Hollow microsphere/Ni-Fe-P/Cu composite coating and preparation method thereof

A technology of hollow microspheres and composite coatings, applied in coatings, liquid chemical plating, metal material coating processes, etc., can solve problems such as easy sedimentation and high density, and achieve difficult deposition, high conductivity, and wide frequency range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

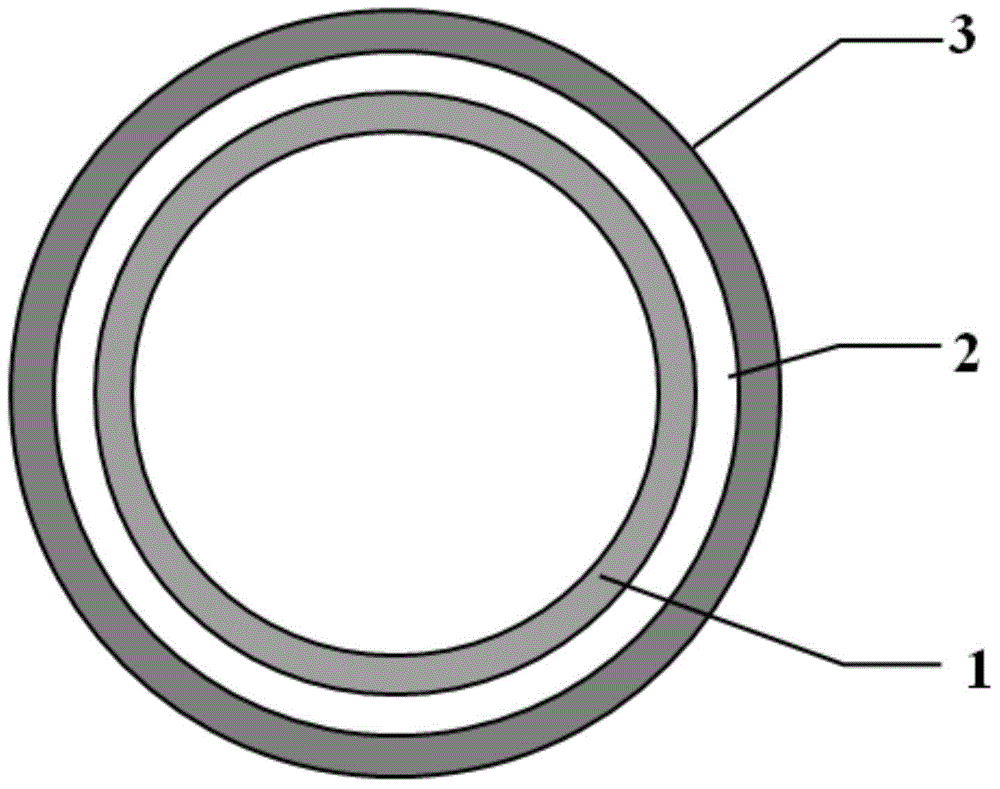

[0026] Specific embodiment one: a kind of hollow microsphere / Ni-Fe-P / Cu composite coating of this embodiment is composed of from inside to outside: matrix hollow microsphere, amorphous Ni-Fe-P soft magnetic coating and nano-Cu Conductive plating.

[0027] The hollow microsphere composite coating of the present embodiment forms three interfaces from the inside to the outside: the semi-vacuum space in the cavity and the hollow microsphere wall, the hollow microsphere wall and the Ni-Fe-P coating and the Ni-Fe-P plating and Cu plating. The hollow microsphere / Ni-Fe-P / Cu composite coating has the characteristics of the two single coatings, and at the same time increases the interface, which is beneficial to broadband shielding and improves the electromagnetic shielding performance of the material.

specific Embodiment approach 2

[0028] Specific embodiment two: the preparation method of a kind of hollow microsphere / Ni-Fe-P / Cu composite coating of the present embodiment is to carry out according to the following steps:

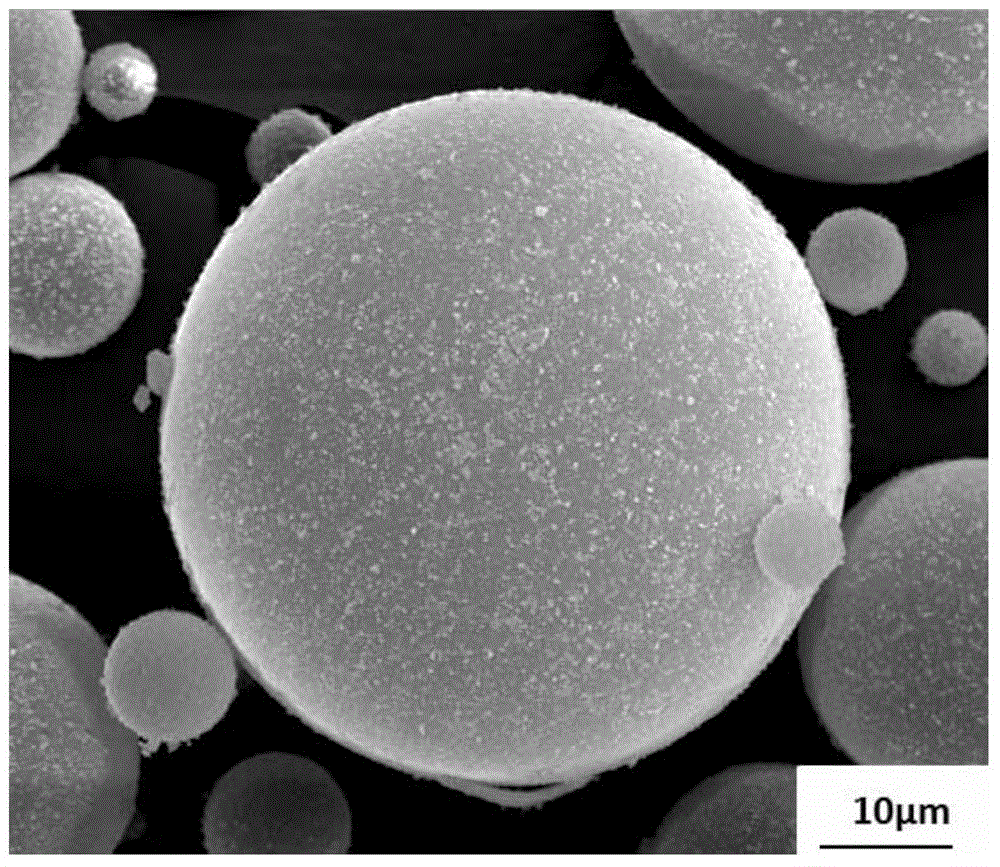

[0029] 1. Cleaning: with NaOH and Na 2 CO 3 Prepare alkaline cleaning solution for raw materials, the concentration of NaOH in the prepared alkaline cleaning solution is 10-30g / L, NaOH 2 CO 3 The concentration is 15-40g / L, the hollow microspheres with a particle size of 1-100μm are added to the above alkaline cleaning solution, and the temperature is 20-40°C for magnetic stirring or mechanical stirring for 20-50min, and the Floating glass beads on the upper layer, and then wash with deionized water or distilled water for 1 to 3 times until the solution is neutral, and finally dry in a drying oven at a temperature of 40 to 70°C for 30 to 70 minutes to obtain hollow microspheres with a clean and rough surface. beads;

[0030] 2. Sensitization: use concentrated HCl with a mass concentr...

specific Embodiment approach 3

[0040] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the concentration of NaOH in the alkaline cleaning solution after preparing in the step 1 is 20g / L, NaOH 2 CO 3 The concentration is 30g / L. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com