Preparation method of nickel carbide nanometer material with different morphologies

A nanomaterial, nickel carbide technology, applied in the field of material science, can solve the problem of less special morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

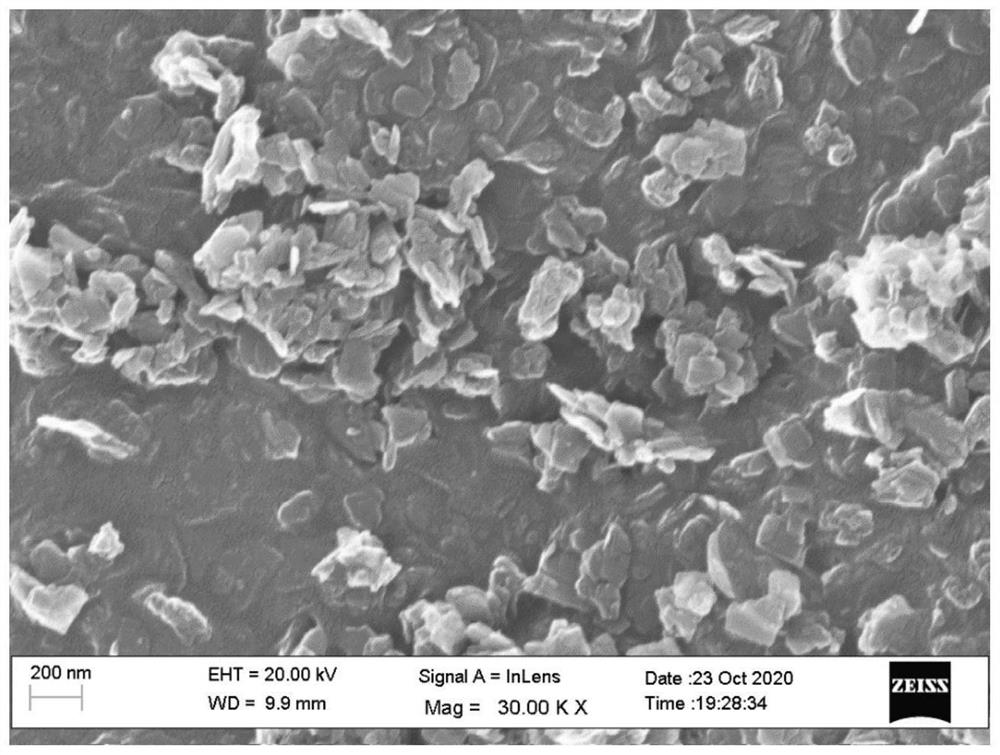

[0026] In this embodiment, the preparation of nickel carbide nanomaterials whose morphology is irregular nanosheets includes the following steps:

[0027] Step 1, preparing sodium sulfate solution and triethanolamine solution respectively, mixing the two solutions according to the mol ratio of sodium sulfate and triethanolamine as 4:3, and recording it as solution A, then adding potassium tetracyanonickelate solution in solution A , adding ammonia solution as precipitant, adding absolute ethanol as dispersant; wherein, the volume ratio of potassium tetracyanonickelate solution to solution A is 1:1, the volume ratio of ammonia solution to solution A is 1:40, no The volume ratio of water ethanol to solution A is 1:20;

[0028] Step 2, sealing the mixed solution obtained in Step 1 in a hydrothermal reaction kettle, performing a solvothermal reaction at 30° C. for 24 hours, and then naturally cooling to room temperature;

[0029] Step 3: Centrifuge the reaction product obtained i...

