A kind of composite hydrogen storage material and preparation method thereof

A technology of hydrogen storage materials and lithium hydride, which is applied in the field of composite hydrogen storage materials and its preparation, can solve the problems of attenuation of hydrogen absorption and desorption, particle size, and dispersion degree of grain size catalysts, etc., to achieve improved hydrogen storage performance, Improved thermodynamic and kinetic properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In addition, the present application also provides a method for preparing a composite hydrogen storage material, comprising the following steps.

[0029] Step 1: Weigh magnesium amide, lithium hydride and alkali metal silicon hydride and mix them into a ball mill. Wherein, the molar ratio of magnesium amide to lithium hydride is 1:2, and the addition amount of alkali metal silicon hydride is 1-15 mol %, for example, 1 mol %, 4 mol %, 9 mol %, 15 mol % and the like.

[0030] Preferably, the alkali metal silicon hydride comprises potassium silicon hydride KSiH 3 , Rubidium silicon hydride RbSiH 3 and cesium silicon hydride CsSiH 3 at least one of them.

[0031] In step 2, the ball mill jar is evacuated and filled with hydrogen pressure.

[0032] Preferably, the hydrogen pressure is 2-5 MPa, such as 2 MPa, 3 MPa, 5 MPa and the like.

[0033] Wherein, before the step that the ball mill tank is evacuated and filled with hydrogen pressure, the following steps are also incl...

