LED material for multifunctional curved surface display screen and manufacturing method thereof

A display screen and multi-functional technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as single luminescence spectrum and brittle pure gallium nitride chip materials, and achieve stable chemical properties, high mechanical strength, and material utilization. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

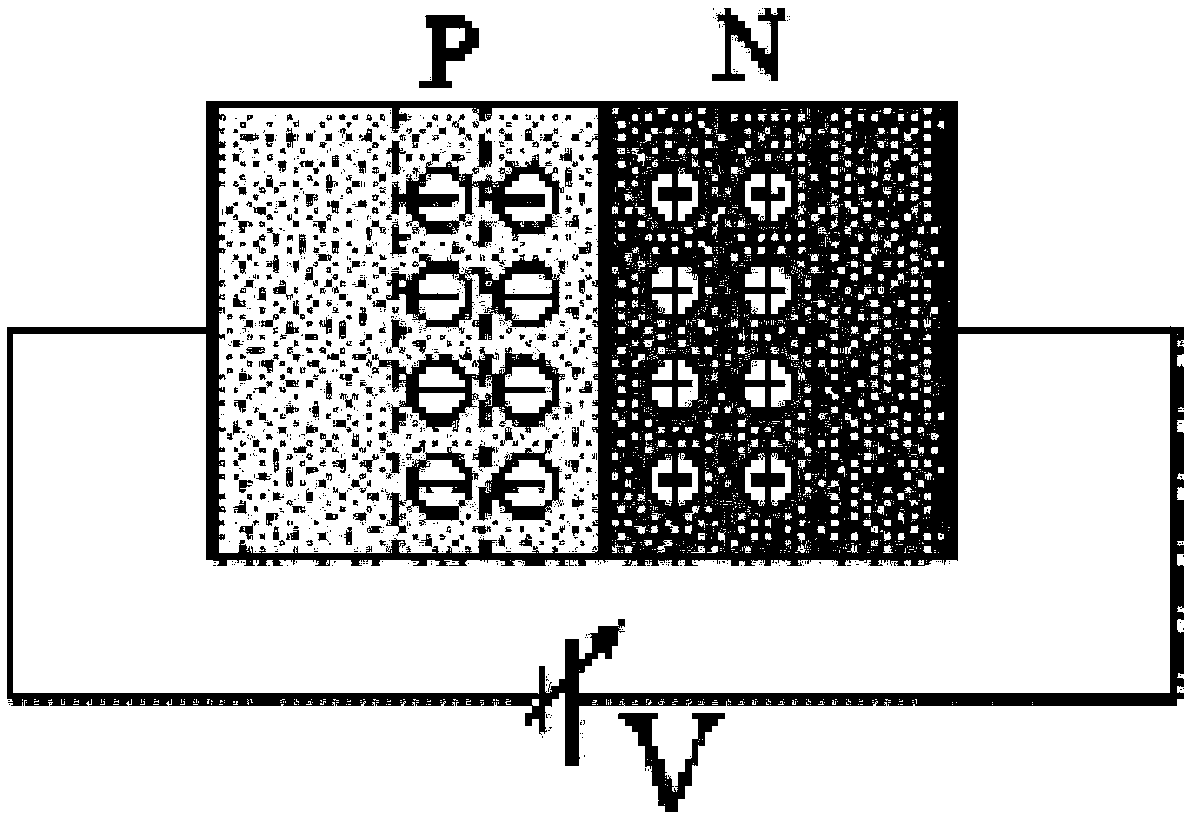

Image

Examples

Embodiment 1

[0026] A LED material for a multi-functional curved display screen, the LED material is specifically composed of an LED chip and an LED packaging material, wherein the LED chip is specifically made of silicon carbide as a substrate, gallium nitride as a core body, and two electrodes respectively distributed L-shaped electrodes on the surface and bottom of the core, where 2.5% silicon dioxide, 1.6% indium, 1.2% arsenic and 0.6% aluminum are added to the gallium nitride core according to the total mass of gallium nitride; LED packaging The specific material is: polymerize vinyl silicon and siloxane into vinyl silicon polymer, polymerize polyhydrogen siloxane and vinyl hydrogen silicone resin into hydrogen-containing polymer, and then combine the two polymers Silicone resin synthesized under the action of inhibitor and platinum catalyst.

[0027] The method for manufacturing the LED material for the above-mentioned multifunctional curved display screen comprises the following ste...

Embodiment 2

[0044] The whole is consistent with Example 1, the difference is:

[0045] The method for manufacturing the LED material for the above-mentioned multifunctional curved display screen comprises the following steps:

[0046] 1) LED chip preparation

[0047] ② Prepare 80nm thick silicon carbide substrate;

[0048] ⑤ Stabilize at 100°C for 20 minutes to obtain the required LED chips;

Embodiment 3

[0050] The whole is consistent with Example 1, the difference is:

[0051] The method for manufacturing the LED material for the above-mentioned multifunctional curved display screen comprises the following steps:

[0052] 1) LED chip preparation

[0053] ② Prepare a 150nm thick silicon carbide substrate;

[0054] ⑤ Stabilize at 120°C for 30 minutes to obtain the required LED chips;

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com