Preparation method of composite electrode material and product thereof

A composite electrode and electrode sheet technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of high production cost, difficulty in large-scale production, complex process, etc., and achieve low cost, simplified preparation process, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, the preparation method of carbon dot / conductive polymer composite electrode material

[0036] plan 1:

[0037] (1) Synthesis of carbon dots: Dissolve urea and citric acid in water at a mass ratio of 1:1.5, with a solid-liquid ratio of 10, and then hydrothermally synthesize carbon dots; the temperature of hydrothermal synthesis is 180°C, and the time is 8h;

[0038](2) Carbon dot activation: Mix the carbon dots prepared in step (1) with KOH at a mass ratio of 2:1, heat and activate in an argon atmosphere, and the heating rate is 2°C / min, and the temperature is raised to 600°C Keep it warm for 2 hours, and finally cool to room temperature. After carbonization, the crude product is obtained, and further washed with 0.3% dilute hydrochloric acid solution and water to neutrality;

[0039] (3) Soak the activated carbon dots in step (2) in 50 mg / mL of FeCl 3 Ethanol solution for 5 minutes, filtered out and dried;

[0040] (4) The product of step (3) is placed ...

Embodiment 2

[0087] Embodiment 2, the electrode tablet of preparation capacitor constitutes electrode system

[0088] Activated carbon / conductive polymer composite electrode material, conductive agent Super P and binder polytetrafluoroethylene solution (solid content 60wt%) were dispersed in absolute ethanol with a mass ratio of 8:1:1 and fully ground to obtain Viscous slurry; then evenly scrape the slurry onto a square nickel foam current collector with a side length of 1cm, take it out after air-drying at 80°C overnight, and then place it on a powder tablet press with a pressure of 2MPa Press the sheet for 15s to prepare the electrode sheet of the capacitor.

