Reinforced unit cell structure, preparation method and application thereof and sandwich panel

A sandwich panel and unit cell technology, applied in the field of reinforced materials, can solve the problems of incompetent anti-explosion, anti-penetration, impact resistance, and inability to meet safety standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the reinforced unit cell structure described in the above technical solution, comprising the following steps:

[0047] Fix the welding torch on the spindle of the CNC machine tool, and input the finished product parameters in the CNC machine tool;

[0048] Start the welding machine and use the welding torch to preheat the substrate;

[0049] Start the wire feeder and send the wire to the bottom of the welding torch;

[0050] The welding torch heats the wire material, and the resulting melt falls onto the substrate to form a molten pool, and printing starts to obtain the reinforced unit cell structure.

[0051] In the present invention, the welding torch is preferably covered with a metal ring; a threaded hole is opened in the metal ring, and matching screws in the threaded hole fix the welding torch on the spindle of the numerically controlled machine tool.

[0052] In the present invention, the printing param...

Embodiment 1

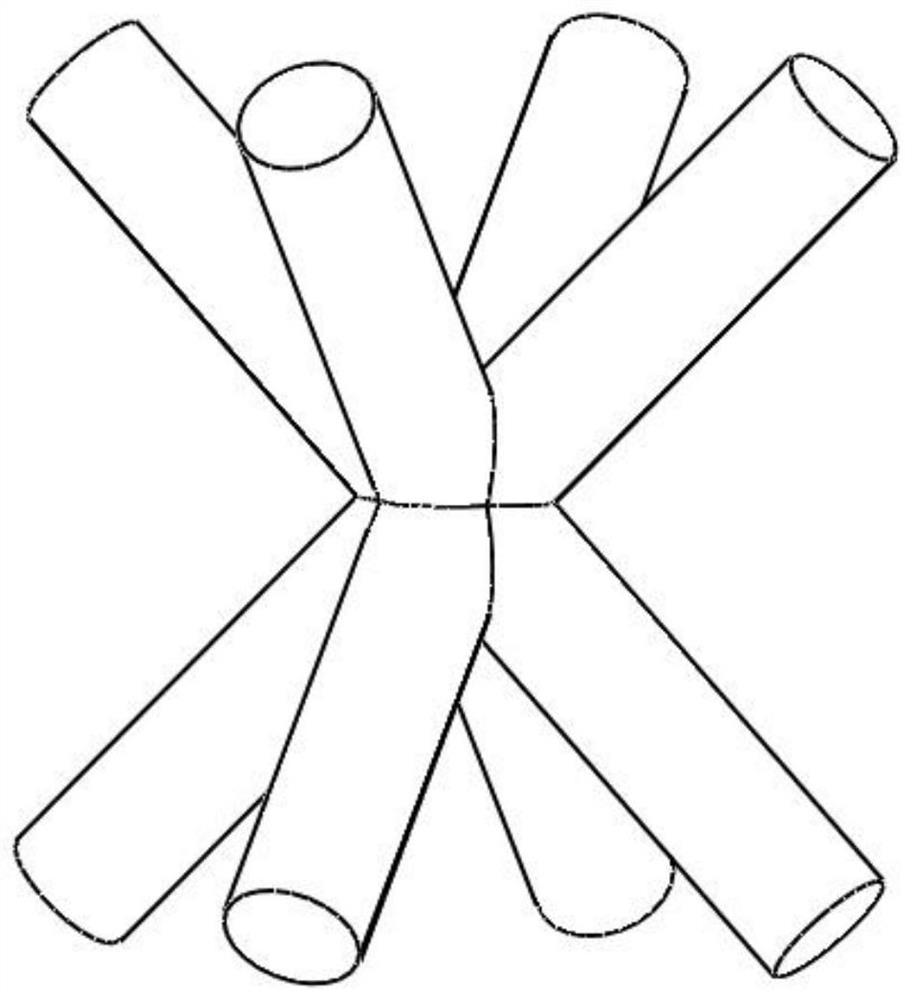

[0078] A sandwich panel: the upper and lower panels are 1mm thick TC4 boards; the sandwich layer is a single-layer reinforced unit cell structure, with 5 layers in the X direction, 1 layer in the Y direction, and 5 layers in the Z direction, with a total of 25 unit cells. The length, width and height of each unit cell are 7mm, the length of the bar is 4.95mm, and the radius of the bar is 0.3mm; the total thickness of the whole assembly is 9mm; the material of the sandwich layer is TC4.

