A frequency stable low dielectric microwave dielectric ceramic material and its preparation method

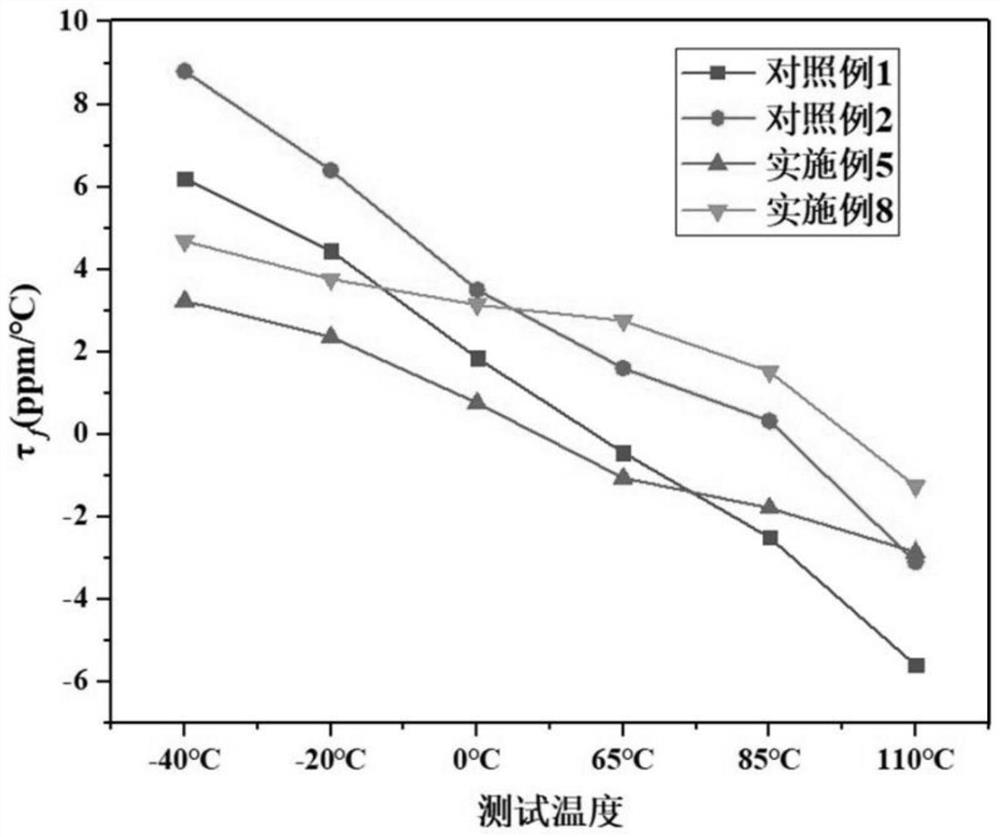

A technology of microwave dielectric ceramics and ceramic materials, applied in the field of material science, can solve the problems of easily limited material application, difficult frequency temperature coefficient, poor frequency stability of related devices, etc., to achieve good process operability and reproducibility, and optimized frequency. The effect of good temperature coefficient and microwave dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Synthesis of main phase ceramic material A:

[0030] According to the chemical formula Mg 2.00 co 0.10 SiO 4.10 Measuring ratio weighing raw materials MgO, SiO 2 and CoO, add deionized water according to the ratio of mixture to deionized water 1:3, mix and grind for 20 hours, then dry in an oven at 120°C, grind with a quartz mortar and pass through a 40-mesh sieve, and then put the powder into alumina The crucible was calcined at 1250°C for 3 hours to obtain the main phase calcined powder A.

[0031] 2) Synthesis of auxiliary phase ceramic material B:

[0032] According to the chemical composition 0.99CaO·0.11SrO-0.06La 2 o 3 0.05Al 2 o 3 -1.00TiO 2 Weigh raw material CaCO 3 , SrCO 3 , La 2 o 3 、Al 2 o 3 and TiO 2 Mix, add deionized water according to the ratio of mixture and deionized water 1:2, mix and grind for 16 hours, then dry in an oven at 120°C, grind with a quartz mortar and pass through a 40-mesh sieve, and then put the powder into alumina ...

Embodiment 2

[0035] 1) Synthesis of main phase ceramic material A:

[0036] According to the chemical formula Mg 2.02 Zn 0.05 SiO 4.07 Measuring ratio weighing raw materials MgO, SiO 2 and ZnO, add deionized water according to the ratio of mixture to deionized water 1:3, mix and grind for 16 hours, then dry in an oven at 120°C, grind with a quartz mortar and pass through a 40-mesh sieve, and then put the powder into alumina The crucible was calcined at 1200°C for 3 hours to obtain the main phase calcined powder A.

[0037] 2) Synthesis of auxiliary phase ceramic material B:

[0038] According to the chemical composition 1.05CaO·0.12SrO-0.08Nd 2 o 3 0.06Al 2 o 3 -1.05TiO 2 Weigh raw material CaCO 3 , SrCO 3 、Nd 2 o 3 、Al 2 o 3 and TiO 2 For mixing, add deionized water according to the ratio of mixture and deionized water 1:2, mix and grind for 20 hours, then dry in an oven at 120°C, grind with a quartz mortar and pass through a 40-mesh sieve, and then put the powder into alu...

Embodiment 3

[0041] 1) Synthesis of main phase ceramic material A:

[0042] According to the chemical formula Mg 1.95 co 0.10 SiO 4.05 Measuring ratio weighing raw materials MgO, SiO 2 and CoO, add deionized water according to the ratio of mixture to deionized water 1:3, mix and grind for 20 hours, then dry in an oven at 120°C, grind with a quartz mortar and pass through a 40-mesh sieve, and then put the powder into alumina The crucible was calcined at 1150°C for 4 hours to obtain the main phase calcined powder A.

[0043] 2) Synthesis of auxiliary phase ceramic material B:

[0044] According to the chemical composition 1.25CaO·0.20SrO-0.15La 2 o 3 0.12Al 2 o 3 -1.20TiO 2 Weigh raw material CaCO 3 , SrCO 3 , La 2 o 3 、Al 2 o 3 and TiO 2 Mix, add deionized water according to the ratio of mixture and deionized water 1:2, mix and grind for 16 hours, then dry in an oven at 120°C, grind with a quartz mortar and pass through a 40-mesh sieve, and then put the powder into alumina ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com