Dolomite magnesium cement inner and outer wall fireproof decoration board and preparation method thereof

A manufacturing method and technology of magnesium cement are applied in the field of dolomite magnesium cement interior and exterior wall fireproof decorative panels and their manufacturing fields, which can solve the problems of high raw material cost and difficult promotion of magnesite fireproof decorative panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

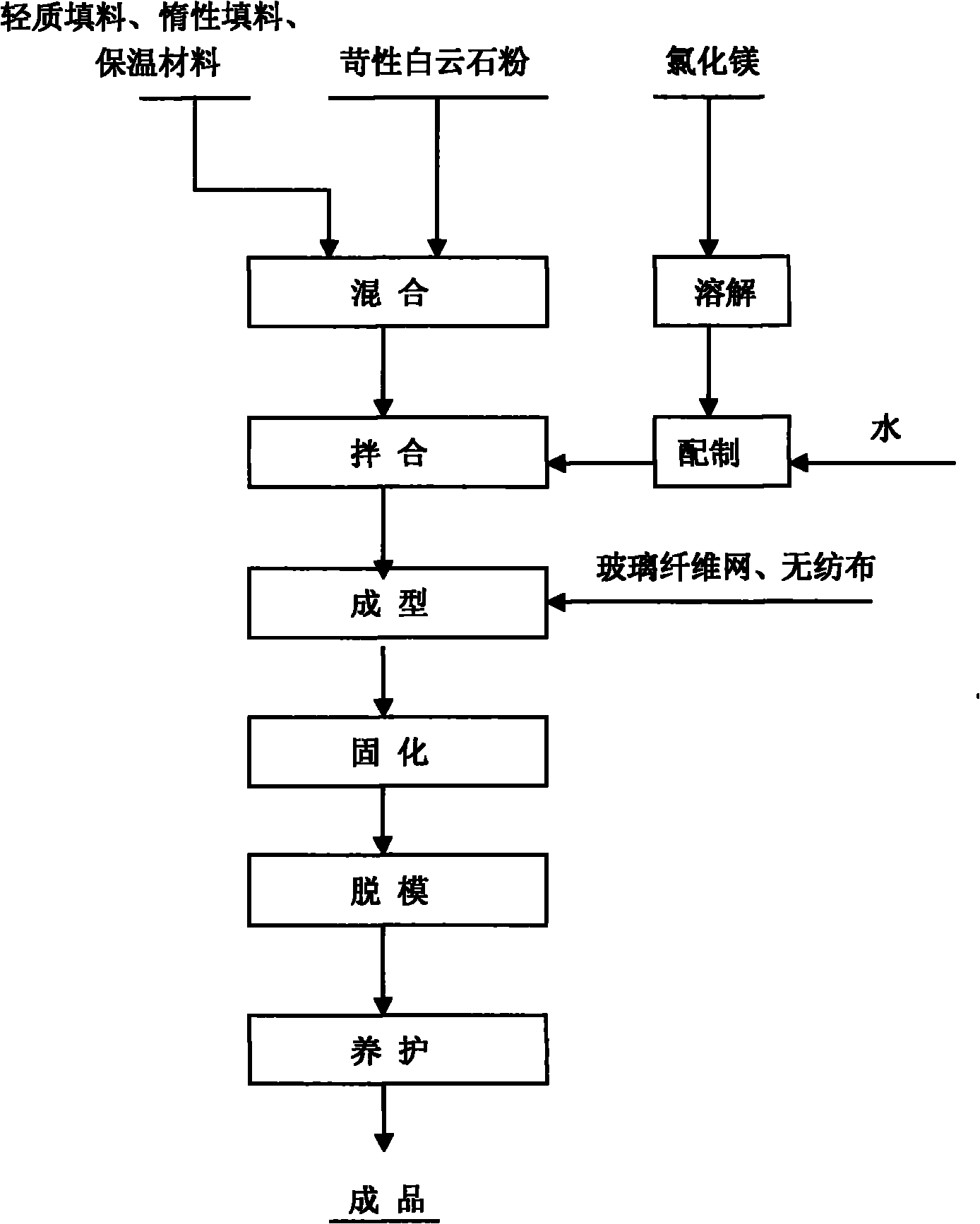

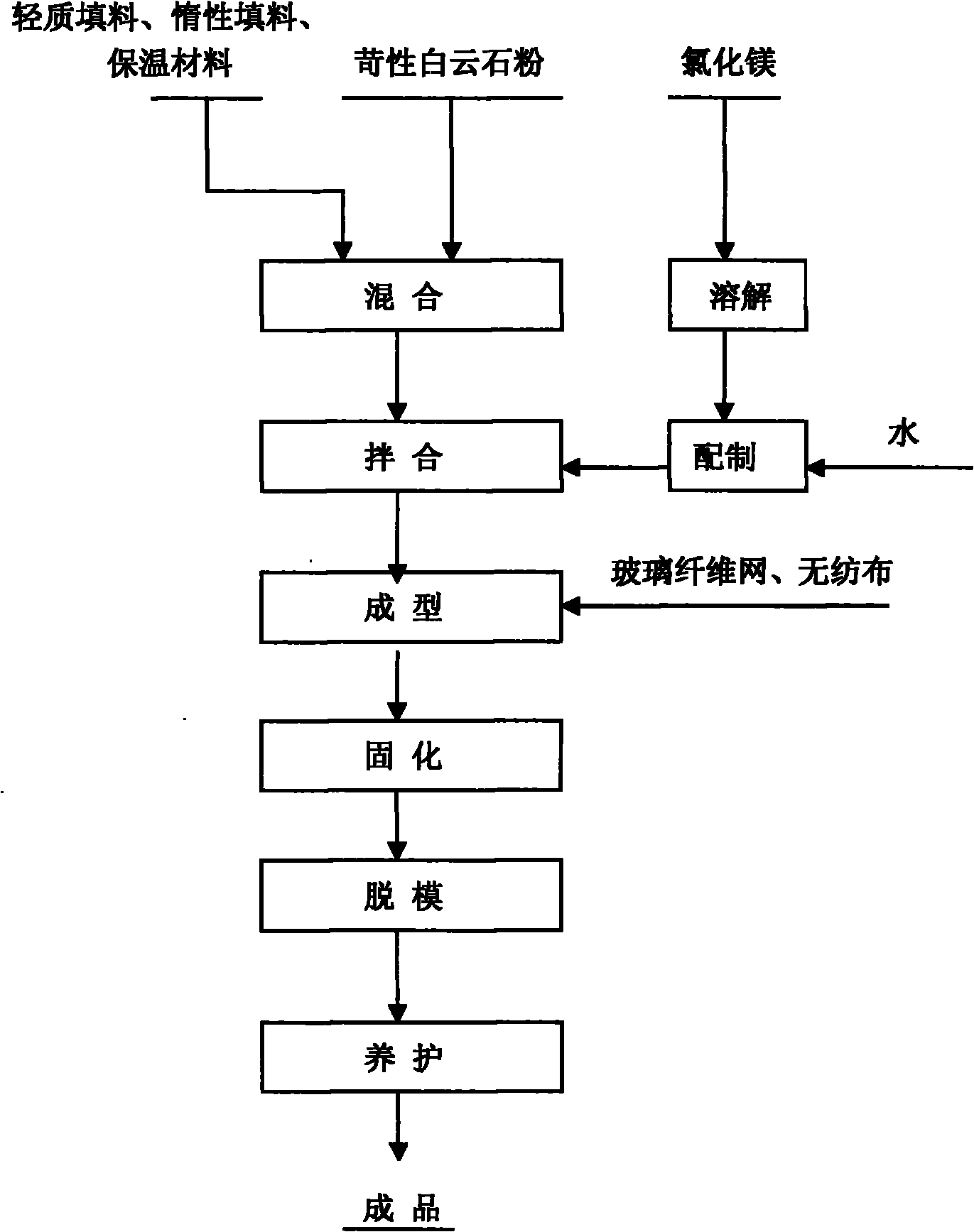

Method used

Image

Examples

Embodiment 1

[0005] Embodiment 1. A dolomite magnesium cement interior wall fire-proof decorative panel and its manufacture method, get caustic dolomite powder 10kg, magnesium chloride 1.2kg, sawdust 1kg, fly ash 0.5kg, expanded perlite 0.5kg, water 4.4kg will magnesium chloride and water to make a solution, the solution and other materials are stirred evenly in a mixer to make a slurry, the second layer of glass fiber mesh is laid in the interior wall decorative panel mold, and the non-woven fabric is laid on the back, and the slurry is injected. Under the condition of 10°C, molded and cured for 18 hours, demoulded, and cured at 10°C and relative air humidity less than 80% after demoulding, it will be finished product after 28 days.

[0006] The main technical indicators of the finished product are as follows:

[0007] Flexural strength: 25MPa, impact strength: 5kj / m 2 , horizontal combustion S: 0, vertical combustion S: 0, bulk density: 1.60g / cm 3 , Shrinkage rate: 0.3%, water resistan...

Embodiment 2