[0079] Sandwich panels are printed using laser selective melting technology.

[0080] Test of sandwich panels against vertical 90° frontal high-speed collision:

[0081] The penetrating object is a tungsten steel ball with a diameter of 10mm, and its incident velocity is 350m / s (simulating the exit velocity of ordinary pistols and submachine gun projectiles), ignoring the influence of gravity.

[0082] The resulting speed-time graph of the steel ball is shown in Figure 9 shown. From Figu...

Embodiment 2

[0084] A sandwich panel: the upper and lower panels are 2mm thick TC4 boards; the sandwich layer is a single-layer reinforced unit cell structure, with 5 layers in the X direction, 1 layer in the Y direction, and 5 layers in the Z direction, with a total of 25 unit cells. The length, width and height of each unit cell are 7mm, the length of the bar is 4.95mm, and the radius of the bar is 0.3mm; the total thickness of the whole sandwich panel is 9mm; the material of the sandwich layer is TC4.

[0085] Sandwich panels are printed using laser selective melting technology.

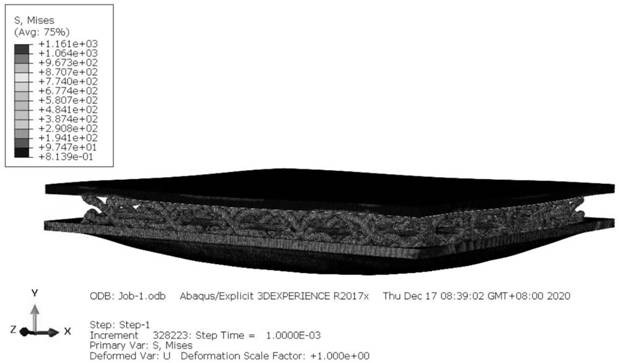

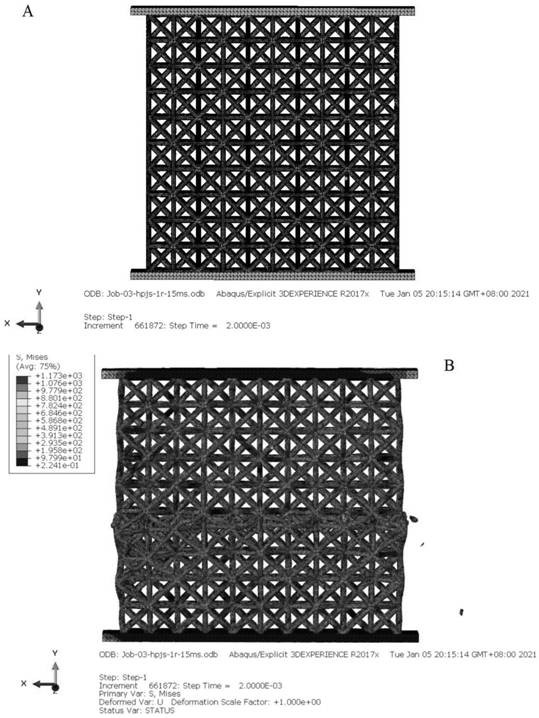

[0086] Numerical Simulation of TNT Explosion

[0087] Place 5g of TNT at a position 40mm from the center of the panel on the sandwich panel for explosion, the effect picture is as follows Figure 10 shown. From Figure 10 It can be seen that each unit cell is squeezed, and the overall structure is evenly stressed, which can effectively absorb energy.

[0088] Figure 11 It is the energy absorption-time cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com