Preparation method of high-strength anti-aging anti-clogging reinforced composite geotextile

A composite geotextile, high-strength technology, applied in chemical instruments and methods, soil protection, sea area engineering, etc., can solve problems such as silting, poor anti-ultraviolet aging performance, inelastic self-adaptive deformation ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

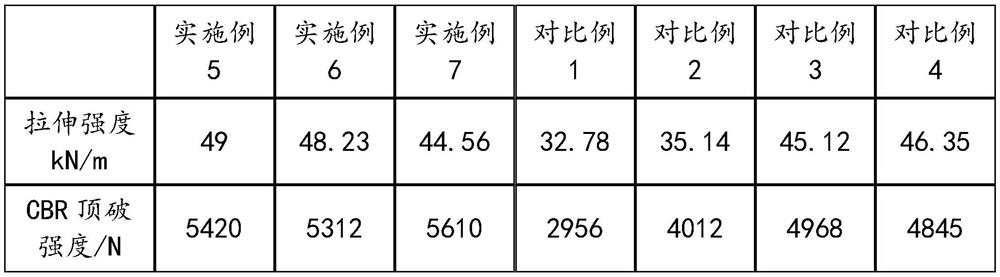

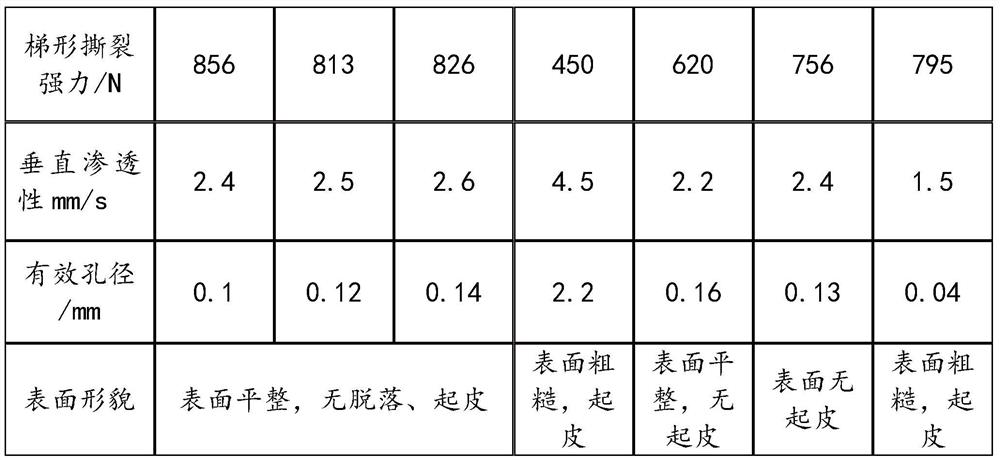

Examples

Embodiment 1

[0034] Modified calcium sulfate whiskers are made by the following steps:

[0035] Add 5g of titanate coupling agent into a three-necked flask and add 25mL of acetone to dilute, then add 10g of calcium sulfate whiskers into the flask, heat to 70°C, condense, reflux, and magnetically stir for 7 hours. After the reaction, the product is After suction filtration, the filter cake after suction filtration was washed twice with 30 mL of ethanol solution, and then the product was placed in a vacuum drying oven and dried at 50° C. for 14 hours to obtain modified calcium sulfate whiskers.

Embodiment 2

[0037] Nano-TiO 2 Made by following steps:

[0038] Step C1, add 1.25mmol of titanium tetrachloride into the autoclave, add 20.3mmol of 3,5-dimethylpiperidine, 6.5mg of KH-570 and 60mmol of deionized water and stir and mix for 0.5 hours, then put the reaction kettle on the temperature setting Heated in an oven set at 170°C for 4 days, then took out the reactor and cooled it to room temperature naturally to obtain the product;

[0039] Step C2, the product is separated by centrifugation for 20 minutes, the precipitate is dispersed in 20ml of absolute ethanol and ultrasonically oscillated for 10-20 minutes, then placed in a vacuum drying oven and dried at 60-70°C for 5-6 hours to obtain Nano-TiO 2 .

Embodiment 3

[0041] Modified polyvinylidene fluoride is made by the following steps:

[0042] Step D1, take 3g of polyvinylidene fluoride in a flask, add 20mL of N-methylpyrrolidone, stir and mix, add 2mL of tetraethylammonium hydroxide solution in a nitrogen atmosphere, heat for 30 minutes, then raise the temperature to 110°C, and keep it warm for 10 minutes , to obtain polyvinylidene fluoride solution;

[0043] In step D2, add 2 g of acrylic acid and 10 mg of benzoyl peroxide to 15 mL of N-methylpyrrolidone successively, stir and mix, add 8 mL of the polyvinylidene fluoride solution prepared in step D1 to the mixture, and control the reaction temperature to 70 ° C for 30 Minutes, after the reaction is over, wash the product with deionized water for 3 times, then extract it with absolute ethanol for 24 hours to remove unreacted acrylic acid, after extraction, put it in a vacuum oven at 75°C and dry it for 10 hours to obtain Modified polyvinylidene fluoride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com