Doped Li-Mg-N-H hydrogen storage material

A hydrogen storage material, 2-xlih-yrbnm technology, applied in various metal hydrides, fuel cells, hydrogen production and other directions, can solve the problems of high hydrogen release temperature and slow hydrogen release rate, and achieve high hydrogen storage capacity. , The effect of fast hydrogen release and accelerated hydrogen release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

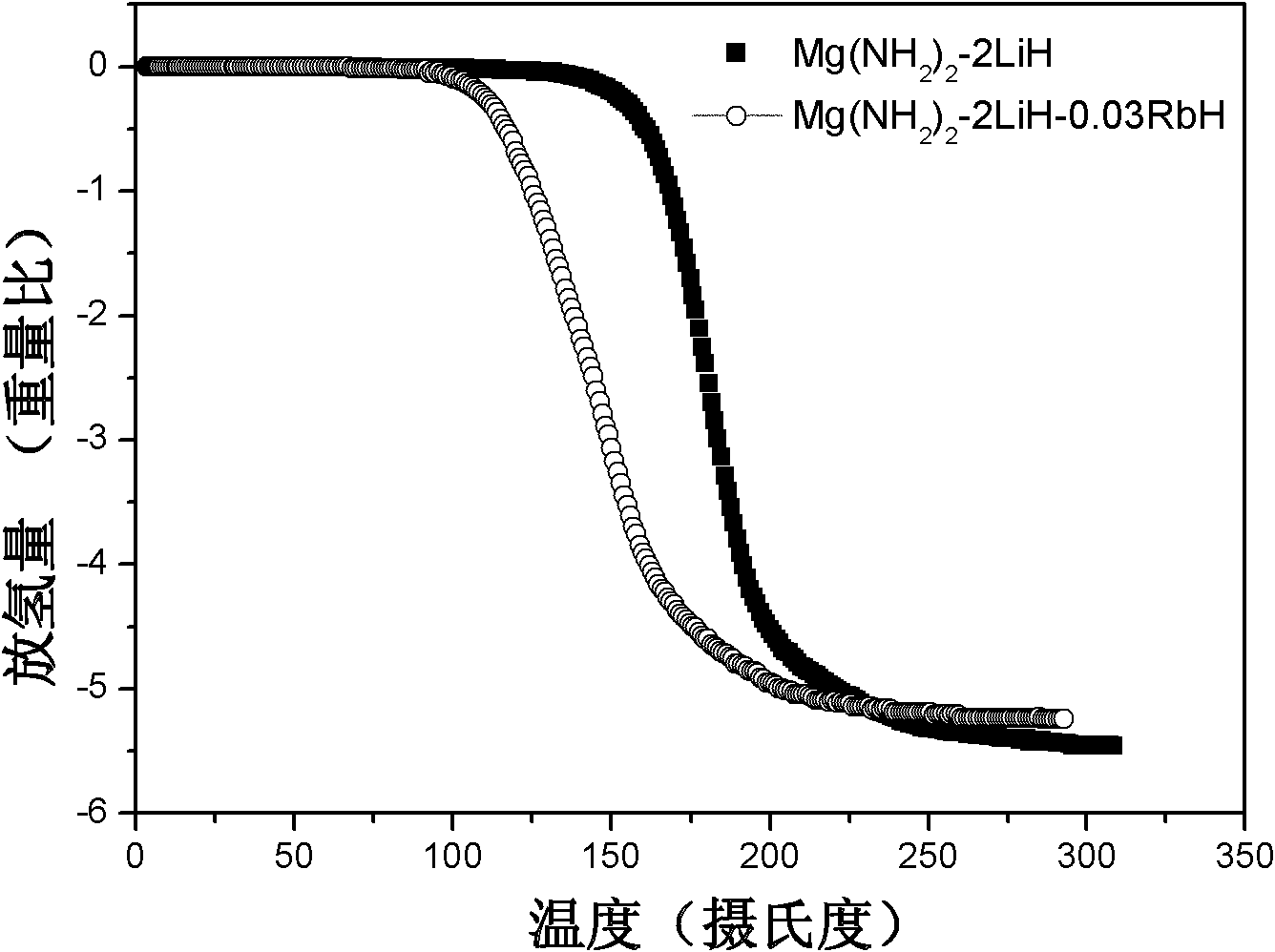

[0019] In a glove box filled with Ar gas, Mg(NH 2 ) 2 and LiH are mixed with 0.01, 0.03, 0.05, 0.08, 0.1, 0.12 and 0.15 moles of RbH respectively, and put into a sealable stainless steel tank. Ball milling was carried out on a ball mill with a ball-to-material ratio of 50:1 and a rotational speed of 500 rpm. The samples after ball milling were tested for hydrogen desorption performance. Table 1 lists the starting temperature and amount of hydrogen desorption of the above mixed samples. From the data in the table, it can be seen that the hydrogen release amount of all the above samples is above 4.0 wt%, and the hydrogen release start temperature is about 60-110°C.

