A heat treatment method for preparing nanocrystalline magnetic core

A heat treatment method and nanocrystalline technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of long process cycle, high annealing equipment, and complexity, and achieve short heat treatment time, uniform stress distribution, and improved uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

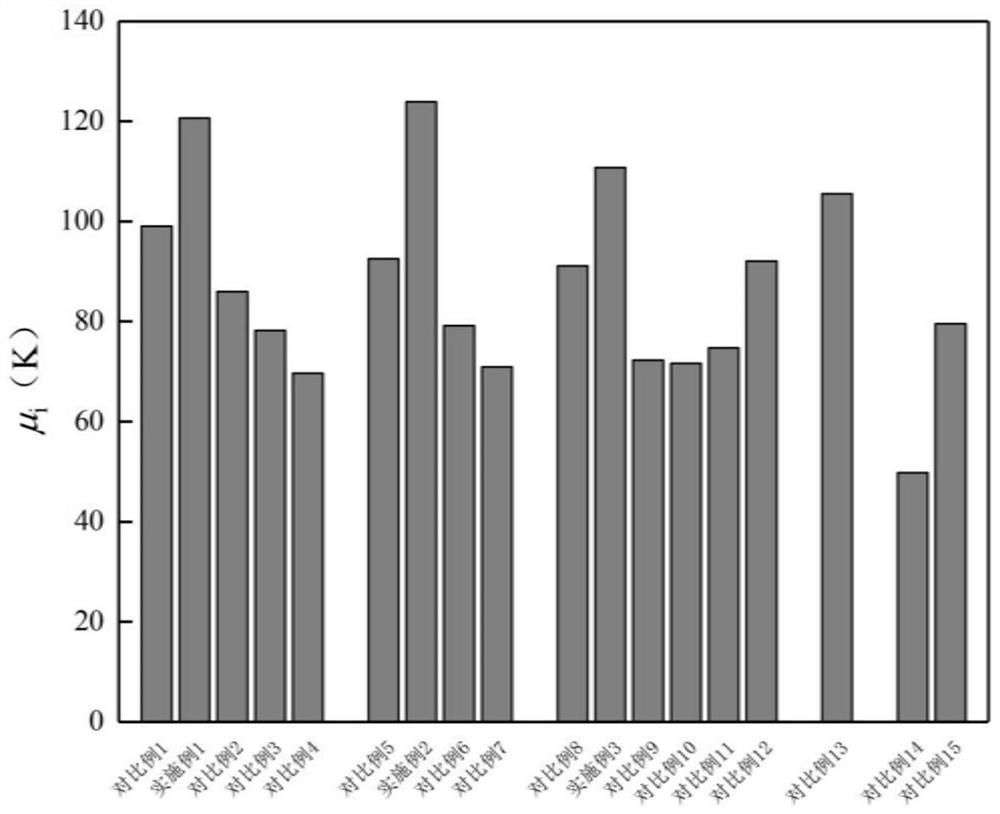

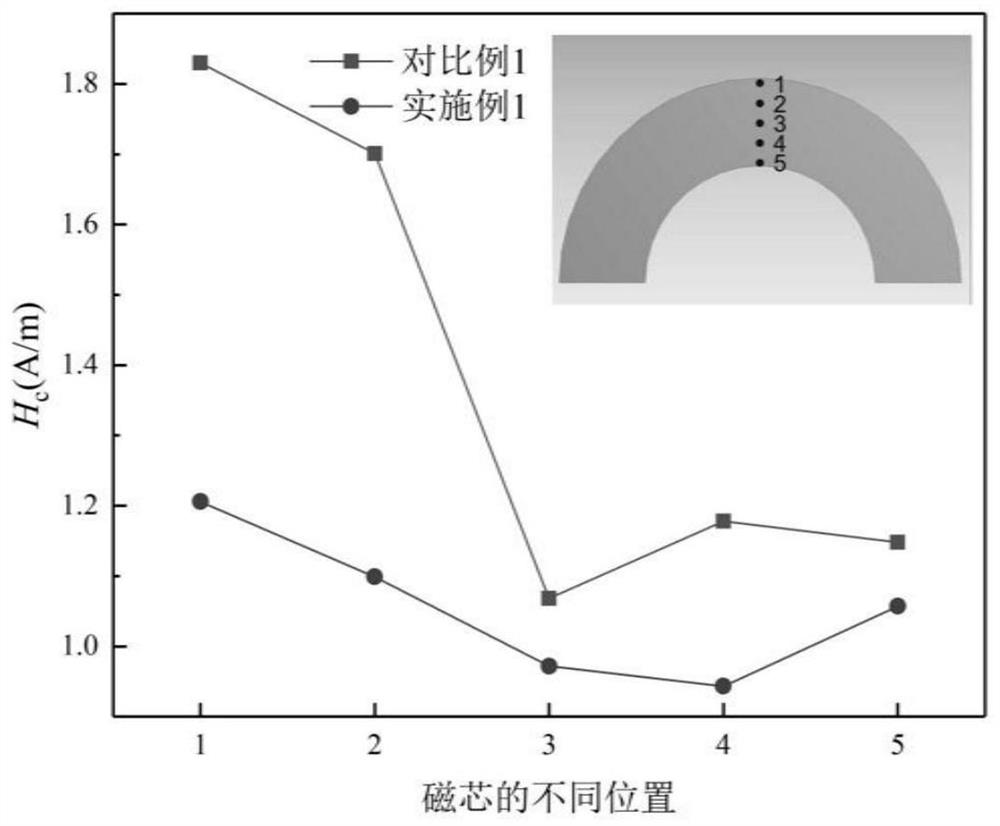

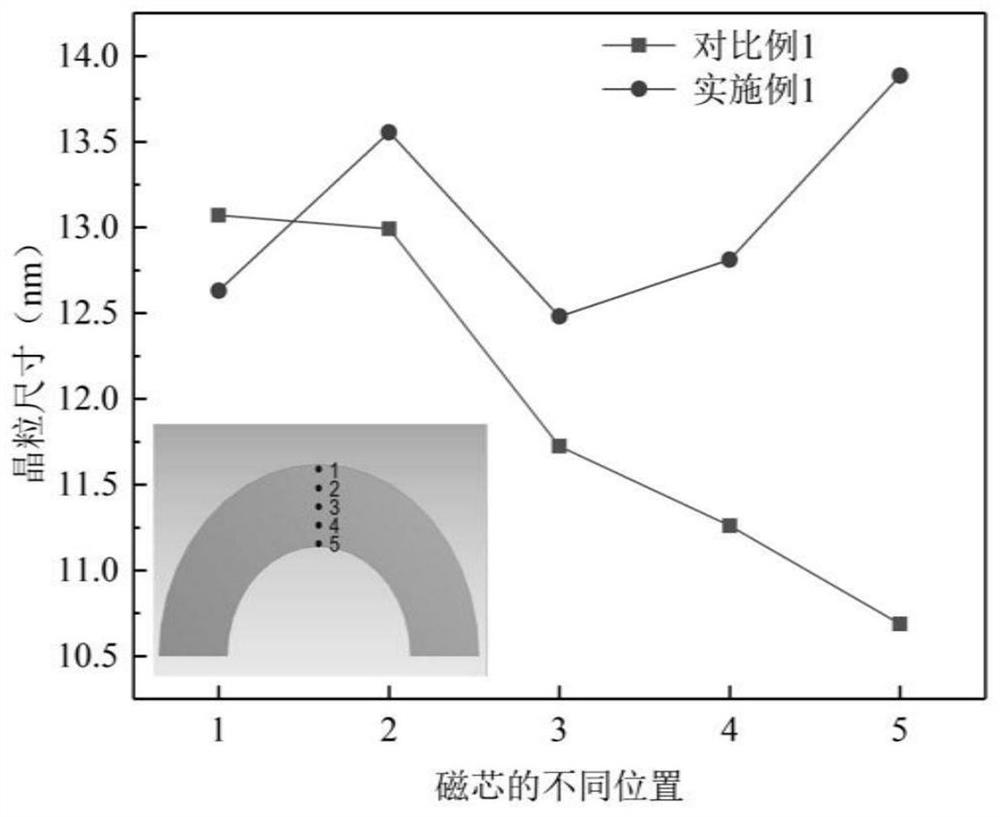

Embodiment 1

[0030] A heat treatment method for preparing a nanocrystalline magnetic core, comprising the following steps:

[0031] (1) Select the grade as 1K107 (T x 798K) quenched strip Fe 73.5 Cu 1 Nb 3 Si 13.5 B 9 , the strip with a width of 5mm is wound into a ring core with an outer diameter of 14mm and an inner diameter of 10mm by a winding machine, and the thickness of the ring core is 2mm;

[0032] (2) Selecting a copper strip with a thickness equal to that of the iron-based amorphous alloy strip and having a thickness of 0.1 mm is wound into a circular copper strip roll, and the outer end is fixed by spot welding. The number of layers of the copper strip roll It is 5 layers, the thickness ratio of the corresponding annular magnetic core to the copper coil is 4:1, the layers of the copper coil are in close contact with each other, and the distance between the inner side of the copper coil and the outer side of the magnetic core is 1 mm; then placed in the quartz In the tube,...

Embodiment 2

[0034] A kind of heat treatment method for preparing nanocrystalline magnetic core is as described in embodiment 1, and difference is that the thickness ratio of annular magnetic core and copper tape volume is 10:3, and annealing temperature is 785K (T x -13K), the holding time is 7min.

Embodiment 3

[0036] A kind of heat treatment method for preparing nanocrystalline magnetic core is as described in embodiment 1, and difference is that the thickness ratio of annular magnetic core and copper tape volume is 2.5:1, and annealing temperature is 773K (T x -25K), the holding time is 20min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com