Laser welding system, laser welding control method and device and storage medium

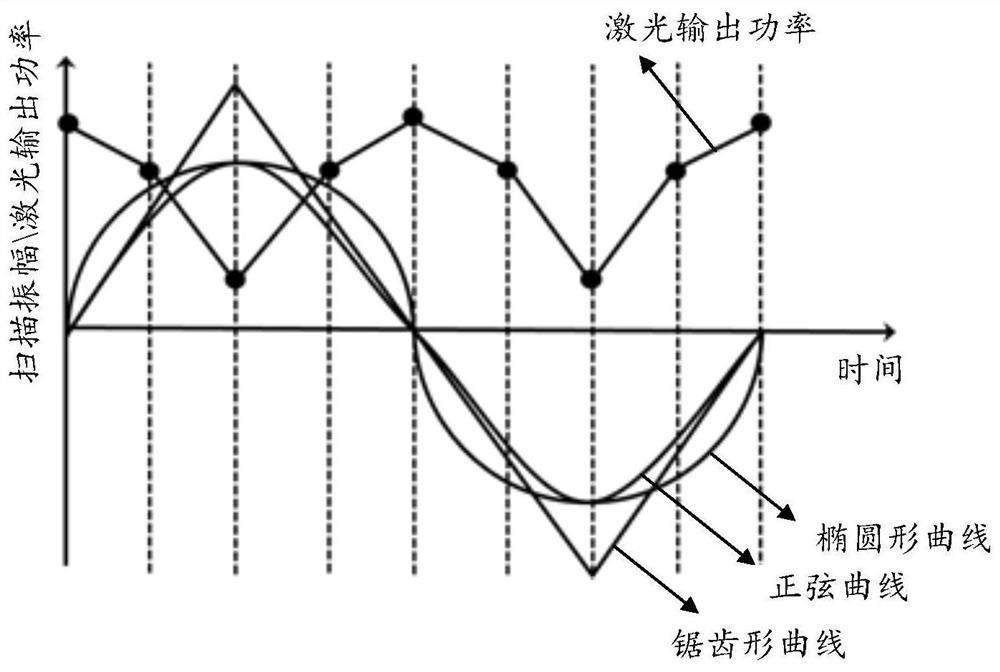

A laser welding and laser technology, used in laser welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of inflexible laser energy distribution, pores, lack of fusion, etc., to reduce energy, high-quality welding, and improve flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The specific implementation manners of the present application will be further described in detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present application, but not to limit the scope of the present application.

[0066] First, some terms involved in this application are introduced.

[0067] Laser Scanner Welding (LSW): The laser beam is incident on the X and Y axis mirrors of the scanning galvanometer, and the angle of the mirror is controlled by the computer to achieve arbitrary deflection of the laser beam, so that the laser beam with a certain power density The laser is focused on different positions on the surface of the workpiece to realize the welding function.

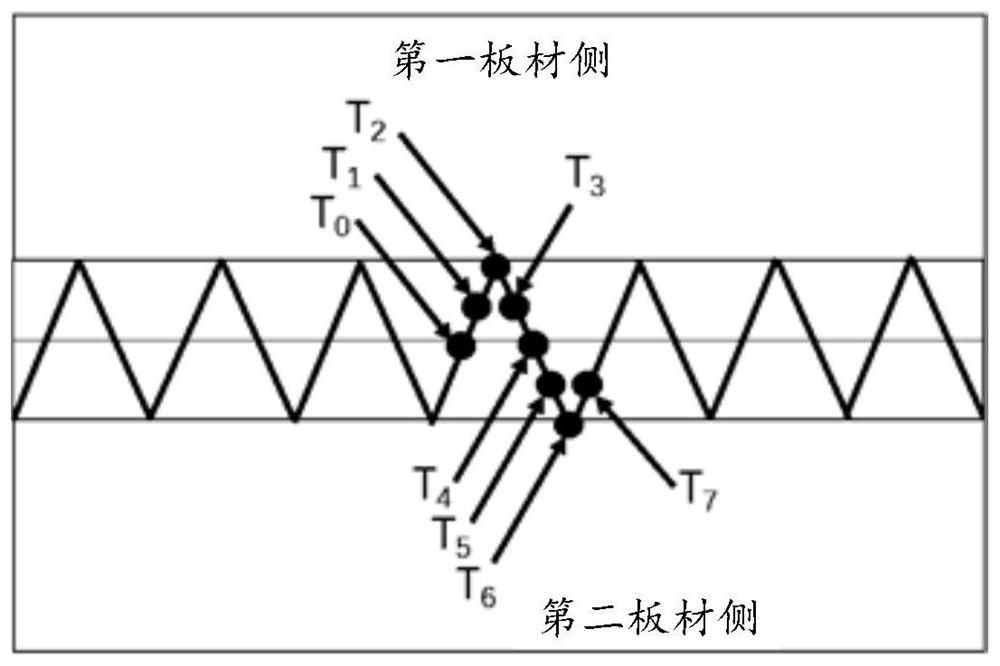

[0068] Negative Defocus: The focal plane is below the workpiece for negative defocus.

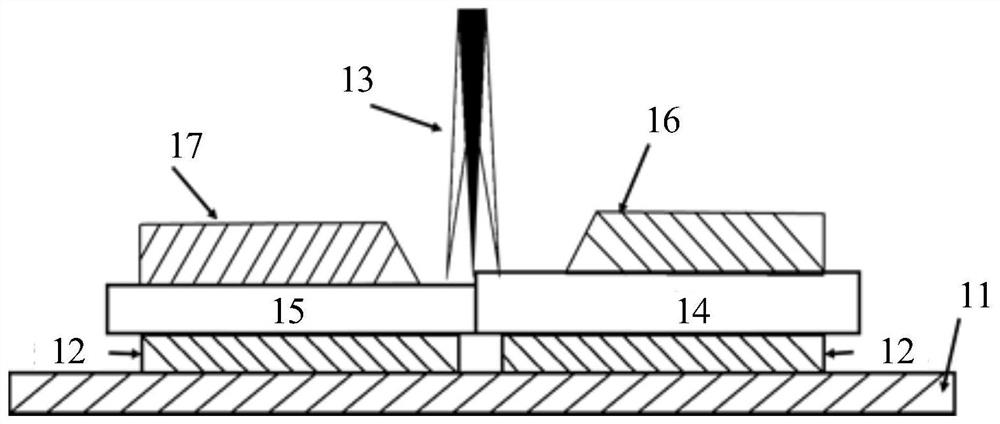

[0069] The laser welding system provided by this application will be described below. Optionally, the application scenario of the laser welding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com