A temperature-resistant 1300°C frequency-selective wave-transparent/heat-insulating/stealth structure and its preparation method

A technology of frequency selection and wave penetration, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problem that the electrical performance of periodic pattern dimensional stability cannot be effectively guaranteed, does not have heat insulation function, and affects frequency Select surface electrical properties and other issues to avoid the application of organic solvents and lead glass, facilitate large-scale engineering applications, and achieve large-scale engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

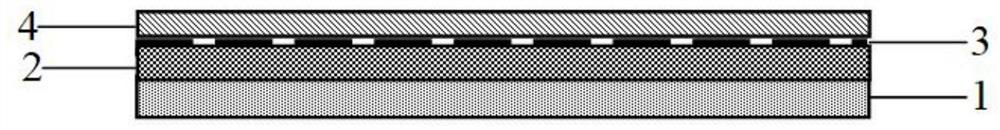

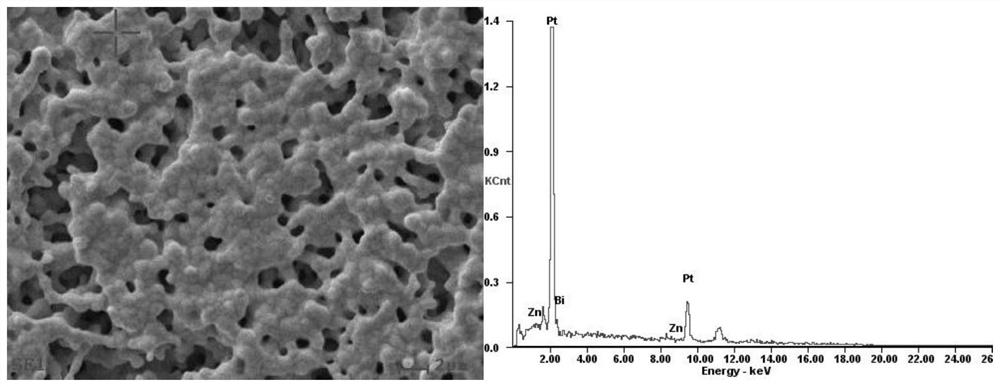

[0051] A frequency-selective wave-transparent / heat-insulating / stealth structure with a temperature resistance of 1300°C such as figure 1 As shown, the outer surface is defined by the incident direction of electromagnetic waves, and includes a heat insulating layer 1, a wave-transmitting layer 2, a frequency selective layer 3, and a ceramic protective layer 4 in sequence from the inside to the outside. The heat insulation layer is mullite fiber felt reinforced silica airgel composite material, the microwave dielectric constant of mullite fiber felt reinforced silica airgel composite material is 1.35, the dielectric loss is 0.008, and the density is 0.4g / cm 3 , the thermal conductivity at room temperature is 0.004W / m·K, and after hydrophobic treatment, the mass moisture absorption rate is less than 1%. The wave-transparent layer is made of quartz fiber needle-punched parts reinforced silica composite material, the size of defects such as surface holes is not greater than 0.5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com