High magnetostriction iron based amorphous alloy and preparation thereof

A technology of iron-based amorphous alloy and stretching, which is applied in the field of high magnetostrictive iron-based amorphous alloy and its preparation, to achieve the effects of strong amorphous forming ability, high thermal stability, and high magnetostriction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

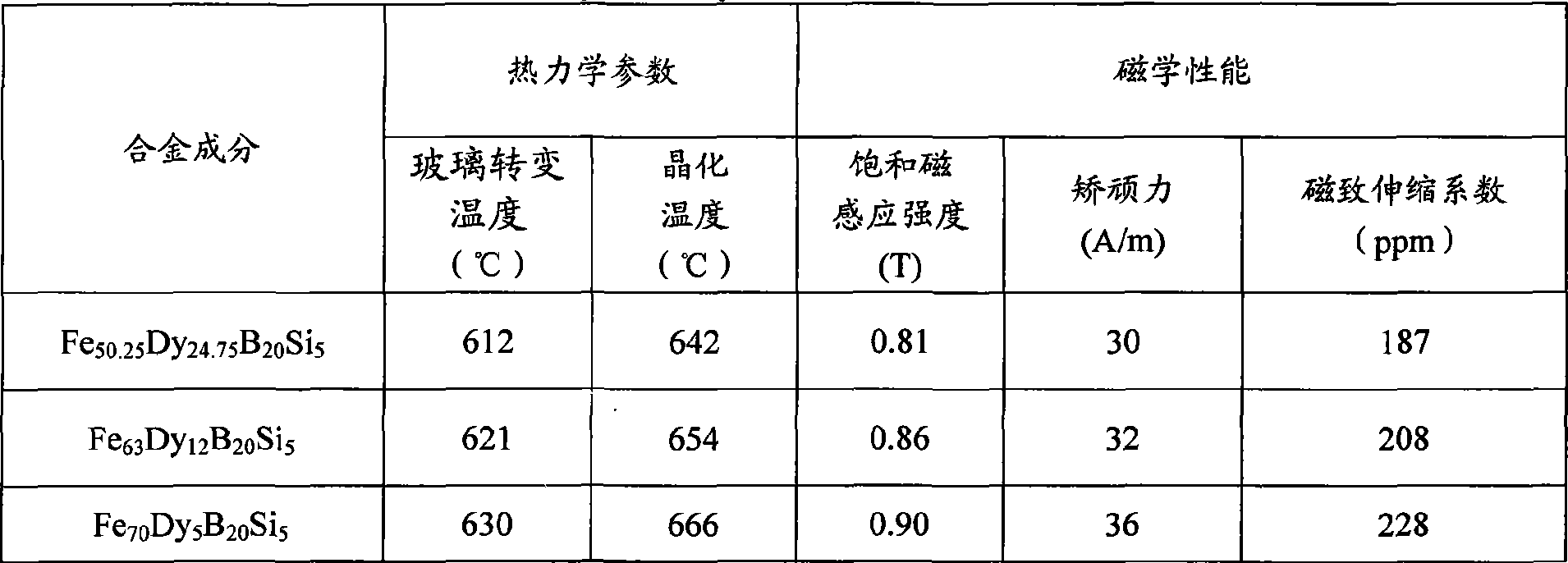

[0018] Embodiment 1: prepare Fe 50.25 Dy 24.75 B 20 Si 5 Amorphous Alloy Ribbon

[0019] In this embodiment, a single-roller strip method is used to prepare Fe with a thickness of 20 μm-60 μm and a width of 1.5mm-2.5mm. 50.25 Dy 24.75 B 20 Si 5 Amorphous alloy thin strips.

[0020] Step 1: By atomic percent Fe 50.25 Dy 24.75 B 20 Si 5 Weigh Fe with a purity of 99.8%, Si with a purity of 99.9%, Dy and FeB alloys with a purity of 99.9%, put the target composition raw materials into a vacuum induction magnetic levitation melting furnace, and use electromagnetic fields and eddy currents after vacuuming The effect makes the alloy suspend, heat and melt, and the alloy is repeatedly smelted 5 times to obtain Fe with uniform composition. 50.25 Dy 24.75 B 20 Si 5 master alloy.

