High-elasticity high-nickel-alloy card clothing steel wire rod and preparation method thereof

An alloy needle and high elasticity technology, applied in the field of high elasticity and high nickel alloy card clothing steel wire and its preparation, can solve the problems of poor compactness, short service life of steel wire, easy dezincification, etc., to overcome the relatively large dispersion of strength, Improve the strength and ductility, promote the effect of nucleation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

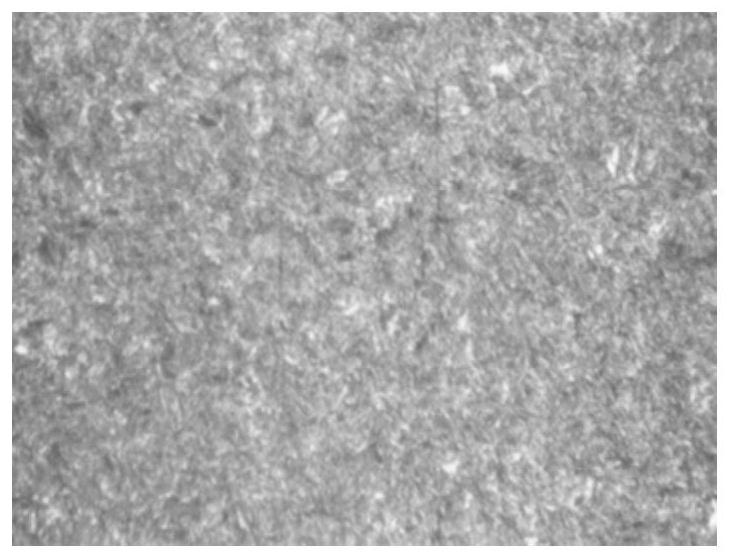

Image

Examples

Embodiment 1

[0035] A method for preparing a high-elasticity high-nickel alloy card clothing steel wire rod, according to the following steps:

[0036] (1) The weight percentage of the chemical composition of the wire is as follows: C: 0.6%, Si: 0.1%, Mn: 0.4%, Ni: 2%, Cr: 0.1%, Ce: 0.02%, S: ≤0.005%, P: ≤ 0.005%, the balance is Fe and unavoidable impurity elements. It is smelted in converter or electric furnace, and then refined in refining furnace. During refining, it is combined with synthetic slag to fully deoxidize and remove inclusions. After LF refining, it is matched with VD furnace vacuum treatment for further degassing and removal of inclusions. After refining, rare earth elements are added before VD furnace vacuum treatment, and molten steel is poured. into billets.

[0037] (2) The billet is heated at a rate of 30-32 °C / s to 1100-1150 °C, kept at high temperature for 12 hours, then cooled at a rate of 5-8 °C / s to a deformation temperature of 1000-1050 °C, and kept at high temp...

Embodiment 2

[0048] A preparation method of a high-elasticity high-nickel alloy card clothing steel wire rod, according to the following steps:

[0049] (1) The weight percentage of the chemical composition of the wire is as follows: C: 0.8%, Si: 0.2%, Mn: 0.4%, Ni: 3.2%, Cr: 0.15%, Ce and Y mixture (Ce and Y according to the mass ratio 1:1): 0.01%, S: ≤0.005%, P: ≤0.005%, the balance is Fe and unavoidable impurity elements.

[0050] (4) Prepare materials according to the design composition, use converter or electric furnace for smelting, and then refine in refining furnace. During refining, cooperate with synthetic slag to fully deoxidize and remove inclusions. After LF refining, match VD furnace vacuum treatment to further degas and remove inclusions. After refining, VD furnace vacuum Rare earth elements are added before treatment, molten steel is poured into a billet, and the billet is heated to 1100-1150 °C at a rate of 33-35 °C / s, kept at high temperature for 10-12 hours, and then coo...

Embodiment 3

[0061] A method for preparing a high-elasticity high-nickel alloy card clothing steel wire rod, according to the following steps:

[0062] (1) The weight percentage of the chemical composition of the wire is as follows: C: 0.6%, Si: 0.1%, Mn: 0.4%, Ni: 2%, Cr: 0.1%, Ce: 0.02%, S: ≤0.005%, P: ≤ 0.005%, the balance is Fe and unavoidable impurity elements. It is smelted in converter or electric furnace, and then refined in refining furnace. During refining, it is combined with synthetic slag to fully deoxidize and remove inclusions. After LF refining, it is matched with VD furnace vacuum treatment for further degassing and removal of inclusions. After refining, rare earth elements are added before VD furnace vacuum treatment, and molten steel is poured. into billets.

[0063] (2) The billet is heated at a rate of 30-32 °C / s to 1100-1150 °C, kept at high temperature for 12 hours, then cooled at a rate of 5-8 °C / s to a deformation temperature of 1000-1050 °C, and kept at high temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com