[0020] Table 1 Mg(NH 2 ) 2 -2LiH-yRbH sample hydrogen release start temperature and hydrogen release amount

[0021] sample

[0022] Mg(NH 2 ) 2 -2LiH-0.12RbH

Embodiment 2

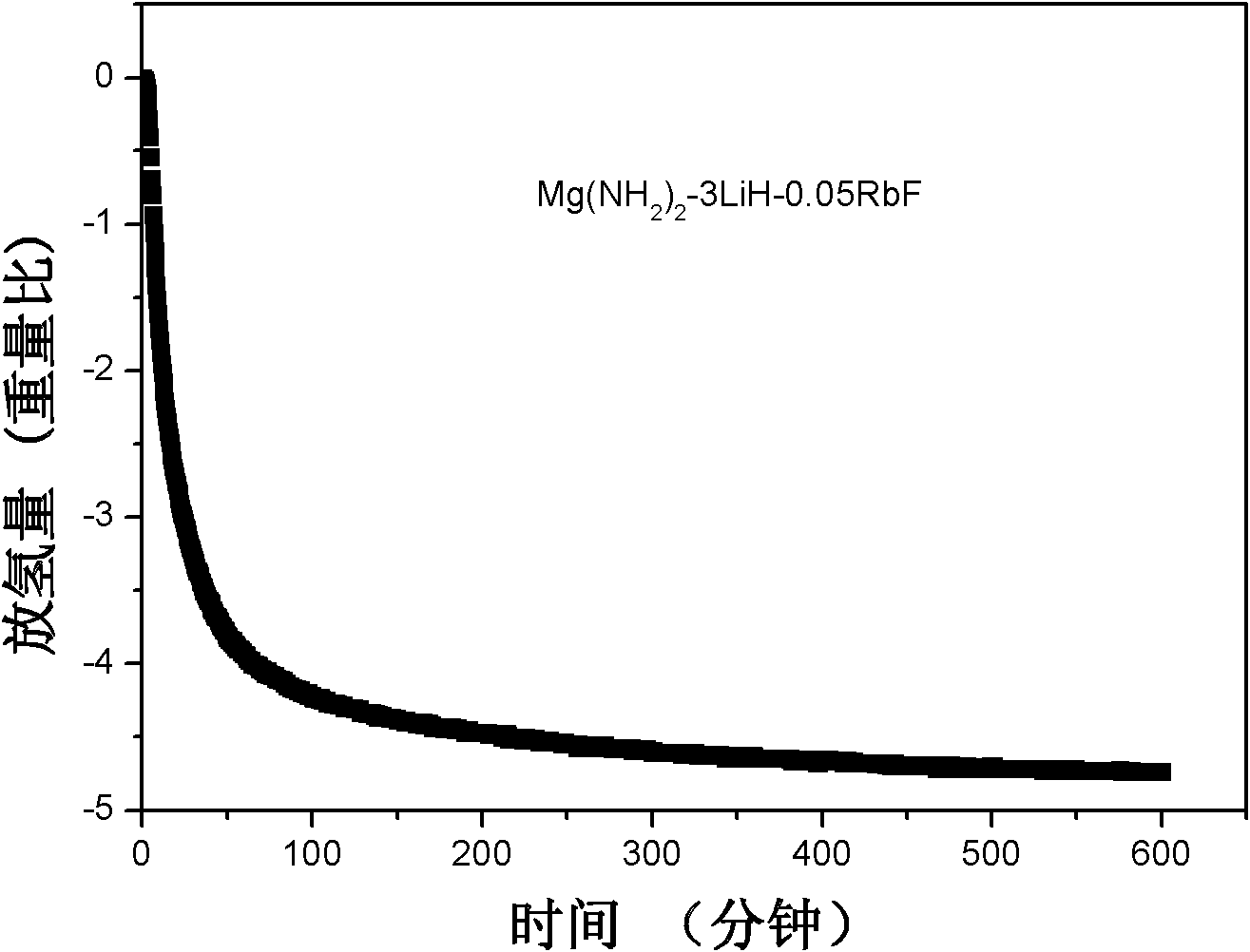

[0027] In a glove box filled with N2 gas, Mg(NH 2 ) 2 and LiH were mixed with 0.05 moles of RbF, RbCl, RbBr and RbI respectively, put into a sealable stainless steel tank, protected by nitrogen, and ball milled on a planetary ball mill with a ball-to-material ratio of 80:1 and a speed of 450rpm. The samples obtained after ball milling were tested for dehydrogenation. Table 2 lists the hydrogen desorption properties of the above mixed samples. It can be seen from Table 2 that the hydrogen desorption of all samples can be carried out below 100°C, and the hydrogen desorption amount is above 4.0wt%. The isothermal dehydrogenation test found that all the samples could release more than 3.0wt% hydrogen within 40 minutes at 150°C.

[0028] figure 2 Shown as Mg(NH 2 ) 2 -3LiH-0.05RbF sample isothermal dehydrogenation curve. The results showed that Mg(NH 2 ) 2 The -3LiH-0.05RbF sample can achieve a hydrogen desorption capacity of more than 3.5wt% within 40min.

