Ultrasonic-assisted eutectic reaction brazing method for dissimilar metal

A technology of eutectic reaction and brazing method, used in metal processing equipment, welding equipment, manufacturing tools, etc., to achieve the effects of low energy consumption, improved oxidation resistance, and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

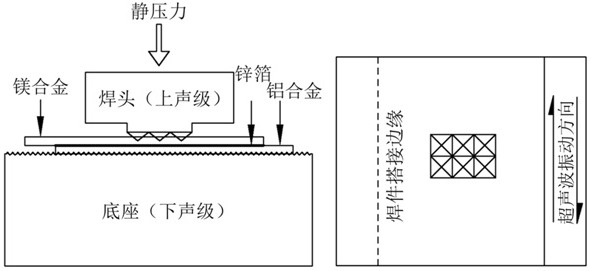

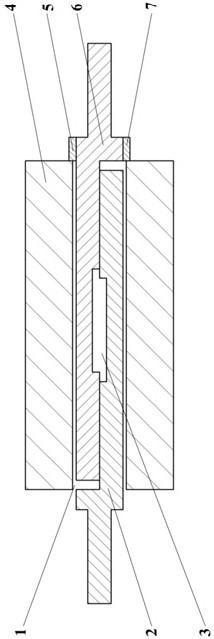

Method used

Image

Examples

Embodiment 1

[0058] Influence of Welding Energy on Joint Shear Strength

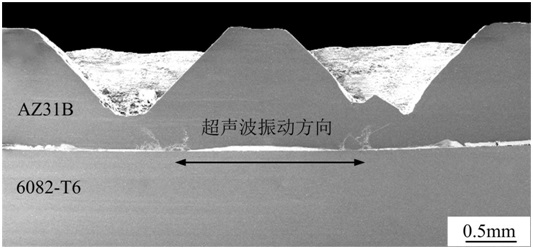

[0059] Cut the 0.1mm thick aluminum alloy and magnesium alloy into a square of 25mm×25mm, cut the 50μm thick zinc foil into a rectangle of 20mm×25mm, and then cut some of the cut aluminum alloy and magnesium alloy and zinc foil for pre-welding pretreatment and workpiece assembly. The rated power is 3000W, the working frequency is 20.11KHz, the power supply voltage is 200-240V, and the welding energy varies within the range of 200-2500J, which are respectively taken as 200J, 500J, 800J, 1100J, 1400J, 1700J, 2000J, 2500J for ultrasonic welding of Mg / Zn foil / Al dissimilar alloys.

[0060] The results show that with the increase of welding energy, the shear strength of the joint shows a trend of first increasing and then decreasing. When the welding energy is 1700J, the shear strength of the joint reaches the maximum.

Embodiment 2

[0062] Influence of Welding Amplitude on Shear Strength of Joint

[0063] Cut the 0.1mm thick aluminum alloy and magnesium alloy into a square of 25mm×25mm, cut the 50μm thick zinc foil into a rectangle of 20mm×25mm, and then cut some of the cut aluminum alloy and magnesium alloy and zinc foil for pre-welding pretreatment and workpiece assembly. The rated power is 3000W, the working frequency is 20.11KHz, the power supply voltage is 200-240V, and the welding amplitude changes within the range of 60%-100%, which are respectively taken as 65%, 75%, and 85%, 95%, ultrasonic welding of Mg / Zn foil / Al dissimilar alloys.

[0064] The results show that as the welding amplitude increases, the shear strength of the joint shows a gradual increase trend, and when the welding amplitude is 95%, the joint shear strength reaches the maximum.

Embodiment 3

[0066] Influence of Welding Static Pressure on Joint Shear Strength

[0067] Through the research of Examples 1 and 2, it can be known that the shear strength of ultrasonic welding of Mg / Zn foil / Al is the maximum when the welding energy is 1700J and the welding amplitude is 95%. Under the conditions of welding energy of 1700J and welding amplitude of 95%, the effect of welding static pressure on joint shear strength was studied. Cut the 0.1mm thick aluminum alloy and magnesium alloy into a square of 25mm×25mm, cut the 50μm thick zinc foil into a rectangle of 20mm×25mm, and then cut some of the cut aluminum alloy and magnesium alloy and zinc foil for pre-welding pretreatment and workpiece assembly. The rated power is 3000W, the working frequency is 20.11KHz, the power supply voltage is 200-240V, and the welding static pressure varies within the range of 0-0.65MPa, which are respectively taken as 0.2MPa, 0.3MPa, 0.4MPa, 0.5MPa, for ultrasonic welding of Mg / Zn foil / Al dissimilar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com