Novel polycrystal magnetostriction material based on morphotropic phase boundary and preparation method of novel polycrystal magnetostriction material based on morphotropic phase boundary

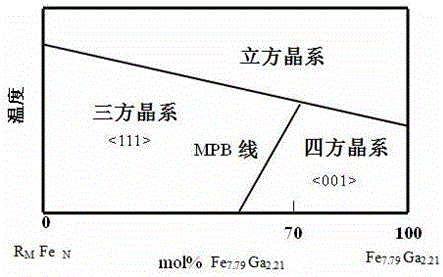

A magnetostrictive material and quasi-isomorphic phase boundary technology, applied in the field of new materials, can solve the problems of low magnetostriction coefficient of FeGa alloy, achieve the effects of promoting application and development, improving mechanical properties, and reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

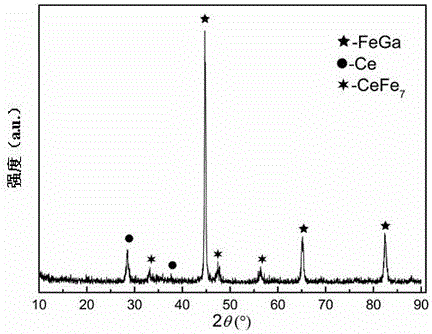

Embodiment 1

[0032] The composition is (Fe 7.79 Ga 2.21 ) 50 (CeFe 7 ) 50 alloy. The purity of raw materials is higher than 99.99%, and the total weight of smelting target is 1500g. Calculate the atomic percentages of Fe, Ga, and Ce respectively, and convert them into weight percentages. The weights of the three components are 1107.02g, 183.95g, and 209.03g, respectively. In order to shorten the smelting time and reduce the burning loss of elements, raw materials, especially pure iron rods, should be processed into short rods.

[0033] First vacuum the vacuum induction melting furnace to 3×10 -2 Pa, then turn on the electricity to heat up, fill in 99.999% high-purity argon to 0.6 standard atmosphere, wash the furnace twice, when the temperature rises to 1350°C, fill in argon to 1.05 standard atmosphere, and then increase the power to melt as soon as possible . After 2 minutes of melting the charge, cast it into a polycrystalline rod of Φ18×100mm. The polycrystalline rod is kept at...

Embodiment 2

[0036] The composition is (Fe 7.79 Ga 2.21 ) 60 (CeFe 7 ) 40 alloy. The purity of raw materials is higher than 99.99%, and the total weight of smelting target is 1500g. Calculate the atomic percentages of Fe, Ga, and Ce respectively, and convert them into weight percentages. Only the weights of the three components are 1107.40g, 223.38g, and 169.22g, respectively.

[0037] First vacuum the vacuum induction melting furnace to 2×10 -2 Pa, then turn on the electricity to heat up, fill in 99.999% high-purity argon to 0.7 standard atmosphere, wash the furnace twice, when the temperature rises to 1300°C, fill in argon to 1.1 standard atmosphere, and then increase the power to melt as soon as possible . After 3 minutes of melting the charge, cast it into a polycrystalline rod of Φ18×100mm. The polycrystalline rod is kept at 1000°C for 1.5h in a vacuum sintering furnace, then cooled to 700°C with the furnace for 5h, and after two-stage heat treatment, the polycrystalline magne...

Embodiment 3

[0039] The composition is (Fe 7.79 Ga 2.21 ) 70 (CeFe 7 ) 30 alloy. The purity of raw materials is higher than 99.99%, and the total weight of smelting target is 1500g. Calculate the atomic percentages of Fe, Ga, and Ce respectively, and convert them into weight percentages. Only the weights of the three components are 1107.79g, 263.76g, and 128.45g, respectively.

[0040] First vacuum the vacuum induction melting furnace to 2~5×10 -2 Pa, then turn on the electricity to heat up, fill in 99.999% high-purity argon to 0.8 standard atmosphere, wash the furnace twice, when the temperature rises to 1400°C, fill in argon to 1 standard atmosphere, and then increase the power to melt as soon as possible . After 2.5 minutes of melting the charge, it is cast into a polycrystalline rod of Φ18×100mm. After the polycrystalline rod is kept at 1000°C for 1 hour in a vacuum sintering furnace, it is cooled to 900°C with the furnace and held for 3 hours. After two-stage heat treatment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetostriction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com