[0008] Embodiment 2: A kind of dolomite magnesium cement exterior wall fireproof decorative board and its manufacture method, take caustic dolomite powder 10kg, magnesium chloride 4kg, straw 6kg, talcum powder 3kg, expanded vermiculite 3kg, water 12kg, prepare magnesium chloride and water into a solution, the solution and other materials are stirred evenly in a mixer to make a slurry, and the second layer of glass fiber mesh is laid in the mold of the exterior wall decorative panel, and the non-woven fabric is laid on the back, and the slurry is injected. After molded and cured for 24 hours, it is demoulded, and after demoulding, it is cured at 30°C and the relative air humidity is less than 80% for 28 days before it becomes a finished product.

[0009] Its main technical indicators are as follows:

[0010] Flexural strength: 15MPa, impact strength: 3.0kj / m 2 , horizontal combustion S: 0, vertical combustion S: 0, bulk density: 1.10g / cm 3 , Dry shrinkage rate: 0.4%, water re...

Embodiment 3

[0011] Embodiment 3: a kind of dolomite magnesium cement exterior wall fireproof decorative board and its manufacture method, get caustic dolomite powder 10kg, magnesium chloride 3kg, sawdust and straw (shell) mixture 3kg, slag powder 1.5kg, polystyrene 2kg, water 8kg ,, magnesium chloride and water are prepared into a solution, and the solution and other materials are stirred evenly in a mixer to make a slurry. The second layer of glass fiber mesh is laid in the mold of the exterior wall decorative panel, and the back is laid with non-woven fabric. The slurry is molded and cured at 20°C for 20 hours and then released from the mold. After demoulding, it is cured at 25°C and the relative air humidity is less than 80% for 28 days before it becomes a finished product.

[0012] Its main technical indicators are as follows:

[0013] Flexural strength: 20MPa, impact strength: 4.8kj / m 2 , horizontal combustion S: 0, vertical combustion S: 0, bulk density: 1.40g / cm 3 , Shrinkage rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com