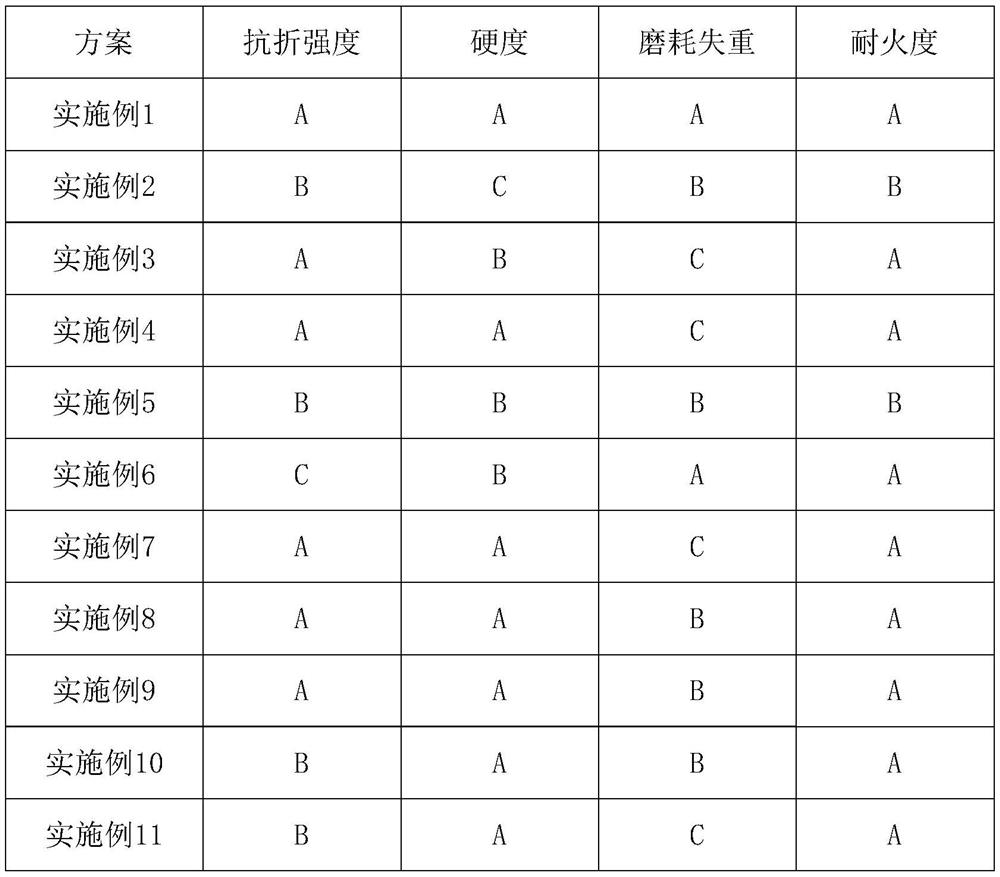

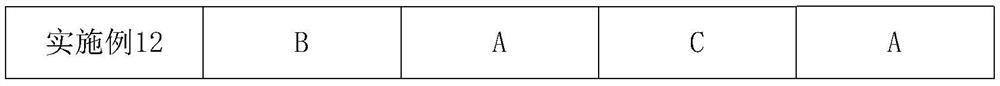

Examples

preparation example Construction

[0031] Another aspect of the present invention provides, a kind of grinding wheel, described grinding wheel comprises high-performance metal bonding agent, and the preparation method of described grinding wheel comprises the following steps:

[0032] Step 1: Mix the metal bond and diamond with a high-speed mixer for 12-24 hours;

[0033] Step 2: Using a mold, sintering the mixture of metal powder and diamond abrasive grains at a temperature of 500-1500°C and a pressure of 1-20T, and then demoulding to obtain a grinding wheel containing a high-performance metal bond.

[0034] In some preferred technical solutions, the mass ratio of the diamond to the metal bond in Step 1 is 1:(4-6).

[0035] The holding force of the metal bond of the present invention on diamond abrasive grains mainly includes three types: van der Waals force, metallurgical force between bond and diamond, and mechanical wrapping effect of bond on diamond. In the metal bond diamond grinding wheel, the mechanica...

Embodiment 1

[0044] This embodiment provides on the one hand a high-performance metal bond, the raw materials for the preparation of the metal bond in parts by mass include: 60 parts of copper-tin alloy powder, 10 parts of nickel powder, 15 parts of cobalt powder, silicon dioxide powder 10 parts, 10 parts of iron powder, 10 parts of silver powder, and 3 parts of aluminum oxide powder; on the other hand, this embodiment provides a preparation method of a grinding wheel comprising the high-performance metal bond, the preparation method comprising the following steps:

[0045] Step 1: Mix the metal bond with the diamond for 24 hours using a high-speed mixer;

[0046] Step 2: Using a mold, sintering the mixture of the metal powder and the diamond abrasive grains under the conditions of a temperature of 780° C. and a pressure of 100 T to prepare a grinding wheel containing a high-performance metal bond.

[0047] The mass ratio of copper to tin in the copper-tin alloy powder is 12:1;

[0048] T...

Embodiment 2

[0053] This embodiment provides, on the one hand, a high-performance metal bond. The raw materials for the preparation of the metal bond include: 60 parts of copper-tin alloy powder, 10 parts of nickel powder, 10 parts of silicon dioxide powder, iron powder 10 parts, 10 parts of silver powder, 3 parts of aluminum oxide powder; on the other hand, this embodiment provides a preparation method of a grinding wheel comprising the high-performance metal bond, the preparation method comprising the following steps:

[0054] Step 1: Mix the metal bond with the diamond for 24 hours using a high-speed mixer;

[0055] Step 2: Using a mold, sintering the mixture of the metal powder and the diamond abrasive grains under the conditions of a temperature of 780° C. and a pressure of 100 T to prepare a grinding wheel containing a high-performance metal bond.

[0056] The mass ratio of copper to tin in the copper-tin alloy powder is 12:1;

[0057] The average particle size of the metal binder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com