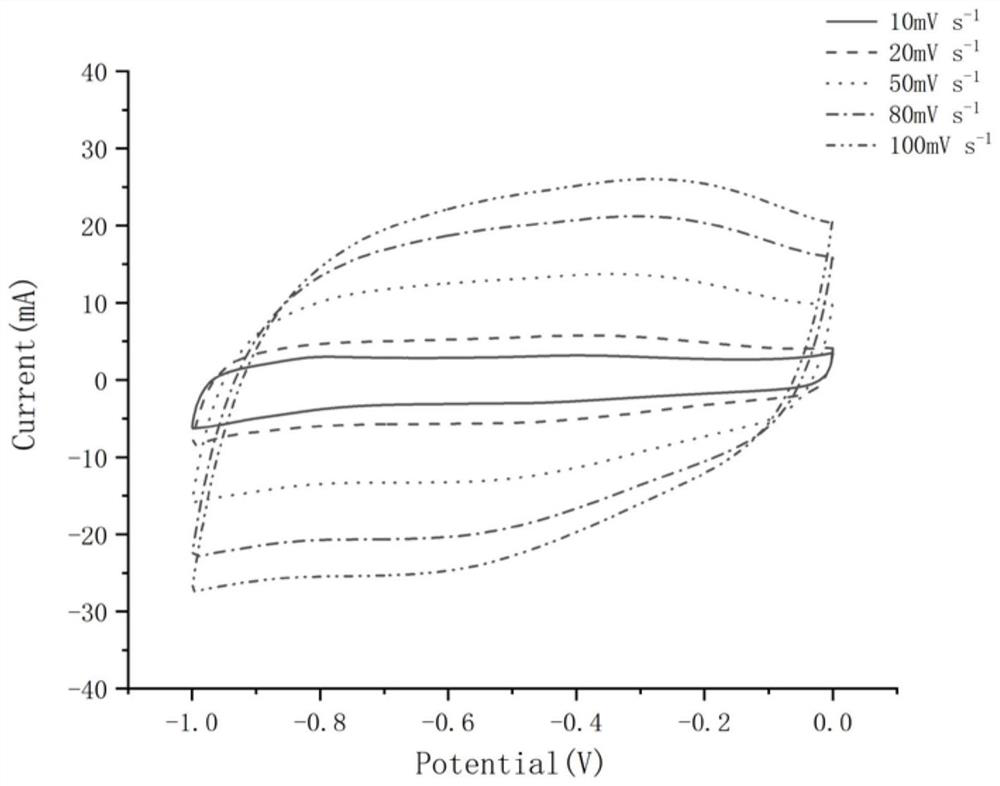

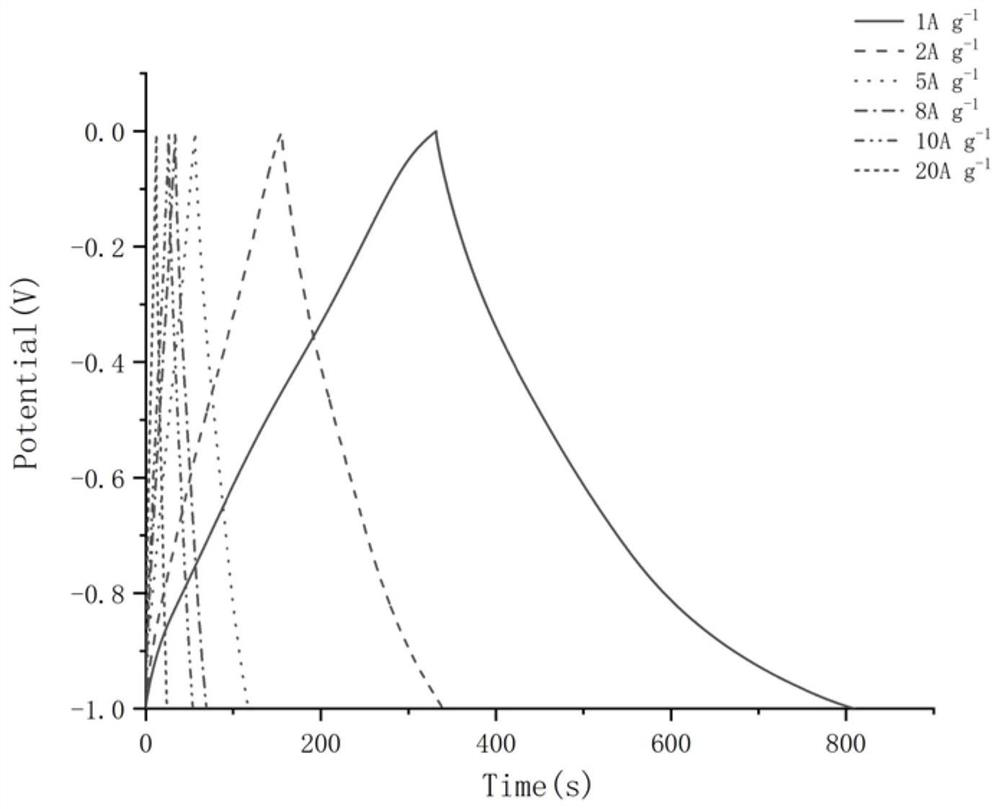

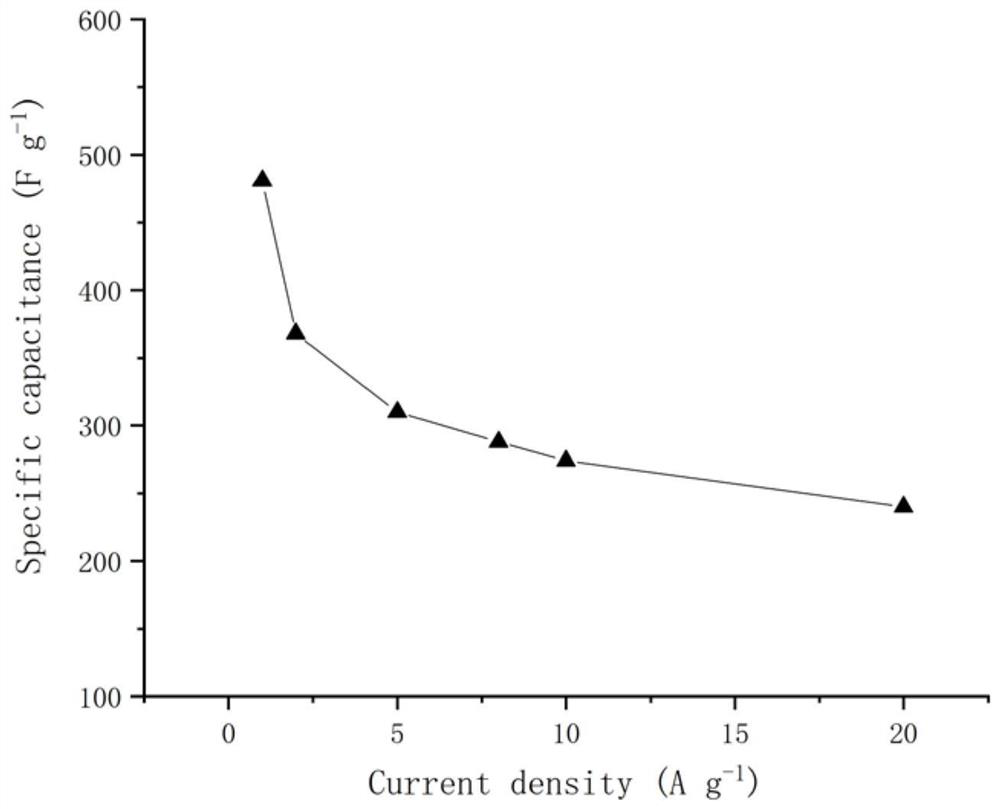

[0089] Under the three-electrode system, the electrode sheet is used as the working electrode, the Pt sheet is used as the counter electrode, and the Hg / HgO electrode is used as the reference electrode. / s Electrochemical tests at different scan speeds.

[0090] figure 1 The composite electrode material prepared by the hydrother...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com