A low-temperature preparation method of refractory metal carbide solid solution powder

A metal carbide and refractory metal technology, applied in the field of high-temperature ceramic materials, can solve the problems of difficulty in industrialized production, environmental pollution of chlorides, difficult control of free carbon, etc., and achieves high purity, low equipment requirements, and easy industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

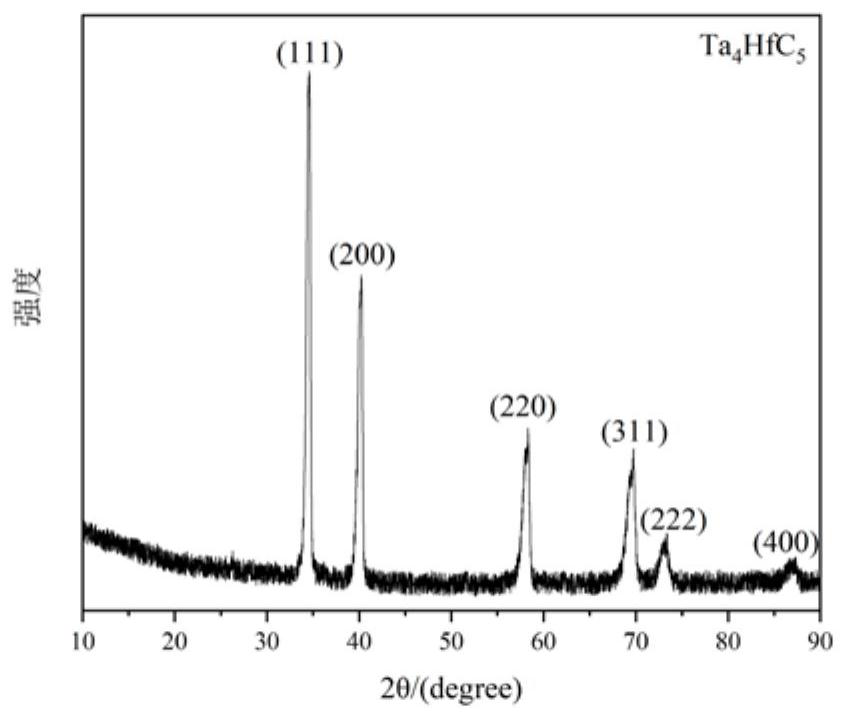

[0033] Mix pure HfC and TaC with a ball mill in a molar ratio of 1:4, then mix the mixed powder with metal calcium with a mass ratio of 1:0.5 and stir evenly, then heat to 1300°C for 4 hours under an argon atmosphere, and obtain after acid leaching. Ta 4 HfC5 powder. Detected by XRD, such as figure 1 shown, showing that the product is a single phase of pure Ta 4 HfC 5 .

