Normal-temperature curing sulfydryl-imidazole curing agent as well as preparation method and application thereof

An imidazole curing agent and room temperature curing technology, applied in the field of polymer composite materials, can solve the problems of not being able to meet outdoor room temperature curing, poor heat resistance, poor weather resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

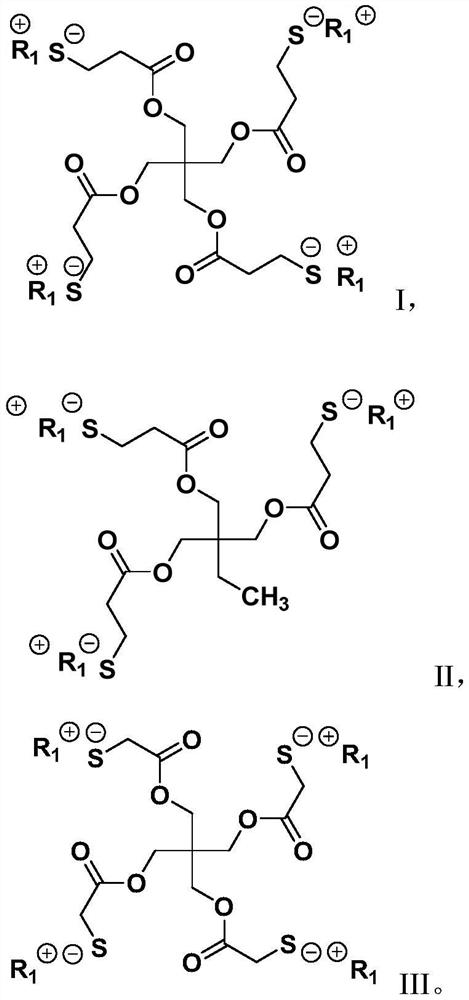

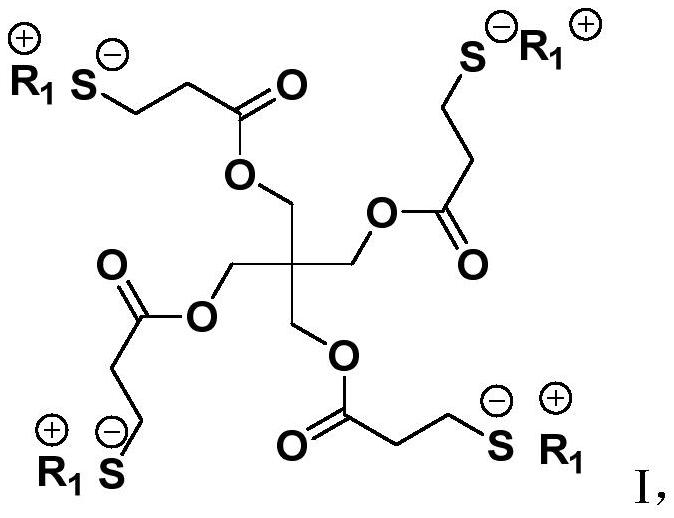

[0050] A kind of normal temperature curing mercapto-imidazole curing agent, the molecular structure is as shown in formula I:

[0051]

[0052] The R 1 Is imidazolyl;

[0053] The preparation method of the mercapto-imidazole curing agent is as follows: dissolve the mercapto curing agent in methanol, condense and reflux at 50°C for 1 hour, then add the imidazole curing agent dissolved in benzyl alcohol, and magnetically stir at 50°C to condense and reflux for 6 hours , after the reaction is cooled to room temperature, the solvent is removed to obtain the mercapto-imidazole curing agent;

[0054] The mercapto curing agent is pentaerythritol tetra-3-mercaptopropionate (CAS No.: 7575-23-7);

[0055] The imidazole curing agent is imidazole;

[0056] The methanol: mercapto curing agent = 1 mL: 100 μg; benzyl alcohol: imidazole curing agent = 1 mL: 100 μg.

[0057] Four kinds of mercapto-imidazole curing agents were prepared by using the molar ratios of mercapto curing agent a...

Embodiment 2

[0059] A kind of normal temperature curing mercapto-imidazole curing agent, the molecular structure is as shown in formula I:

[0060]

[0061] The R 1 is 4-methylimidazolyl;

[0062] The preparation method of the mercapto-imidazole curing agent is as follows: dissolve the mercapto curing agent in methanol, condense and reflux at 50°C for 1 hour, then add the imidazole curing agent dissolved in benzyl alcohol, and magnetically stir at 50°C to condense and reflux for 6 hours , after the reaction is cooled to room temperature, the solvent is removed to obtain the mercapto-imidazole curing agent;

[0063] The mercapto curing agent is pentaerythritol tetra-3-mercaptopropionate (CAS No.: 7575-23-7);

[0064] The imidazole curing agent is 4-methylimidazole;

[0065] The methanol: mercapto curing agent = 1 mL: 100 μg; benzyl alcohol: imidazole curing agent = 1 mL: 100 μg.

[0066] Four kinds of mercapto-imidazole curing agents were prepared by using the molar ratios of mercapt...

Embodiment 3

[0068] A kind of normal temperature curing mercapto-imidazole curing agent, the molecular structure is as shown in formula I:

[0069]

[0070] The R 1 Is 1-methylimidazolyl;

[0071] The preparation method of the mercapto-imidazole curing agent is as follows: dissolve the mercapto curing agent in methanol, condense and reflux at 50°C for 1 hour, then add the imidazole curing agent dissolved in benzyl alcohol, and magnetically stir at 50°C to condense and reflux for 6 hours , after the reaction is cooled to room temperature, the solvent is removed to obtain the mercapto-imidazole curing agent;

[0072] The mercapto curing agent is pentaerythritol tetra-3-mercaptopropionate (CAS No.: 7575-23-7);

[0073] The imidazole curing agent is 1-methylimidazole;

[0074] The methanol: mercapto curing agent = 1 mL: 100 μg; benzyl alcohol: imidazole curing agent = 1 mL: 100 μg.

[0075] Four kinds of mercapto-imidazole curing agents were prepared by using the molar ratios of mercapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com