A kind of red light phosphor material and preparation method thereof

A red light phosphor and raw material technology, applied in the direction of luminescent materials, chemical instruments and methods, climate sustainability, etc., can solve the problems of low color rendering index, high color temperature, and poor color rendering of white light LEDs, and achieve redness Excellent light performance, stable chemical properties, and the effect of improving light and color performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

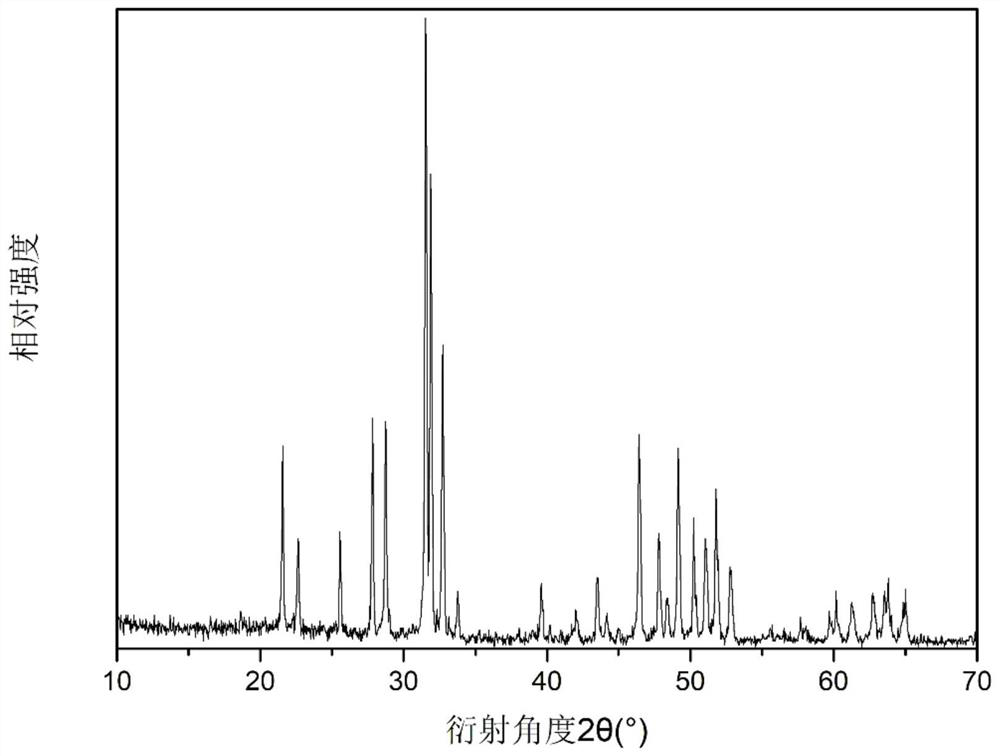

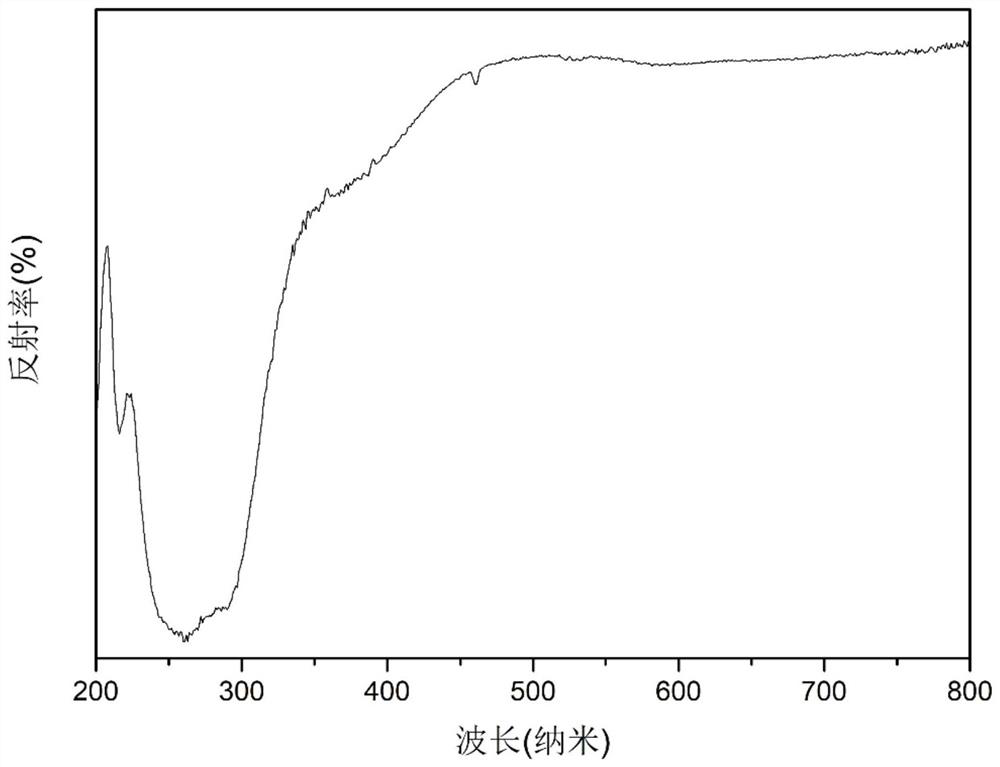

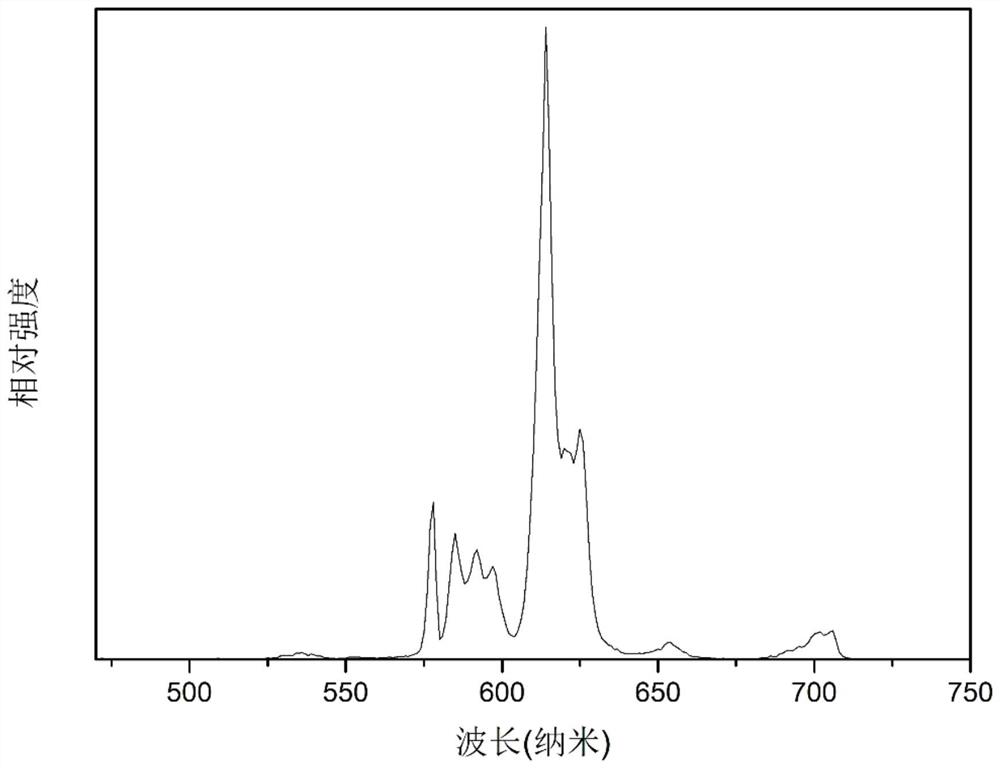

Embodiment 1

[0027] Weigh 2.0539g of SrCO with an analytical balance 3 , 5.3486g of Y 2 O 3 , 0.0842g of Eu 2 O 3 , 0.4429g of H 3 BO 3 , 2.0539g of SiO 2 and 0.5570g of NH 4F Pour it into the agate mortar and mix, add an appropriate amount of anhydrous ethanol, fully grind it evenly, the grinding time is 70 minutes, pour the powder mixture obtained after fully grinding into a corundum ceramic crucible, and place the corundum crucible containing the powder mixture in a muffle Pre-sintering in a furnace, heating to 900° C. at a rate of 100° C. / h, holding for 5 hours, and cooling to room temperature with the furnace to obtain pre-sintered powder. The pre-sintered powder was ground for 40 minutes, and then placed in the corundum crucible again. The corundum crucible containing the pre-sintered powder was placed in a muffle furnace for high-temperature solid-phase reaction, and the temperature was raised to 1350 ° C at a rate of 250 ° C / h, and the temperature was maintained for 12 h. T...

Embodiment 2

