Argon arc preheating wire welding method

A technology of welding wire and argon arc, applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc., can solve heating and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific implementation mode 1: In this implementation mode, the welding wire is preheated in this way: the arc protected by argon gas is used as the heating source, and one end of the TIG power supply with controllable output current is connected to the gun, and the other end is connected to the wire feeder to feed At the wire nozzle, an arc is ignited to heat the welding wire.

specific Embodiment approach 2

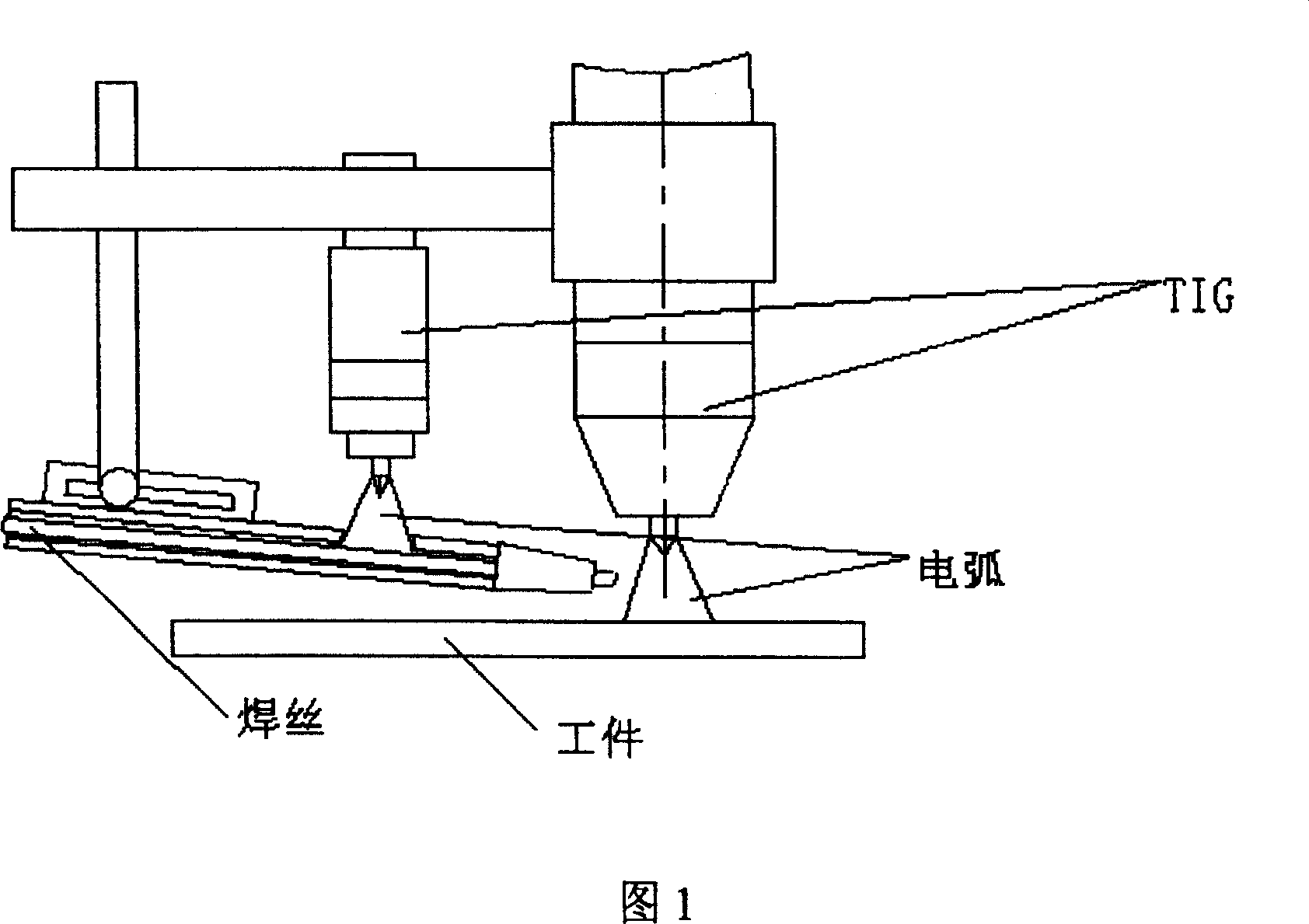

[0006] Embodiment 2: In this embodiment, the method for preheating the welding wire will be described in detail with reference to FIG. 1 . This embodiment adopts the arc of TIG protected by argon gas as the heating heat source. As shown in Figure 1, two TIG welding torches are installed on the support frame. The right torch in the figure is used to weld the workpiece, and the middle torch passes through the small window on the wire feeder The ignition arc heats the welding wire to form the argon arc hot wire TIG technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com