Embodiment 2

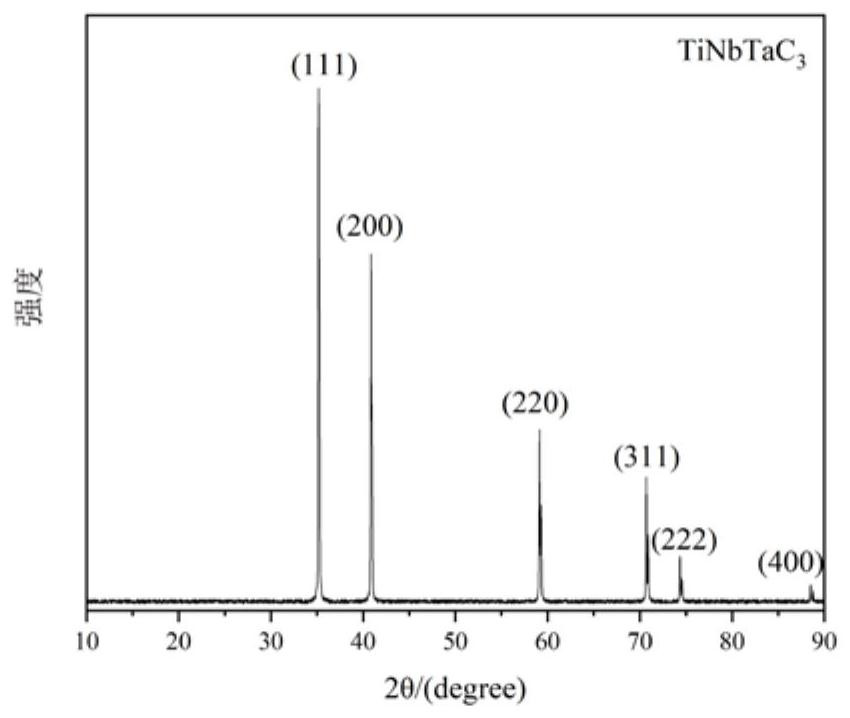

[0035] pure TiO 2 , Nb 2 O 5 , Ta 2 O 5 , C were mixed by ball milling in a molar ratio of 2:1:1:20, reacted in an argon atmosphere at 1600 ° C for 4 hours, and obtained the equimolar ratio composite powder of TiC, NbC, and TaC by carbothermal reduction. The composite powder was then mixed with metal calcium with a mass ratio of 1:0.6, then heated to 1200 °C for 10 hours in an argon atmosphere, and TiNbTaC was obtained after acid leaching. 3 powder. Detected by XRD, such as figure 2 shown, showing the product as pure TiNbTaC in a single phase 3 .

Embodiment 3

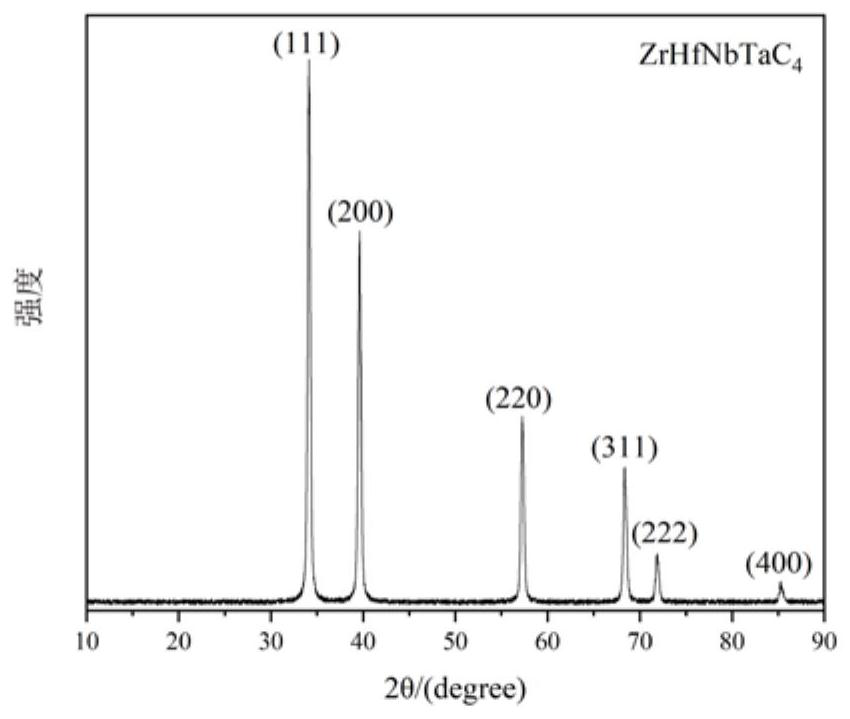

[0037] Mix pure ZrC, HfC, NbC and TaC with a ball mill in a molar ratio of 1:1:1:1, then mix the mixed powder with metal calcium in a mass ratio of 1:0.5 and stir evenly, then heat to 1400°C in an argon atmosphere After holding for 2 hours, ZrHfNbTaC was obtained after acid leaching 4 powder. Detected by XRD, such as image 3 shown, showing the product as pure ZrHfNbTaC in a single phase 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com