[0021] Step 2: Take the Fe obtained in step 1 50.25 Dy 24.75 B 20 Si 5 The master alloy ingot is broken into small pieces after descaling, and ultrasonically cleaned in alcohol.

[0022] St...

Embodiment 2

[0028] Embodiment 2: prepare Fe 63 Dy 12 B 20 Si 5 Amorphous Alloy Ribbon

[0029] In this embodiment, a single-roller strip method is used to prepare Fe with a thickness of 20 μm-60 μm and a width of 1.5mm-2.5mm. 63 Dy 12 B 20 Si 5 Amorphous alloy thin strips.

[0030] Step 1: By atomic percent Fe 63 Dy 12 B 20 Si 5 Weigh Fe with a purity of 99.8%, Si with a purity of 99.9%, Dy and FeB alloys with a purity of 99.9%, put the target composition raw materials into a vacuum induction magnetic levitation melting furnace, and use electromagnetic fields and eddy currents after vacuuming The effect makes the alloy suspend, heat and melt, and the alloy is repeatedly smelted 3 times to obtain Fe with uniform composition.63 Dy 12 B 20 Si 5 master alloy.

[0031] Step 2: Take the Fe obtained in step 1 63 Dy 12 B 20 Si 5 The master alloy ingot was broken into small pieces and ultrasonically cleaned in alcohol.

[0032] Step 3: Using the Fe obtained in Step 2 63 Dy 12...