Embodiment 2

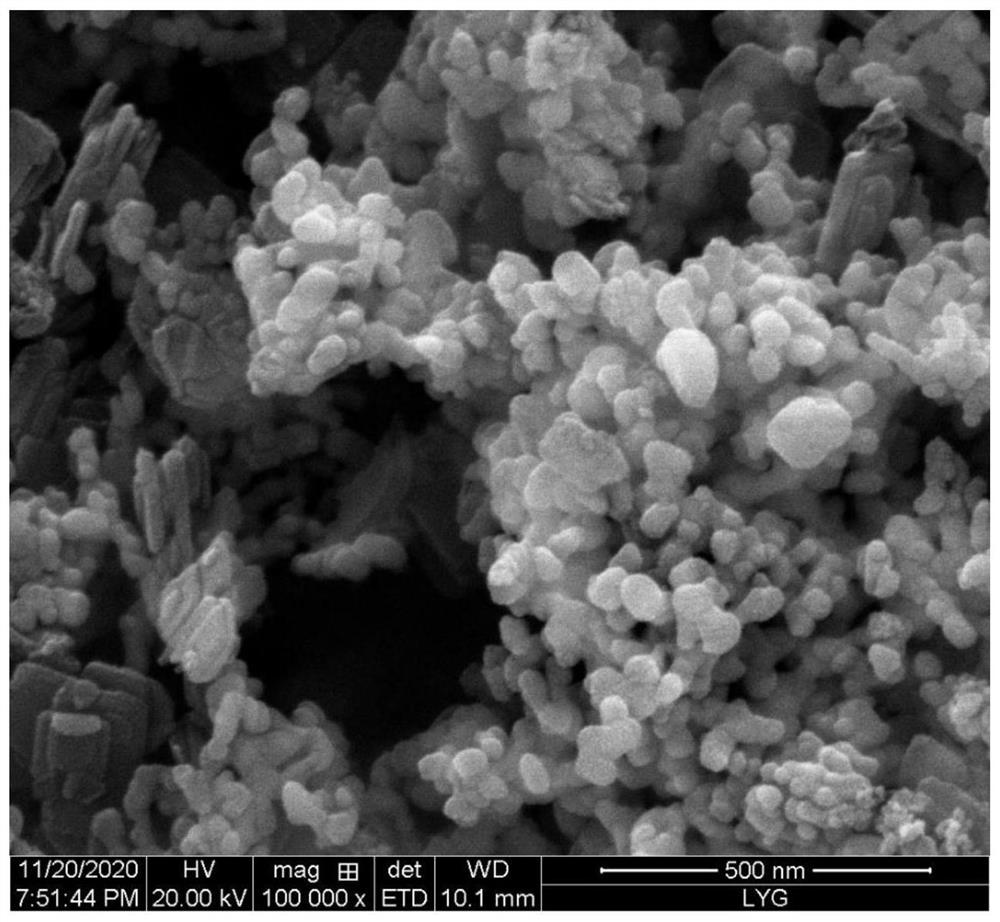

[0033] In this embodiment, the preparation of nickel carbide nanomaterials whose morphology is spherical nanoparticles includes the following steps:

[0034] Step 1, preparing sodium sulfate solution and triethanolamine solution respectively, mixing the two solutions according to the mol ratio of sodium sulfate and triethanolamine as 4:3, and recording it as solution A, then adding potassium tetracyanonickelate solution in solution A , adding ammonia solution as precipitant, adding absolute ethanol as dispersant; wherein, the volume ratio of potassium tetracyanonickelate solution to solution A is 1:1, the volume ratio of ammonia solution to solution A is 1:40, no The volume ratio of water ethanol to solution A is 1:20;

[0035] Step 2, sealing the mixed solution obtained in Step 1 in a hydrothermal reaction kettle, performing a solvothermal reaction at 60° C. for 24 hours, and then naturally cooling to room temperature;

[0036] Step 3: Centrifuge the reaction product obtaine...

Embodiment 3

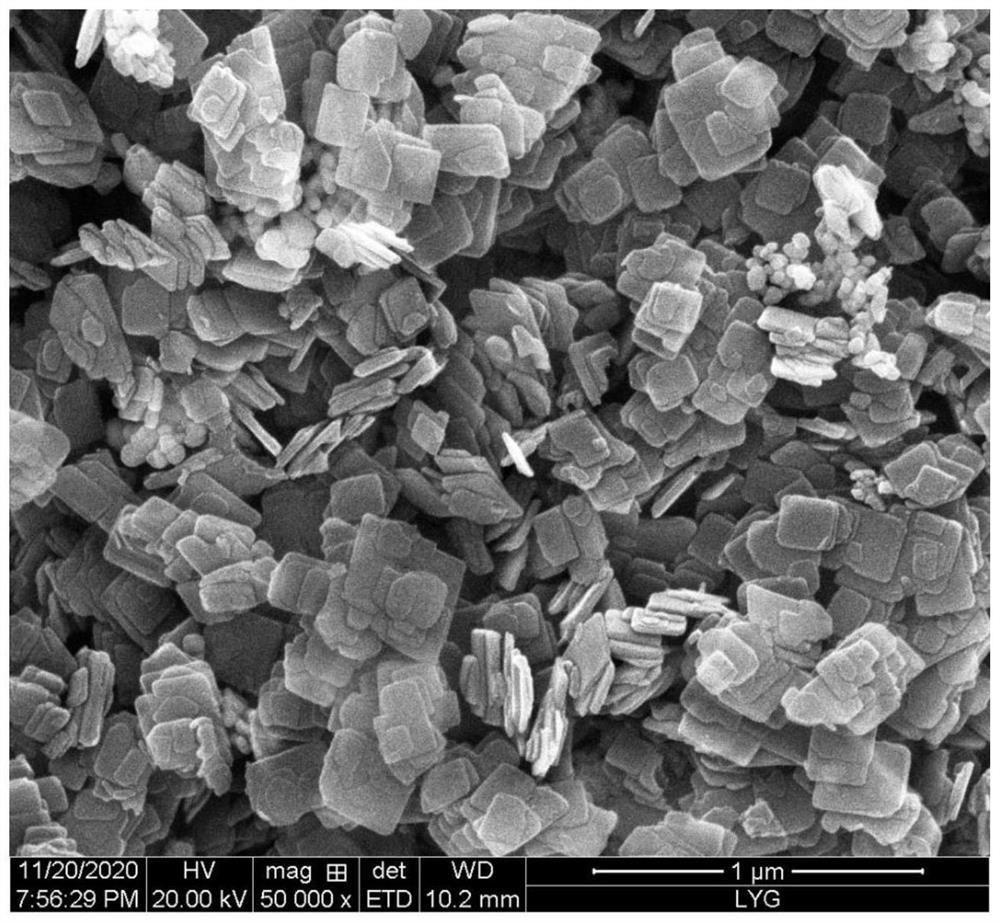

[0040] In this embodiment, the preparation of nickel carbide nanomaterials whose morphology is regular tetragonal nanosheets includes the following steps:

[0041] Step 1, preparing sodium sulfate solution and triethanolamine solution respectively, mixing the two solutions according to the mol ratio of sodium sulfate and triethanolamine as 4:3, and recording it as solution A, then adding potassium tetracyanonickelate solution in solution A , adding ammonia solution as precipitant, adding absolute ethanol as dispersant; wherein, the volume ratio of potassium tetracyanonickelate solution to solution A is 1:1, the volume ratio of ammonia solution to solution A is 1:40, no The volume ratio of water ethanol to solution A is 1:20;

[0042] Step 2, sealing the mixed solution obtained in Step 1 in a hydrothermal reaction kettle, performing a solvothermal reaction at 90° C. for 24 hours, and then naturally cooling to room temperature;

[0043] Step 3: Centrifuge the reaction product o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com