[0029] Table ...

Embodiment 3

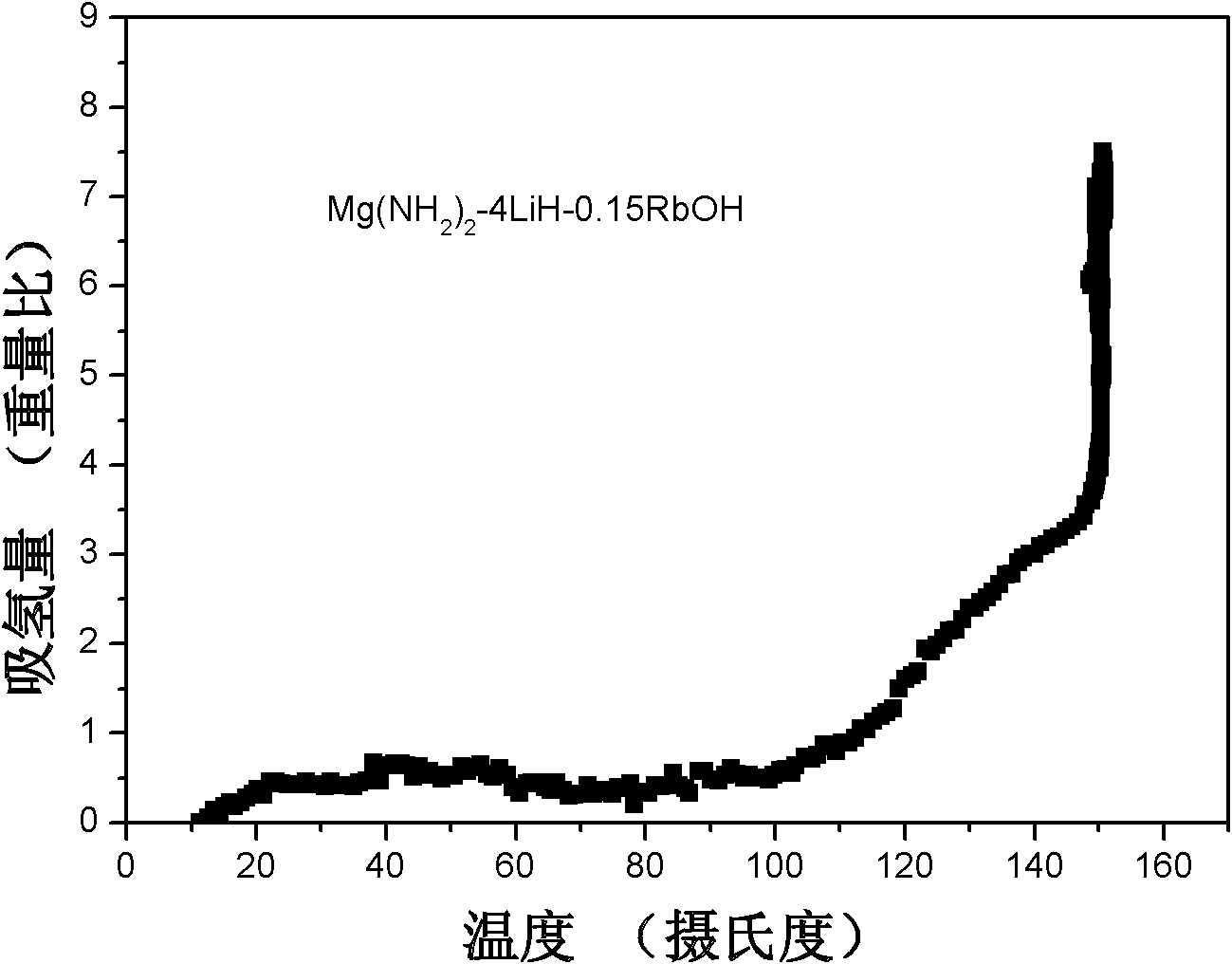

[0032] In a glove box filled with Ar gas, Mg(NH 2 ) 2and LiH are mixed with 0.02, 0.04, 0.06, 0.08, 0.1, 0.12, 0.15 moles of RbOH respectively, put into a sealable stainless steel tank, and then vacuumize the ball mill tank for vacuum protection. Ball milling was performed on a planetary ball mill with a ball-to-material ratio of 90:1 and a rotational speed of 350 rpm. The mixture obtained by ball milling was first tested for dehydrogenation. Table 3 lists the hydrogen desorption performance data of the above mixed samples. As a result, it was found that the initial dehydrogenation temperature of the above-mentioned mixed samples was all below 110° C., and the hydrogen desorption amount remained above 4.0 wt%. The samples after dehydrogenation were further tested for hydrogen absorption performance. The initial hydrogen pressure of hydrogen absorption was 100 atm, and the initial hydrogen absorption temperature of all samples after dehydrogenation was lower than 80°C. ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com