Embodiment 3

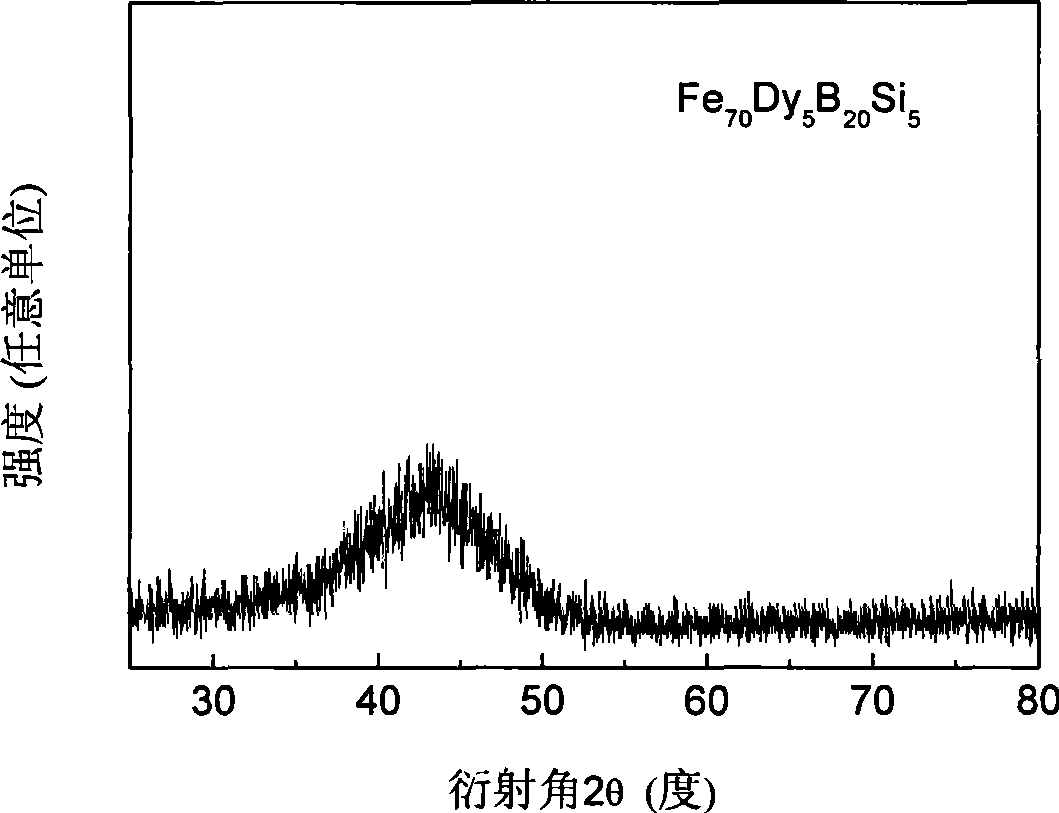

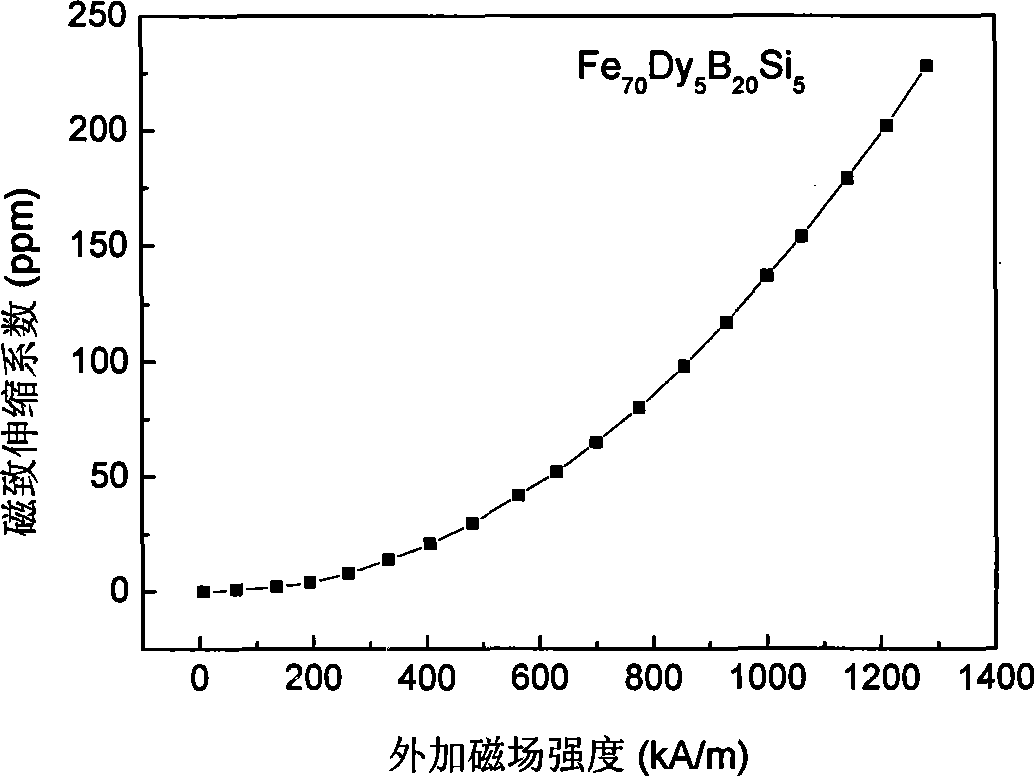

[0038] Embodiment 3: prepare Fe 70 Dy 5 B 20 Si 5 Amorphous Alloy Ribbon

[0039] In this embodiment, a single-roller strip method is used to prepare Fe with a thickness of 20 μm-60 μm and a width of 1.5mm-2.5mm. 70 Dy 5 B 20 Si 5 Amorphous alloy thin strips.

[0040] Step 1: By atomic percent Fe 70 Dy 5 B 20 Si 5 Weigh Fe with a purity of 99.8%, Si with a purity of 99.9%, Dy and FeB alloys with a purity of 99.9%, put the target composition raw materials into a vacuum induction magnetic levitation melting furnace, and use electromagnetic fields and eddy currents after vacuuming The effect makes the alloy suspend, heat and melt, and the alloy is repeatedly smelted 4 times to obtain Fe with uniform composition. 70 Dy 5 B 20 Si 5 master alloy.

[0041] Step 2: Take the Fe obtained in step 1 70 Dy 5 B 20 Si 5 The master alloy ingot was broken into small pieces and ultrasonically cleaned in alcohol.

[0042] Step 3: Using the Fe obtained in Step 2 70 Dy 5 B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com