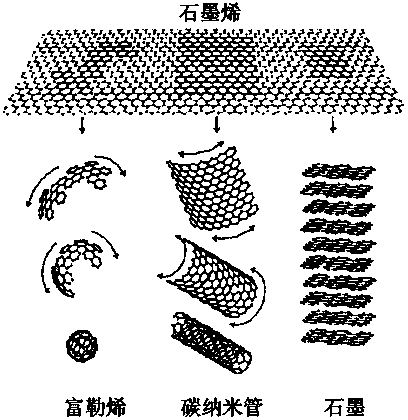

Multi-component active metal/graphene composite hydrogen storage material and preparation method thereof

A graphene composite and active metal technology, which is applied in fuel cells, electrical components, electrochemical generators, etc., can solve the problems of small specific surface area of graphene and limitation of graphene hydrogen storage capacity, so as to improve hydrogen storage capacity and cost Low, the effect of improving the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

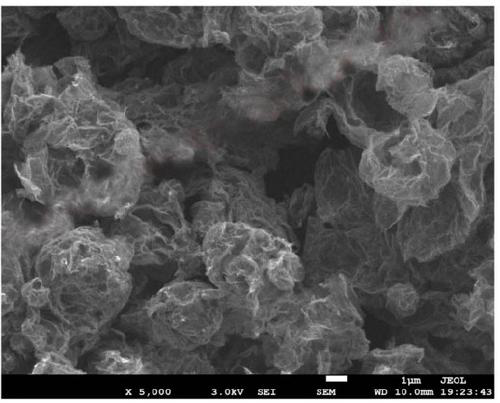

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation process of materials:

[0028] Step 1: Take 24mg of graphene oxide in a beaker, add 15mL of deionized water and sonicate for 18min to obtain a uniform light yellow-brown suspension, then place it in a water bath at 40°C for magnetic stirring, let it stand for 20h for ion exchange, and then take 600mg CaCl 2 ·6H 2 O and 60mgKOH were added to the solution and reacted for 30min in a nitrogen atmosphere.

[0029] Step 2: Add 240mg of Ru and Fe nanoparticles to the above solution, adjust the pH of the solution to 11 and react for 5h to obtain graphene oxide loaded Ca(OH) 2 , Ru and Fe suspensions, and then transfer the suspension to a polytetrafluoroethylene-lined reaction kettle to seal, put it in a drying oven at 170°C for 16h, filter the reaction product several times, wash and dry it at 240°C Calcined for 10 h to obtain graphene-supported Ru 2 o 3 , Fe 2 o 3 and CaO;

[0030] Step 3: Graphene supported Ru 2 o 3 , Fe 2 o 3 and CaO in Ar and H ...

Embodiment 2

[0034] (1) Preparation process of materials:

[0035]Step 1: Take 15 mg of graphene oxide in a beaker, add 30 mL of deionized water and sonicate for 5 minutes to obtain a uniform light yellow-brown suspension, then place it in a water bath at 30°C for magnetic stirring, and let it stand for 24 hours for ion exchange. 300mg MgSO 4 ·7H 2 O and 75mgKOH were added to the solution and reacted for 45min in a nitrogen atmosphere.

[0036] Step 2: Add 180 mg of Zn nanoparticles to the above solution, adjust the pH value of the solution to 9 and react for 5 hours to obtain graphene oxide loaded Mg(OH) 2 and Zn suspension, then transfer the suspension to a polytetrafluoroethylene-lined reactor and seal it, put it in a drying oven at 120°C for 25 hours, filter, wash and dry the reaction product several times, and then calcinate at 300°C for 6 hours , to obtain ZnO and MgO supported by graphene;

[0037] Step 3: Graphene supported ZnO and MgO in Ar and H 2 The reaction was carried ou...

Embodiment 3

[0041] (1) Preparation process of materials:

[0042] Step 1: Take 20mg of graphene oxide in a beaker, add 20mL of deionized water and sonicate for 15 minutes to obtain a uniform light yellow-brown suspension, then place it in a water bath at 25°C for magnetic stirring, let it stand for 12 hours for ion exchange, and then take 400mg AlCl 3 ·6H 2 O and 80mgNaOH were added to the solution, and reacted in a nitrogen atmosphere for 30min.

[0043] Step 2: Add 160 mg of Ni nanoparticles to the above solution, adjust the pH value of the solution to 10.5 and react for 3 hours to obtain graphene oxide supported Al(OH) 3 and Ni suspension, then transfer the suspension to a polytetrafluoroethylene-lined reactor and seal it, put it in a drying oven at 140°C for 18 hours, filter the reaction product several times, wash and dry it, and then calcinate at 280°C for 8 hours , to obtain graphene-supported NiO and Al 2 o 3 ;

[0044] Step 3: Graphene supported NiO and Al 2 o 3 In Ar and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com