Removable glue and preparation method thereof

A technology of glue and epoxy resin, which is applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of low mechanical strength and easy cracks in the bonding layer, and overcome the problems of low mechanical strength, easy peeling, The effect of excellent adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

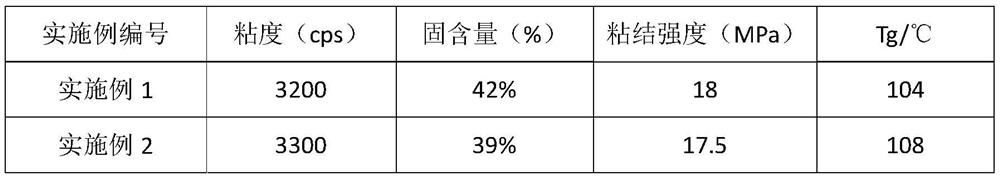

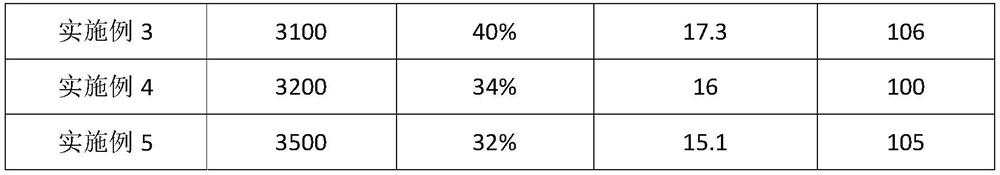

Examples

preparation example Construction

[0044] Another aspect of the present invention also provides a preparation method of removable glue, comprising the following steps:

[0045] (1) Slowly add the polymer into the organic solvent, while stirring until uniformly dispersed;

[0046] (2) Add curing agent, plasticizer, defoamer, coupling agent and stir evenly, seal and let stand for 3-6h;

[0047] (3) Open the lid and stir until the mixture is fully dissolved and becomes transparent, then seal and let stand for 12-36 hours.

[0048] When the composition of the glue does not contain defoaming agent or coupling agent, this operation is correspondingly omitted in the preparation step.

Embodiment 1

[0051] On the one hand, this embodiment provides a kind of removable glue, which includes the following components in parts by weight:

[0052] 30 parts of bisphenol A epoxy resin, 15 parts of polyvinyl butyral resin, 15 parts of hydroxypropyl methacrylate, 5 parts of 2-methylimidazole, 4 parts of tributyl citrate, EX-1710 defoamer 1 part, 5 parts of vinyltriethoxysilane, 15 parts of methylcyclohexane, 10 parts of isopropanol.

[0053] The bisphenol A epoxy resin was purchased from Changsha Fudakang Chemical Materials.

[0054] The polyvinyl butyral resin was purchased from Tianyuan New Material Company.

[0055] Another aspect of this embodiment provides a method for preparing removable glue, comprising the following steps:

[0056] (1) Bisphenol A epoxy resin, polyvinyl butyral resin, and hydroxypropyl methacrylate are slowly added to the organic solvent methylcyclohexane and isopropanol mixture, and stirred until uniformly dispersed;

[0057] (2) Add 2-methylimidazole, t...

Embodiment 2

[0060] On the one hand, this embodiment provides a kind of removable glue, which includes the following components in parts by weight:

[0061] 32 parts of bisphenol F epoxy resin, 16 parts of polyvinyl butyral resin, 16 parts of hydroxypropyl methacrylate, 4 parts of 2-imidazole, 5 parts of acetyl tributyl citrate, 1 part of EX-1710 defoamer Parts, 6 parts of vinyltrimethoxysilane, 12 parts of ethylcyclohexane, 8 parts of propanol.

[0062] The bisphenol F epoxy resin was purchased from Henan Water Ring Company, and the model was NPEF-170.

[0063] The polyvinyl butyral resin was purchased from Tianyuan New Material Company.

[0064] Another aspect of this embodiment provides a method for preparing removable glue, comprising the following steps:

[0065] (1) Slowly add bisphenol F epoxy resin, polyvinyl butyral resin, and hydroxypropyl methacrylate into the organic solvent ethylcyclohexane and propanol mixture, and stir until uniformly dispersed;

[0066] (2) Add imidazole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com