Environment-friendly high-transparency asphalt and preparation method thereof

A kind of asphalt and transparent technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of vehicle drivers who are prone to visual fatigue, affect the appearance of the road surface, time-consuming and labor-intensive, and achieve the effect of visual comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

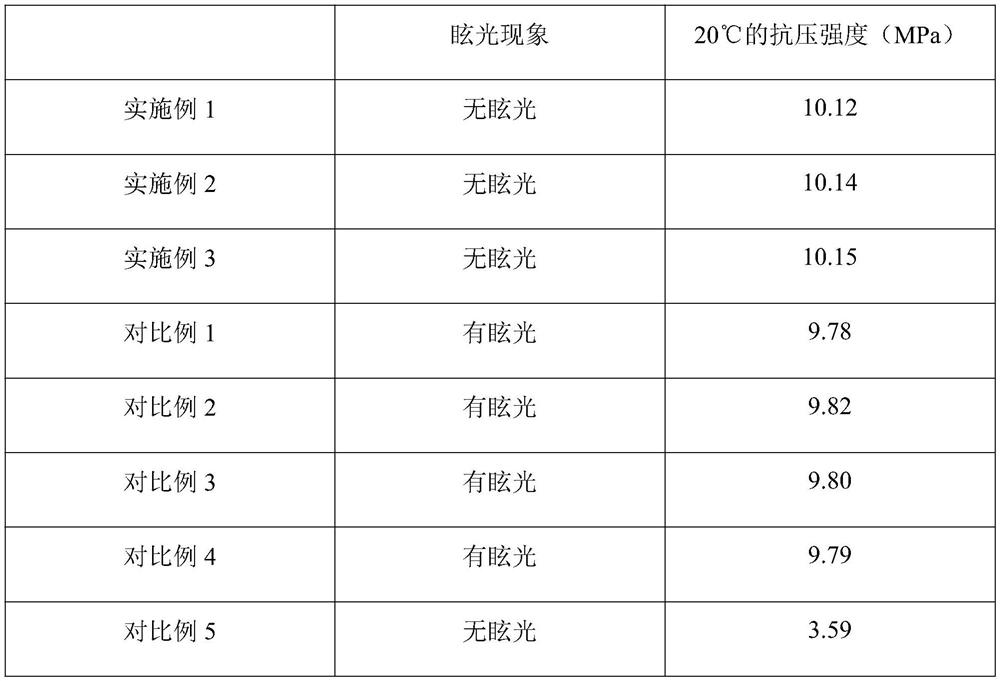

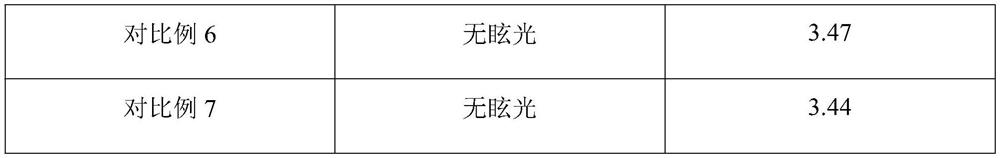

Examples

Embodiment 1

[0030] An environment-friendly high-transparency asphalt, mainly comprising: 70 parts of decolorized asphalt, 7 parts of fluorescent fiber, 0.049 parts of methyl isobutyl carbinol, 1.4 parts of lauryl ammonium chloride, and 35 parts of silicone rubber solution in parts by weight .

[0031] A preparation method of environment-friendly high-transparency asphalt, the preparation method of described environment-friendly high-transparency asphalt mainly comprises the following preparation steps:

[0032] (1) Mix polyester dry slices, trifluoroacetic acid and methyl chloride at a mass ratio of 1:5.5:0.8, and stir at 100 rpm for 5 hours to obtain a polyester solution; the polyester solution and polystyrene microspheres with a particle diameter of 197 nm are Mass ratio 2:3 mixed, disperse 14min under 30kHz, obtain external phase spinning solution, take deionized water as internal phase spinning solution, electrospin to obtain polystyrene microsphere / polyester fiber; The condition of d...

Embodiment 2

[0038] An environment-friendly high-transparency asphalt, mainly comprising: 80 parts of decolorized asphalt, 24 parts of fluorescent fiber, 0.072 parts of methyl isobutyl carbinol, 3.2 parts of dodecyl ammonium chloride, and 48 parts of silicone rubber solution in parts by weight .

[0039] A preparation method of environment-friendly high-transparency asphalt, the preparation method of described environment-friendly high-transparency asphalt mainly comprises the following preparation steps:

[0040] (1) Mix polyester dry chips, trifluoroacetic acid and methyl chloride in a mass ratio of 1:5.82:0.87, stir at 150rpm for 4.5h to obtain a polyester solution; the polyester solution, polystyrene microspheres with a particle size of 201nm Mix by mass ratio 2.5:5, disperse 12min under 36kHz, obtain external phase spinning solution, take deionized water as internal phase spinning solution, electrospin to obtain polystyrene microsphere / polyester fiber; The condition of described elect...

Embodiment 3

[0046] An environment-friendly high-transparency asphalt, mainly comprising: 90 parts of decolorized asphalt, 36 parts of fluorescent fiber, 0.09 part of methyl isobutyl carbinol, 4.5 parts of lauryl ammonium chloride, and 63 parts of silicone rubber solution in parts by weight .

[0047] A preparation method of environment-friendly high-transparency asphalt, the preparation method of described environment-friendly high-transparency asphalt mainly comprises the following preparation steps:

[0048] (1) Mix polyester dry chips, trifluoroacetic acid and methyl chloride in a mass ratio of 1:6.2:0.9, and stir at 200rpm for 4h to obtain a polyester solution; the polyester solution and polystyrene microspheres with a particle diameter of 220nm are pressed Mix at a mass ratio of 3:7, disperse for 9 minutes at 40 kHz to obtain an external phase spinning solution, and use deionized water as an internal phase spinning solution to obtain polystyrene microspheres / polyester fibers by elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com