Excess material recycling and reusing device of polyester fiber screen

A polyester fiber and waste material technology, which is applied in the field of waste material recovery and reuse devices for polyester fiber screens, can solve problems such as waste of resources, short service life, and abnormal production, so as to save resources and costs, and avoid partial Defects, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

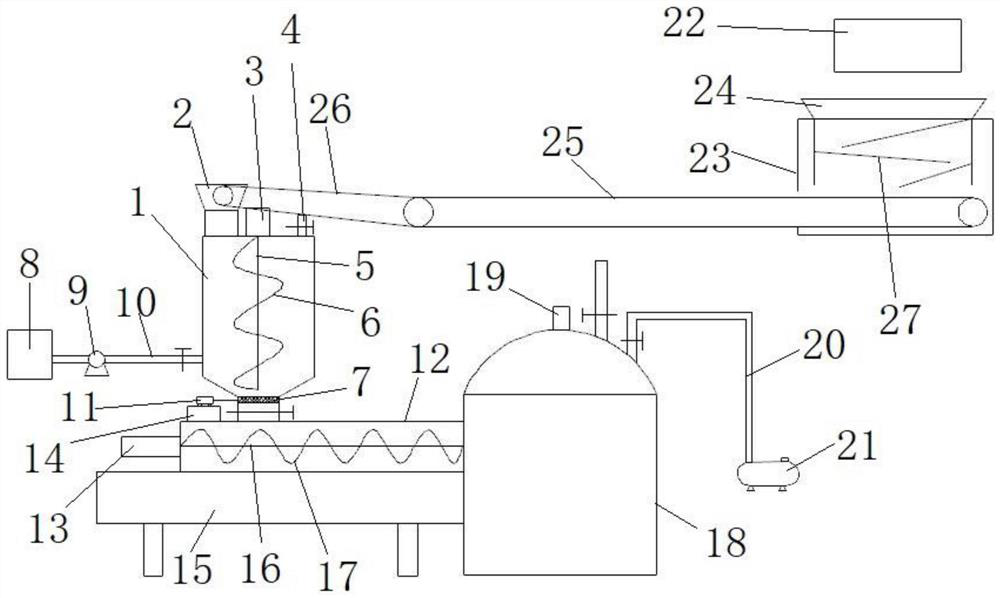

[0026] Such as figure 1 and figure 2 As shown, in this embodiment, the collection mechanism includes a collection box 23 and a feed hopper 24 arranged on the collection box 23 , and the feed hopper 24 is located below the polyester fiber screen punching device 22 . Specifically, the collection box is arranged below the working end surface of the working platform where the opening device is located, and one or more feeding hoppers are arranged on the collecting box. The size of the top opening of the feeding hopper should be slightly larger than the end surface of the working platform, so as It is ensured that when the remaining material after punching falls from the working platform, it can all fall into the feeding hopper, and then guide to the inside of the collection box for collection. In order to prevent other impurities from entering the hopper under non-working conditions, an openable and closable sealing cover or filter screen can be installed at the opening of the f...

Embodiment 2

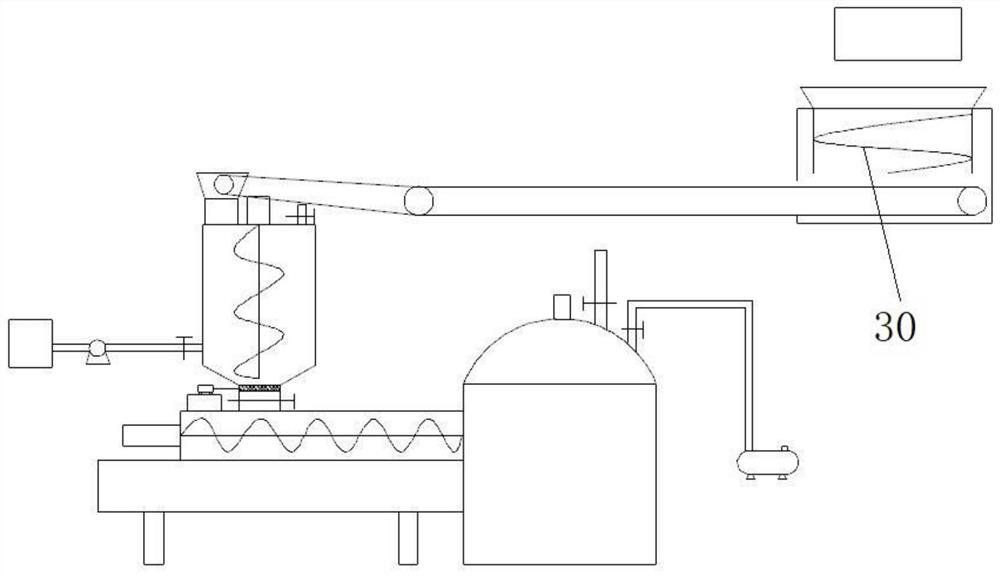

[0038] The difference between this embodiment and embodiment 1 is that, as image 3 As shown, the buffer passage includes a passage body and a spiral slideway 30 disposed in the passageway body, and the bottom outlet of the spiral slideway 30 points to the conveying direction of the first belt. Under the action of the buffer force of the spiral slideway, it avoids the large impact damage caused by the direct free fall of the remaining material, and plays the role of auxiliary anti-slip.

[0039] Further, such as Figure 4 As shown, the collection box 23 is provided with a first baffle 31 and a second baffle, and the first baffle and the second baffle are respectively located on both sides of the first belt 25 of the first belt 25 conveying mechanism. The first baffle and the second baffle can adopt a baffle structure with the same structure and size, the length direction of the baffle is the same as the conveying direction of the first belt, and the distance between the two b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com