A kind of UV-cured electric leakage interruption protection coating, preparation method and application thereof

A technology for protecting coatings and ultraviolet light, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of affecting the insulation of battery packs, hollowing out of temperature changes, and weak bonding, etc. Production efficiency and environmental safety, good stability, and the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

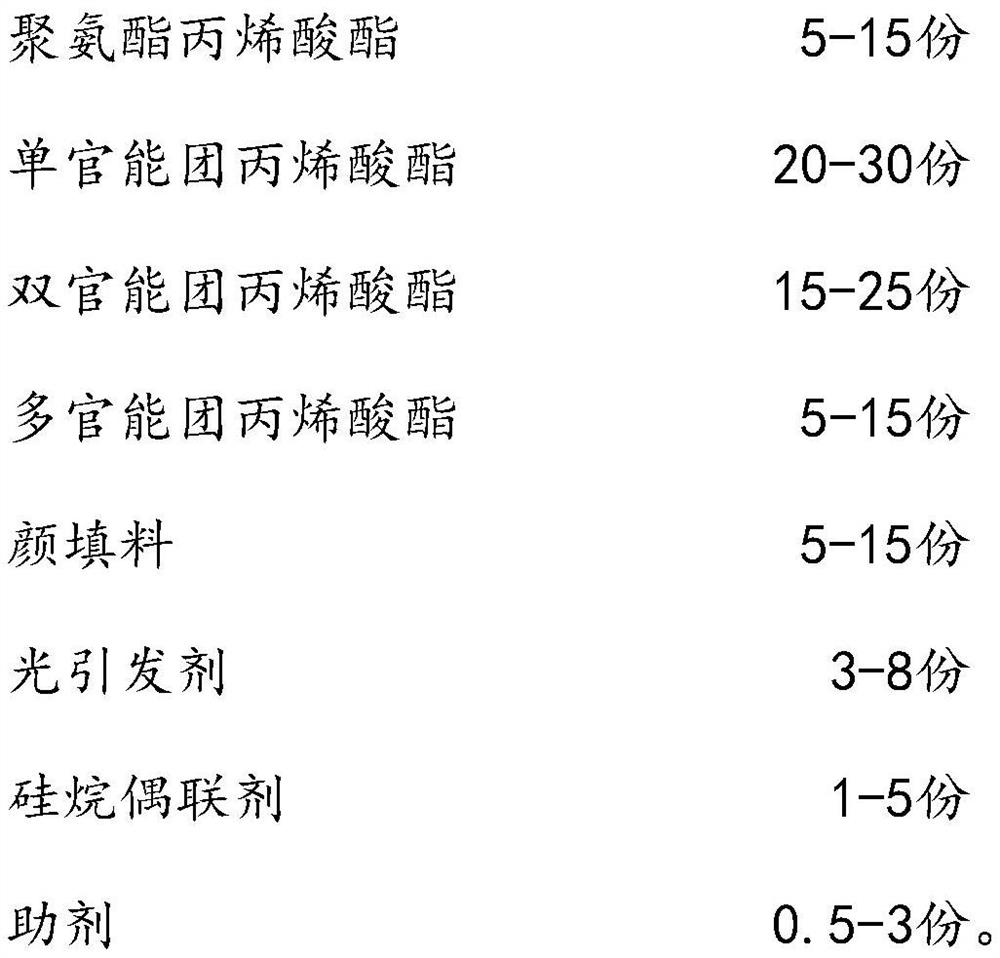

[0034] A kind of UV-curable electrical leakage protection coating, comprising the following components by weight: 10 parts of bifunctional fatty acid-modified bisphenol A epoxy acrylate, 5 parts of bifunctional polyHDI isocyanate acrylate, tetrahydrofuran acrylate 8 parts, 12 parts of isobornyl methacrylate, 15 parts of tricyclodecane dimethanol diacrylate, 10 parts of pentaerythritol triacrylate, 5 parts of pigments and fillers, 2-hydroxy-2-methyl-1-phenyl- 1 part of 1-acetone, 2 parts of (2,4,6-trimethylbenzoyl)diphenylphosphine oxide, 1 part of silane coupling agent KH-5501, 0.3 part of dispersant, 0.1 part of defoamer, leveling dose 0.2 servings.

[0035] A preparation method of an ultraviolet light-cured leakage electrical disconnection protective coating, comprising the following steps:

[0036] (1) Pre-mixing: add bifunctional fatty acid-modified bisphenol A epoxy acrylate, tetrahydrofuran acrylate, isobornyl methacrylate, dispersant and defoamer into the batching tank...

Embodiment 2

[0040] A kind of ultraviolet light-curing leakage circuit breaker protection coating, comprising the following components by weight: 15 parts of bifunctional fatty acid-modified bisphenol A epoxy acrylate, bifunctional polyH 12 10 parts of MDI isocyanate acrylate, 15 parts of tetrahydrofuran acrylate, 10 parts of N-hydroxyethylacrylamide, 20 parts of tricyclodecane dimethanol dimethyldiacrylate, tris(2-hydroxyethyl)isocyanurate 15 parts of acrylates, 10 parts of pigments and fillers, 3 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 2 (2,4,6-trimethylbenzoyl)diphenylphosphine oxide parts, silane coupling agent KH-5603 parts, dispersant 0.8 parts, defoamer 0.3 parts, leveling agent 0.5 parts.

[0041] A preparation method of an ultraviolet light-cured leakage electrical disconnection protective coating, comprising the following steps:

[0042] (1) Pre-mixing: add bifunctional fatty acid-modified bisphenol A epoxy acrylate, tetrahydrofuran acrylate, N-hydroxyethyl acrylamide,...

Embodiment 3

[0046] A kind of ultraviolet light-curing electrical leakage protection coating, comprising the following components by weight: 20 parts of bifunctional fatty acid-modified bisphenol A epoxy acrylate, 15 parts of bifunctional polyHDI isocyanate acrylate, methacrylic acid 15 parts of hydroxypropyl ester, 15 parts of tetrahydrofuran acrylate, 10 parts of tricyclodecane dimethanol diacrylate, 15 parts of tricyclodecane dimethanol dimethacrylate, 5 parts of propoxylated glycerol triacrylate, pigments and fillers 15 parts, 5 parts of 2-hydroxy-2-methyl-1-phenyl-1-propanone, 2.5 parts of (2,4,6-trimethylbenzoyl)diphenylphosphine oxide, silane coupling agent KH -5705 parts, 1.2 parts of dispersant, 0.8 part of defoamer, 1 part of leveling agent.

[0047] A preparation method of an ultraviolet light-cured leakage electrical disconnection protective coating, comprising the following steps:

[0048] (1) Pre-mixing: Add bifunctional fatty acid-modified bisphenol A epoxy acrylate, hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com