A kind of high-strength siliceous brown glaze electric porcelain and its preparation method

A high-strength, siliceous technology, applied in the production of clay products, other household utensils, ceramic materials, etc., can solve the problems of difficult crushing of siliceous electric porcelain waste, few resources of high-alumina minerals, and low efficiency, and achieve enhanced fracture strength And flexural strength, improve density, improve the effect of bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

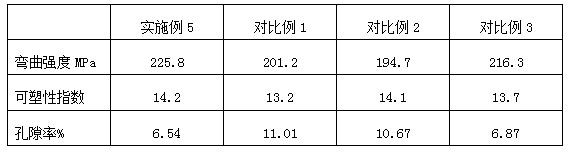

Examples

Embodiment 1

[0036] A high-strength electrical porcelain enamel siliceous brown, brown stock and includes enamel glaze, the blank is the percentage by weight of the raw material composition: 10% kaolin clay, wollastonite 30%, 10% Jiepai clay, silica powder, ceramic waste 10%, 20% glass powder, spodumene 10%, 3% yttria, the ceramic talc 3% 4% and fluorite. The brown glaze enamel is the percentage by weight of the raw material composition: 30% potassium feldspar powder, quartz powder 25%, 1.5% clay present blank, 15% calcite, talcum powder cooked 3.5%, 3% iron oxide, green complex 2.5 %, 4.5% manganese oxide and 15% Jiepai mud.

[0037] Method for preparing the high strength electrical porcelain enamel brown siliceous to: said blank material 12-18h are dried at 120 deg.] C, and then weighed in weight percent, uniformly mixed; the mixture, zirconia balls and water 3: 1: 1 As the mass ratio of a ball mill, a wet ball mill, a 100 mesh sieve, with the addition of iron in addition to iron equipment t...

Embodiment 2

[0039] A high-strength electrical porcelain enamel siliceous brown, brown stock and includes enamel glaze, the blank is the percentage by weight of the raw material composition: 20% kaolin, wollastonite 15%, 20% Jiepai clay, silica powder, ceramic waste 5%, 10% glass powder, spodumene 10%, 6% yttria, the ceramic talc 8% and 6% titanium dioxide. The brown glaze enamel is the percentage by weight of the raw material composition: 40% potassium feldspar powder, quartz powder 15%, 3% clay present blank, 14% calcite, talc cooked 2.5%, 2% iron oxide, green complex 3.5 %, 4% manganese oxide and 16% Jiepai mud.

[0040] Method for preparing the high-strength electrical porcelain enamel brown siliceous as: weighed amount of siliceous ceramic waste, coarsely crushed with a first jaw crusher, a hammer crusher and then finely divided, then coarsely ground, and then placed in a ball mill in wet grinding, the slurry was milled 200 mesh screen, filter press dewatering, and then placed in 120 ℃ 4-...

Embodiment 3

[0042] A high-strength electrical porcelain enamel siliceous brown, brown stock and includes enamel glaze, the blank is the percentage by weight of the raw material composition: 15% kaolin, wollastonite 20%, 15% Jiepai clay, silica powder, ceramic waste 8%, 15% glass powder, spodumene 15%, yttrium oxide 4%, 5% ceramic grade talc, titanium dioxide, 1% and 2% of phosphorus pentoxide. The brown glaze enamel is the percentage by weight of the raw material composition: 40% potassium feldspar powder, quartz powder, 23.5%, 2.5% clay present blank, 10% calcite, talc cooked 3%, 2.7% ferric oxide, complex Green 3 %, 3.3% manganese oxide and 12% Jiepai mud.

[0043] Method for preparing the high-strength electrical porcelain enamel brown siliceous as: weighed amount of siliceous ceramic waste, coarsely crushed with a first jaw crusher, a hammer crusher and then finely divided, then coarsely ground, and then placed in a ball mill in wet grinding, the slurry was milled 200 mesh screen, filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com