[0029] Weigh 2.0861g of SrCO with an analytical balance 3 , 5.5282g of Y 2 O 3 , 0.0871g of Eu 2 O 3 , 0.4368g of H 3 BO 3 , 2.1229g of SiO 2 , 0.4950g of CaF 2 and 0.0523g of NH 4 Pour F into an agate mortar and mix, add an appropriate amount of anhydrous ethanol, fully grind evenly, and grind for 1 hour. The powder mixture obtained after fully grinding is poured into a corundum crucible, and the corundum crucible containing the powder mixture is placed in a muffle Pre-sintering in the furnace, heating to 900° C. at a rate of 90° C. / h, holding for 6 hours, and cooling to room temperature with the furnace to obtain pre-sintered powder. The pre-sintered powder was ground for 40 minutes, and then placed in a corundum crucible again. The corundum crucible containing the pre-sintered powder was placed in a muffle furnace for high-temperature solid-phase reaction, and the temperature was raised to 1450° C. at a rate of 200° C. / h. The furnace was cooled to room temperature,...

Embodiment 3

[0031] Weigh 1.0794g of SrCO with an analytical balance 3 , 5.7206g of Y 2 O 3 , 0.0901g of Eu 2 O 3 , 0.4521g of H 3 BO 3 , 2.9165g of SiO 2 , 0.8200g of CaO and 0.5957g of NH 4 F is poured into the agate mortar and mixed, and an appropriate amount of anhydrous ethanol is added, and the grinding time is 1 hour. The powder mixture obtained after sufficient grinding is poured into the corundum crucible, and the corundum crucible containing the powder mixture is placed in the muffle furnace. Pre-sintered in medium, heated to 800° C. at a rate of 100° C. / h, kept for 6 hours, and cooled to room temperature with the furnace to obtain pre-sintered powder. The pre-sintered powder was ground for 45 minutes, and then placed in a corundum crucible again. The corundum crucible containing the pre-sintered powder was placed in a muffle furnace for high-temperature solid-phase reaction, and the temperature was raised to 1400 ° C at a rate of 300 ° C / h, and the temperature was maintai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com