Yttrium-zirconium-iron-aluminum alloy material, preparation method and application

An aluminum alloy material and aluminum alloy technology, applied in chemical instruments and methods, non-metallic elements, inorganic chemistry, etc., to achieve the effects of lowering dehydrogenation temperature, lowering stability, and stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] On the other hand, the preparation method of the yttrium-zirconium-iron-aluminum alloy material provided by the embodiments of the present invention may include the following steps:

[0034] Step S11: Weigh and mix the metal bulk materials of yttrium, zirconium, iron and aluminum according to the ratio of the substances in the general chemical formula, melt at a temperature higher than 1600°C, and obtain an alloy ingot after cooling.

[0035] As can be seen from the foregoing, the general chemical formula of yttrium, zirconium, iron and aluminum is Y 1-x Zr x Fe 2-y Al y , where 0.25<x<0.45, 0.1<y<0.4, the proportion of the four metal materials can be determined. It should be noted that, because yttrium metal is easy to vaporize, in actual operation, 1 %-2% margin. Then, the weighed metal bulk materials of yttrium, zirconium, iron and aluminum are mixed uniformly, melted at a temperature higher than 1600°C, and cooled to obtain an alloy ingot.

[0036] In one embod...

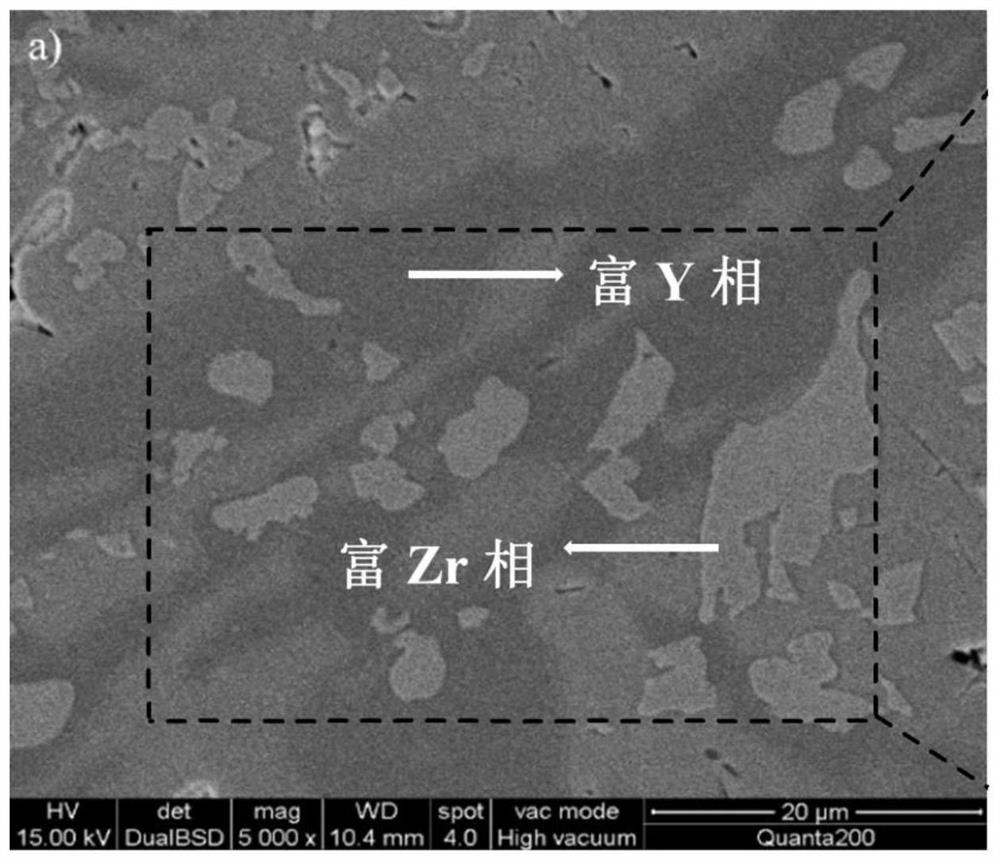

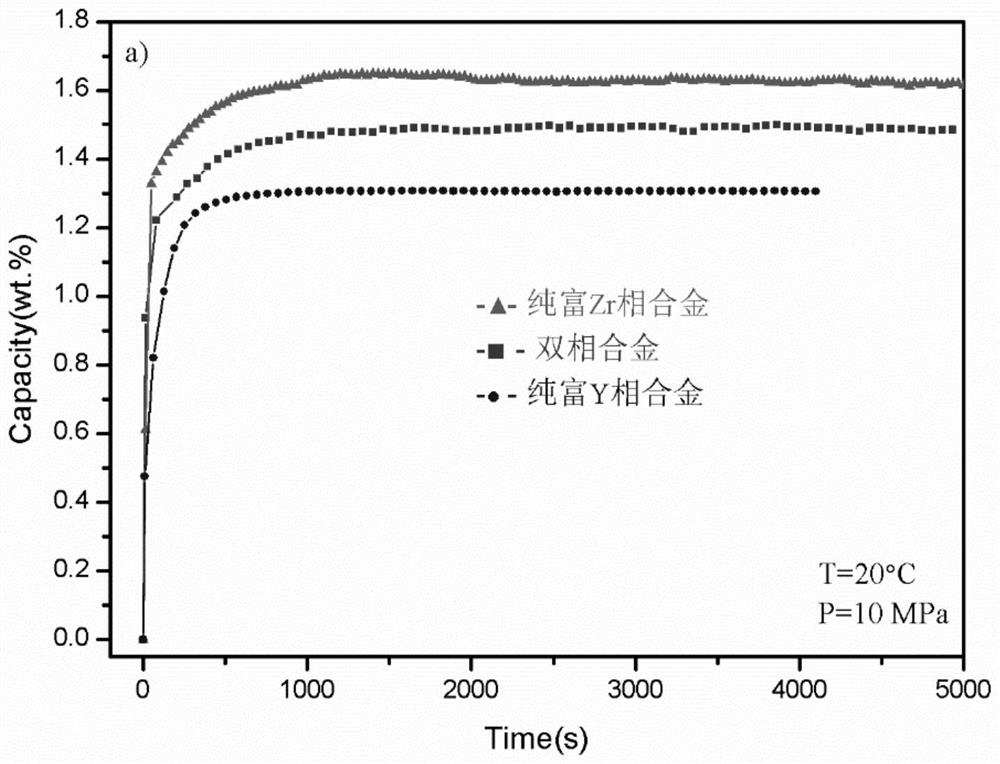

Embodiment 1

[0050] This embodiment provides a kind of yttrium-zirconium-iron-aluminum alloy material, the chemical general formula of described yttrium-zirconium-iron-aluminum alloy material is Y 0.67 Zr 0.33 Fe 1.7 Al 0.3 , the preparation method of yttrium-zirconium-iron-aluminum alloy material comprises the following steps:

[0051] Step S311, the yttrium block, zirconium block, iron block and aluminum block (purity not less than 99wt.%) according to the general chemical formula Y 0.67 Zr 0.33 Fe 1.7 Al 0.3 The ratio of the amount of material is weighed to take yttrium block, zirconium block, iron block and iron block and mix them uniformly; smelt at 1600 ° C for 5 minutes in an electric arc melting furnace, and obtain an alloy ingot after cooling.

[0052] Step S312: Turn over the alloy ingot obtained, and re-melt and cool, so that the smelting is repeated 5 times. The re-melting was carried out in an electric arc melting furnace at a melting temperature of 1600°C and a melting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com