Straw hydrothermal carbon-based coal-like briquette fuel for combustion and preparation method thereof

A technology of molding fuel and hydrothermal carbon, which is applied in the direction of fuel, waste fuel, biofuel, etc., can solve the problems of waste of water resources, discharge, easy looseness and stability, etc., to reduce waste water treatment costs, improve overall efficiency, energy The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

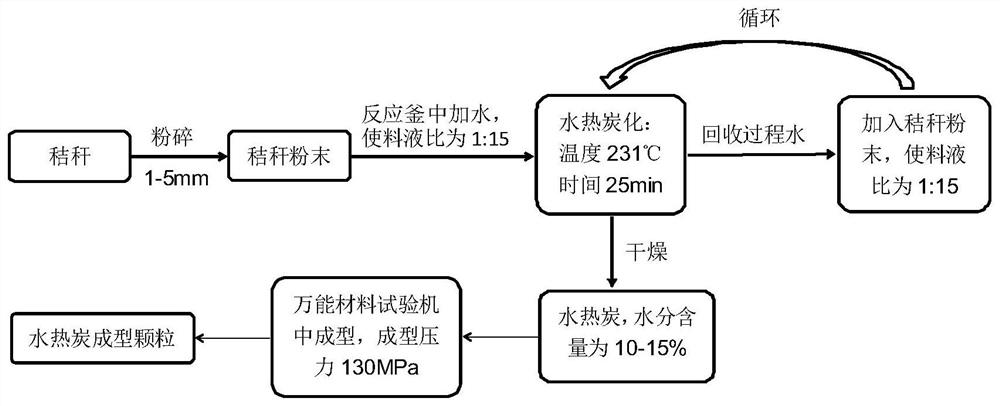

[0028] A method for preparing "coal-like" briquette fuel based on straw hydrothermal charcoal for combustion, comprising the following steps:

[0029] The straw is pulverized and subjected to hydrothermal carbonization. The temperature of the hydrothermal carbonization is 220-240° C., the hydrothermal carbonization time is 20-30 minutes, and the water is circulated 2-3 times during the hydrothermal carbonization process to obtain biochar.

[0030] In some embodiments, the straw is wheat straw, corn straw, rice straw and cotton straw.

[0031] In some embodiments, the particle size of the crushed straw is 0.5-5mm.

[0032] Further, during the hydrothermal carbonization process, the ratio of solid to liquid is 1:12-17, preferably 1:15.

[0033] In some embodiments, the temperature of hydrothermal carbonization is 230-235° C., and the time of hydrothermal carbonization is 22-27 minutes.

[0034] Further, the temperature of hydrothermal carbonization is 231° C., and the time of ...

Embodiment

[0041] A method for preparing a "coal-like" briquette fuel based on straw hydrothermal charcoal for combustion, comprising the following steps:

[0042] Use straw as raw material, cut it to 30-35cm, and crush it to 1-5mm with a high-speed pulverizer; mix the crushed straw and water evenly at a ratio of 1:15, and carry out hydrothermal carbonization reaction in a high-pressure reactor ;Set the hydrothermal carbonization temperature to 231°C, and the hydrothermal carbonization time to 25 minutes, using automatic pressure; after the hydrothermal carbonization experiment, recover the liquid by-products, and carry out the hydrothermal carbonization reaction again according to the above method, with a total of 2 or 3 cycles can;

[0043] After the reactor is cooled to room temperature, the hydrothermal charcoal and liquid by-products are separated by vacuum filtration, and the hydrothermal charcoal is dried in an oven at 60°C until the moisture content is 10-15%; the universal mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com