Embodiment 1

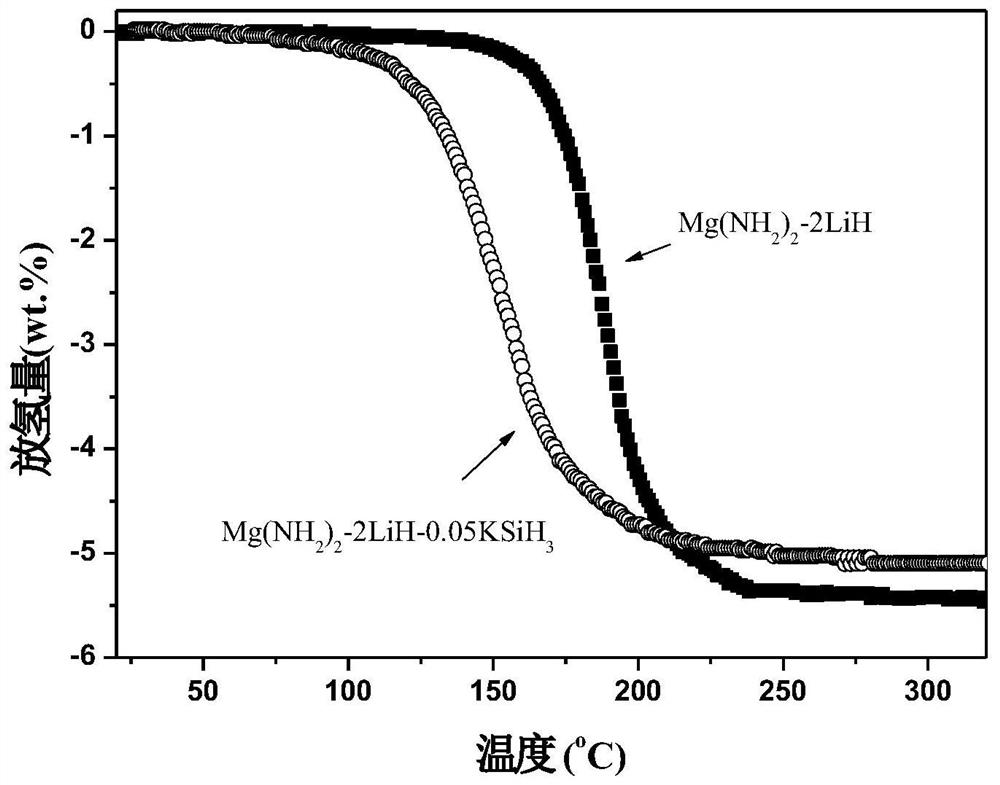

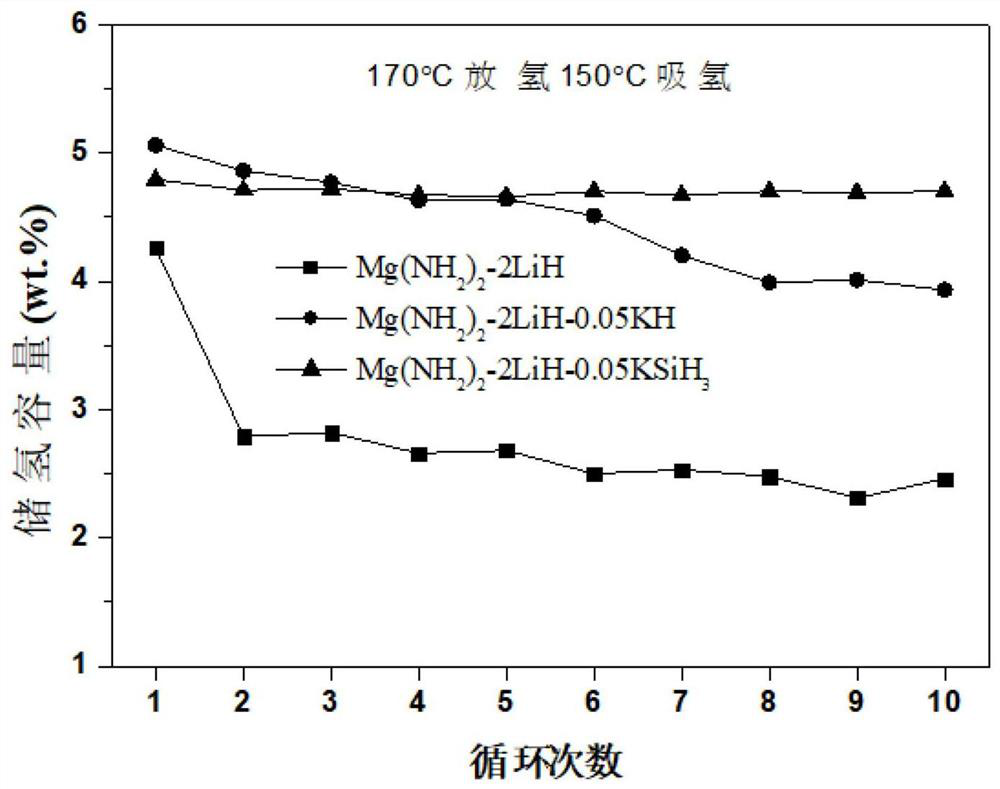

[0043] Samples were weighed in an argon atmosphere glove box with magnesium amide (Mg(NH) 2 ) 2 ), the molar ratio of lithium hydride (LiH) is 1:2, potassium silicon hydride (KSiH) 3 ) powder was added in an amount of 5 mol%. , then put the powder into the ball mill tank, add the grinding material (the ratio of ball to material is 50:1), vacuumize the ball mill tank, then fill it with a hydrogen pressure of 5MPa, and use a planetary ball mill for ball milling treatment (rotation speed 500rpm, ball mill Time 24h, alternately running clockwise and counterclockwise), after the ball milling is completed, take out the hydrogen storage material powder in the glove box to obtain Mg(NH) 2 ) 2 -2LiH-0.05KSiH 3 Composite hydrogen storage materials. Using the same conditions, the components are Mg(NH) 2 ) 2 -2LiH and Mg(NH 2 ) 2 -2LiH-0.05KH material served as a control. to Mg(NH 2 ) 2 -2LiH-0.05KSiH 3 and Mg(NH 2 ) 2 The two samples of -2LiH were tested for hydrogen relea...

Embodiment 2

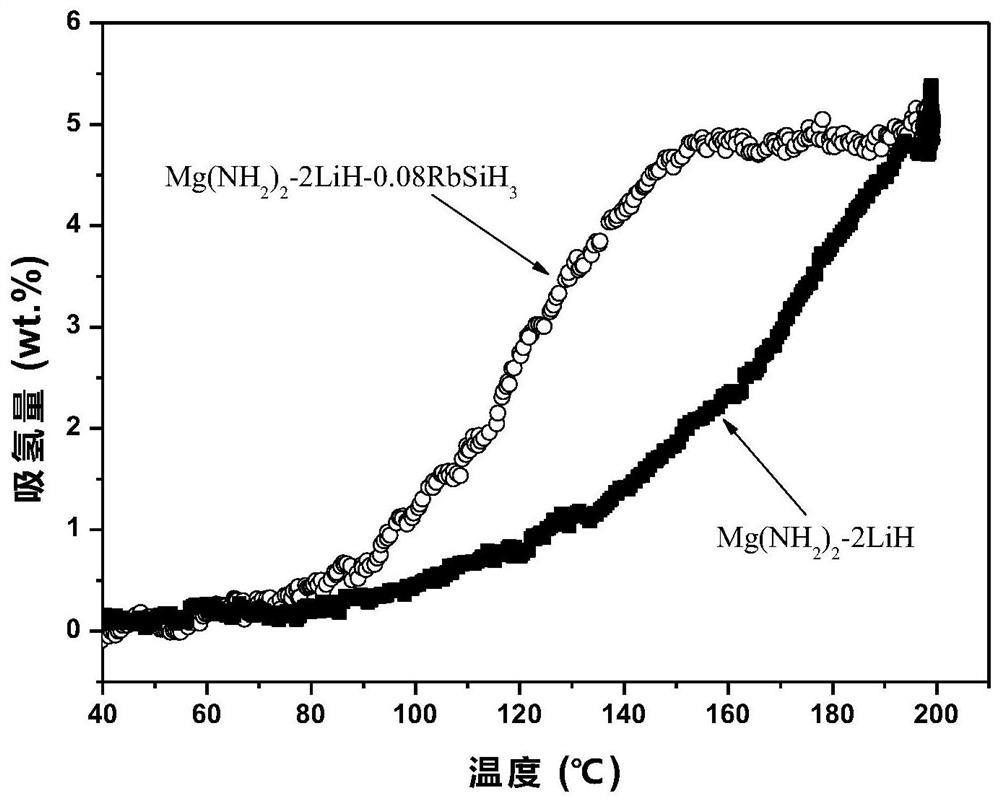

[0046] Samples were weighed in an argon atmosphere glove box with magnesium amide (Mg(NH) 2 ) 2 ), the molar ratio of lithium hydride (LiH) is 1:2, rubidium silicon hydride (RbSiH) 3 ) powder was added in an amount of 8 mol%. Then put the powder into the ball mill tank, add the grinding material (the ratio of ball to material is 60:1), vacuumize the ball mill tank, then fill in the hydrogen pressure of 4MPa, and carry out the ball milling treatment with a traveling planetary mill (rotation speed 400rpm, ball mill The time is 12h, clockwise and counterclockwise alternately), after the ball milling is completed, the hydrogen storage material powder is taken out in the glove box to obtain Mg(NH) 2 ) 2 -2LiH-0.08RbSiH 3 Hydrogen storage material; under the same conditions, Mg(NH) can be obtained 2 ) 2 The -2LiH material was used as a control. Depend on image 3 It can be seen that Mg(NH 2 ) 2 The -2LiH material begins to absorb hydrogen at about 100 °C, and can only abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com