Red phosphor, preparation method of red phosphor and light-emitting device

A technology of red phosphor and phosphor layer, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc. It can solve the problems of no solution, poor light and color properties of fluoride red phosphor, and difficult to effectively adjust the component structure, etc. problems, to achieve the effect of increasing the display color gamut and improving light and color performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

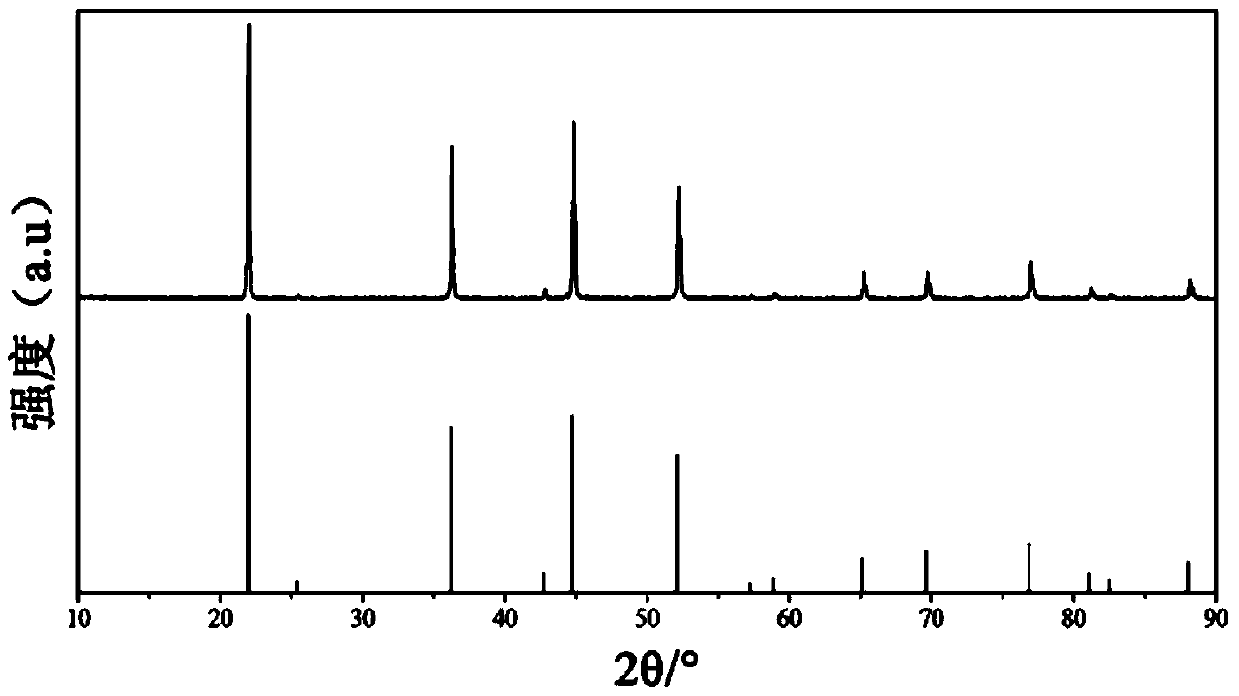

[0039] At the same time, the present invention also provides a preparation method of red fluorescent powder, the preparation method comprising the following steps: weighing A and A respectively according to the stoichiometric ratio 2 MnF 6 、A 2 [XF 6 ], D-containing salt and Al-containing salt, wherein, A is selected from Li + 、Na + and K + Any one or more of, D is selected from Ba 2+ 、Sr 2+ , Ca 2+ and Mg 2+ Any one or more of, X is selected from Si 4+ 、 Ge 4+ and Ti 4+ Any one or more of them; the A 2 MnF 6 Dissolved in the first HF solution to obtain the first solution, A 2 [XF 6 ] is dissolved in a second HF solution to obtain a second solution, the D-containing salt is dissolved in a third HF solution to obtain a third solution, and the Al-containing salt is dissolved in a fourth HF solution to obtain a fourth solution; The first solution, the second solution, the third solution and the fourth solution are added dropwise to react at the same time to obtain ...

Embodiment 1

[0060] According to K 1.95 Sr 0.05 (Si 0.77 al 0.05 ) F 6 :0.18Mn 4+ The stoichiometric ratio was weighed respectively potassium fluoromanganate, K 2 SiF 6 , AlF 3 and SrF 2 and other raw materials were dissolved in 35wt% HF solution to obtain the hydrofluoric acid solution of potassium fluoromanganate and K 2 SiF 6 , AlF 3 and SrF 2 Two kinds of mixed solutions of hydrofluoric acid solution, the two mixed solutions are evenly added dropwise at 80°C in proportion, the mixed solution is added dropwise and stirred for 2 hours, then left to stand and vacuum filtered to obtain a golden yellow precipitate, which is fluoride red powder.

Embodiment 2

[0062] According to K 1.96 Ca 0.04 (Si 0.91 al 0.04 ) F 6 :0.05Mn 4+ The stoichiometric ratio was weighed respectively potassium fluoromanganate, K 2 SiF 6 , AlF 3 and SrF 2 and other raw materials were dissolved in 40wt% HF solution to obtain the hydrofluoric acid solution of potassium fluoromanganate and K 2 SiF 6 , AlF 3 and SrF 2 Two mixed solutions of hydrofluoric acid solution, the two mixed solutions are evenly added dropwise at 60°C in proportion, the mixed solution is added dropwise and stirred for 1.5 hours, then left to stand and vacuum filtered to obtain a golden yellow precipitate, which is red fluorescent powder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com